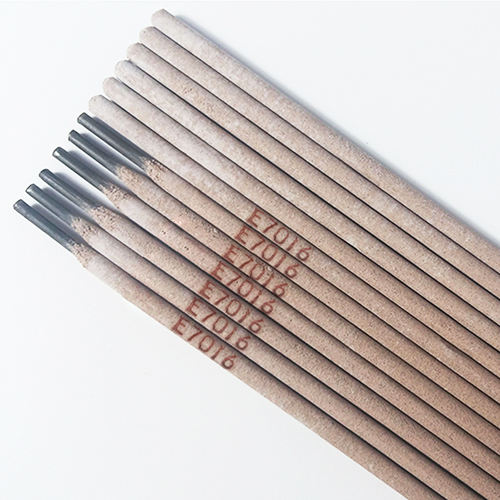

E7016 Welding Rods: High Strength Low Hydrogen for Critical Welds

The Strategic Importance of E7016 Welding Rods in Modern Industrial Fabrication

In the intricate landscape of B2B industrial fabrication and construction, the selection of appropriate welding consumables is paramount to ensuring structural integrity, operational efficiency, and long-term durability. Among the diverse array of electrodes available, e7016 welding rods stand out as a critical choice for high-strength, low-alloy (HSLA) steel applications. These basic-coated, low-hydrogen electrodes are engineered to deliver superior mechanical properties and excellent crack resistance, making them indispensable in demanding sectors such as petrochemical, power generation, and heavy machinery manufacturing. Their unique flux composition ensures a stable arc, minimal spatter, and robust weld metal, crucial for environments subjected to high stresses, varying temperatures, and corrosive agents.

The global demand for advanced welding solutions continues to escalate, driven by infrastructure development, energy transition projects, and the increasing complexity of engineered structures. Industry trends point towards a growing emphasis on materials that offer not only strength but also enhanced ductility and impact toughness, particularly at sub-zero temperatures. This shift necessitates consumables like the e7016 welding rods, which are specifically designed to meet stringent international standards for performance and reliability. Manufacturers are continuously innovating to optimize the electrode's usability, arc stability, and metallurgical properties to cater to automated welding processes and specialized applications, ensuring consistent quality across diverse fabrication challenges. The push for greater energy efficiency and reduced maintenance cycles further underscores the value of high-performance electrodes capable of producing defect-free welds from the outset.

Unpacking the Technical Superiority of Electrode 7016

The classification electrode 7016 adheres to the American Welding Society (AWS) A5.1/A5.1M standard for carbon steel electrodes for shielded metal arc welding. The 'E' denotes an electrode, '70' indicates a minimum tensile strength of 70,000 psi (approximately 480 MPa), '1' signifies that it can be used in all welding positions (flat, horizontal, vertical up, overhead), and '6' represents the coating type (basic, low-hydrogen) and current suitability (AC or DCEP). This specific combination of characteristics endows the e7016 welding rod with exceptional metallurgical and mechanical performance critical for high-integrity welds.

The low-hydrogen content is particularly vital as it minimizes the risk of hydrogen-induced cracking (HIC), a common and severe problem in welding high-strength steels. The basic flux coating, rich in calcium carbonate and other deoxidizers, provides excellent slag detachability and creates a stable arc, even with challenging base metals. This results in a fine, ripple-free bead appearance and deep penetration. Furthermore, the weld metal deposited by an e7016 welding rod exhibits superior impact toughness, even at sub-zero temperatures, which is a non-negotiable requirement for applications in cryogenic vessels, offshore structures, and pipelines in cold climates.

Key Technical Specifications for E7016 Welding Rods

Precision Engineering: The Manufacturing Process of E7016 Welding Rods

The creation of high-performance e7016 welding rods is a meticulously controlled manufacturing process, ensuring consistency, quality, and adherence to stringent international standards such as ISO 2560 and AWS A5.1/A5.1M. This multi-stage process integrates advanced material science with precision engineering, designed to produce an electrode capable of delivering optimal weld characteristics.

