Flux Core Wire - Low Spatter, Strong Welds, Gasless MIG

flux core wire,aluminum flux core wire is a key solution in the industrial goods industry, specifically within welding materials and Flux cored wire. This article explores how HEBEI YUJINHONG TECHNOLOGY CO.,LTD. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- flux core wire,aluminum flux core wire Overview

- Benefits & Use Cases of flux core wire,aluminum flux core wire in Flux cored wire

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in industrial goods

- Conclusion on flux core wire,aluminum flux core wire from HEBEI YUJINHONG TECHNOLOGY CO.,LTD.

flux core wire,aluminum flux core wire Overview

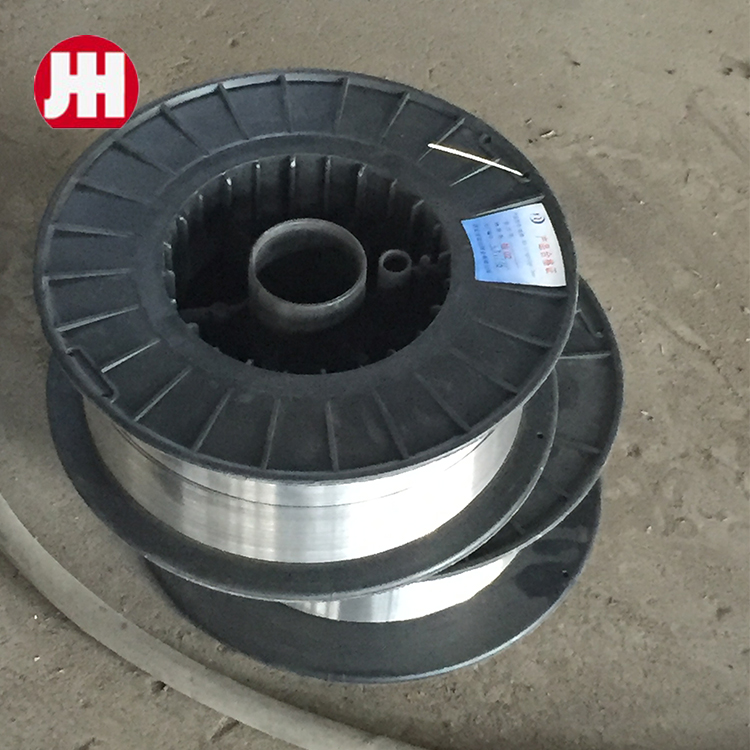

Flux cored wire is a tubular, continuously fed welding consumable that contains a carefully engineered flux formulation at its core. In industrial goods—especially the welding materials segment—flux cored wire is relied upon for high deposition rates, strong mechanical properties, and robust all-position performance. Gas-shielded (FCAW-G) wires such as typical AWS A5.20 E71T-1C/1M grades deliver excellent bead appearance and low spatter with CO2 or mixed gas shielding, while self-shielded (FCAW-S) variants enable reliable welding outdoors where shielding gas is impractical.

Technical options commonly span diameters from 0.8 to 1.6 mm, with precision layer-wound spools (e.g., 5 kg, 15 kg, 20 kg). Polarity is typically DCEP, and process parameters can be tuned for high travel speeds and minimized cleanup. While aluminum flux core wire is more specialized, it can support specific maintenance or field applications where traditional shielding methods are constrained—best selected with application engineering guidance.

HEBEI YUJINHONG TECHNOLOGY CO.,LTD. is a reliable manufacturer in this space, offering consistent flux fill ratios, tight casting/helix tolerances for smooth feeding, and robust lot traceability. For B2B decision makers, the company’s focus on manufacturing discipline and quality control translates into predictable weld performance and process stability on the shop floor.

Benefits & Use Cases of flux core wire,aluminum flux core wire in Flux cored wire

Across structural steel fabrication, shipbuilding, heavy equipment, pressure vessels, and infrastructure projects, flux core wire drives productivity with high deposition rates and excellent out-of-position capability. FCAW-G grades are preferred where shielding gas is available, offering smooth arc characteristics and clean slag removal. Self-shielded wires excel outdoors—construction sites, repair work, and wind-exposed environments—ensuring robust arc stability and strong welds without cylinder logistics.

Aluminum flux core wire is a niche but valuable option for certain repair and maintenance scenarios or field jobs where a shielding gas setup is impractical. In such cases, it can help achieve acceptable joints or brazed repairs on select aluminum components, provided surface preparation is meticulous and parameters are dialed in carefully. For critical or high-spec aluminum work, many operations still prefer gas-shielded MIG with solid wire; therefore, choosing aluminum flux core wire should be an engineering-driven decision.

HEBEI YUJINHONG TECHNOLOGY CO.,LTD. differentiates with consistent wire geometry for low spatter, optimized slag systems for easier post-weld cleanup, and tailored flux chemistries aimed at stable arc starts and minimal porosity. The company collaborates with end users to match the wire to the application—mild steel, low-alloy, and specialized requirements—helping industrial teams hit throughput and quality targets with fewer process interruptions.

Cost, Maintenance & User Experience

Total cost of ownership in welding is shaped by more than the price per kilogram of wire. Deposition efficiency, arc-on time, operator productivity, shielding gas consumption (if applicable), and rework rates all influence real ROI. Flux core wire often reduces passes and saves time, which lowers labor cost per meter of weld. Clean slag detachment and controlled spatter can cut grinding and post-weld cleanup—freeing capacity for value-added tasks.

From a maintenance perspective, storing wire in dry, temperature-stable conditions helps prevent moisture pickup and preserves performance. Keep spools sealed until use and follow best practices for wire feeding—use clean liners, correct drive rolls, and appropriate tension. These basics maintain arc stability and extend consumable life. Users commonly note the smooth feedability of well-made flux core wire and the practical benefits of layer-wound spools that minimize tangling and downtime.

Industrial buyers working with HEBEI YUJINHONG TECHNOLOGY CO.,LTD. appreciate dependable batch-to-batch consistency, clear technical data, and responsive after-sales support. When paired with process guidance—parameter windows, suggested shielding gases, and technique tips—customers typically realize fewer arc restarts, more uniform bead profiles, and more predictable schedules, all of which feed directly into improved project economics.

Sustainability & Market Trends in industrial goods

Welding operations are under pressure to boost productivity while shrinking environmental footprints. Flux core wire supports this shift in multiple ways: higher deposition rates reduce energy per unit of weld metal, self-shielded options minimize shielding gas logistics, and cleaner welds can lower grinding-related energy and consumables. Many buyers also value recyclable packaging, returnable spools, and transparent documentation for compliance initiatives such as RoHS/REACH.

Market trends show growing demand from infrastructure renewal, shipbuilding, energy projects, and heavy equipment manufacturing—sectors where FCAW’s productivity advantages are compelling. Automation and cobot welding continue to rise, favoring wires with consistent mechanical properties, low spatter, and reliable feedability. HEBEI YUJINHONG TECHNOLOGY CO.,LTD. pursues forward-looking R&D in flux formulations, works to reduce fume generation where possible, and emphasizes quality systems that support digital traceability and stable performance in robotic cells.

By aligning product development with process efficiency and sustainability targets, HEBEI YUJINHONG TECHNOLOGY CO.,LTD. helps welding operations meet stricter environmental expectations without sacrificing throughput or weld integrity—an essential balance for B2B decision makers navigating modern industrial requirements.

Conclusion on flux core wire,aluminum flux core wire from HEBEI YUJINHONG TECHNOLOGY CO.,LTD.

For the industrial goods sector—particularly welding materials in the Flux cored wire category—flux core wire,aluminum flux core wire delivers the productivity, versatility, and quality control that production teams demand. Whether the need is for gas-shielded, self-shielded, or specialized aluminum applications, HEBEI YUJINHONG TECHNOLOGY CO.,LTD. provides consistent products, process guidance, and reliable delivery that support stronger ROI and smoother operations.

Contact us: email: info@steeltoolschina.com

Visit our website: https://www.steeltoolschina.com

-

What is a medium-frequency pulse? What types of welding are suitable for?NewsNov.24,2025

-

Why is the overall cost of CO2 welding lower than that of shielded metal arc welding?NewsNov.21,2025

-

Welding Knowledge 6NewsNov.20,2025

-

What is a low-frequency pulse? What types of welding are they suitable for?NewsNov.19,2025

-

Why are the weld joints from CO₂ gas shielded welding of such high quality?NewsNov.18,2025

-

J506 Welding Rod - Low Hydrogen, All-Position, AC/DC E7016NewsNov.17,2025