Detailed Process Flow:

- Core Wire Preparation: The process begins with high-quality steel wire, typically a low-carbon steel, selected for its consistent chemical composition and mechanical properties. This wire undergoes drawing processes to achieve the precise diameter required for various electrode sizes. Surface cleanliness is critical to ensure proper adhesion of the flux coating and prevent contamination.

- Flux Material Preparation: The heart of the electrode 7016 lies in its basic, low-hydrogen flux coating. This coating is a carefully formulated blend of mineral ingredients, including calcium carbonate (limestone), fluorspar, ferrosilicon, ferromanganese, and cellulosic materials, along with binders like potassium silicate or sodium silicate. Each component is precisely weighed, mixed, and then ground into a fine powder. This ensures homogeneity and optimal metallurgical reactions during welding.

- Extrusion Coating: The prepared core wire is then fed into an extrusion press. The powdered flux mixture, often dampened with a silicate binder solution to form a paste-like consistency, is compacted and extruded onto the core wire under high pressure. This process ensures a uniform and concentric coating thickness around the wire. Consistency in coating thickness is crucial for arc stability and weld integrity.

- Baking and Drying: After extrusion, the coated electrodes are subjected to a rigorous baking and drying process in specialized ovens. This stage is paramount for driving off moisture and achieving the ultra-low hydrogen content that defines the `electrode 7016` classification. The temperature and duration of baking are precisely controlled to ensure proper solidification of the flux and prevent cracking. Typical baking temperatures can range from 350°C to 450°C (660°F to 840°F) for several hours.

- Tip Cleaning and Inspection: Once cooled, the electrodes undergo tip cleaning, where the flux coating is removed from one end to ensure proper electrical contact during welding. Each rod is then subjected to rigorous quality control inspections, including visual checks for coating integrity, eccentricity, and physical dimensions. Random samples are taken for mechanical testing (tensile strength, yield strength, impact toughness), chemical analysis of the deposited metal, and hydrogen content verification in accordance with international testing standards like ISO and ANSI.

- Packaging: Finally, the finished e7016 welding rods are carefully packaged in moisture-proof container111s, such as hermetically sealed cans or vacuum-sealed foil bags, to maintain their low-hydrogen characteristics until use. Proper packaging is critical to preserve the electrode's performance and extend its service life, especially for products destined for demanding industries like petrochemicals where product integrity is paramount.

Core Wire Preparation

Flux Mixing & Blending

Extrusion Coating

Baking & Drying

Quality Inspection

Application Scenarios and Technical Advantages: Where E7016 Excels

The versatility and robust performance of e7016 welding rods make them a preferred choice across a multitude of heavy industrial applications where weld integrity is non-negotiable. These electrodes are specifically designed for welding medium and high tensile strength steels, as well as low-alloy steels that are critical in various demanding sectors.

Target Industries and Typical Application Scenarios:

- Petrochemical Industry: For the fabrication of pressure vessels, pipelines, storage tanks, and heat exchangers that operate under extreme temperatures and pressures. The low-hydrogen deposit prevents HIC in critical components exposed to sour service (H2S environments), enhancing the service life and safety of installations.

- Metallurgy and Heavy Machinery: Used extensively in the construction and repair of heavy earthmoving equipment, cranes, mining machinery, and steel mill components. Its ability to weld thick sections and provide high impact strength is crucial for parts undergoing dynamic loading and abrasive wear.

- Water Supply & Drainage Infrastructure: Essential for welding large-diameter pipes, structural components of pumping stations, and water treatment facilities. The excellent corrosion resistance of the weld metal contributes to the longevity of these vital systems.

- Power Generation: Critical for power plant construction, including boiler components, turbine casings, and structural supports, especially those using HSLA steels. The consistent quality and mechanical properties ensure operational reliability and energy efficiency of power infrastructure.

- Shipbuilding and Offshore Construction: Used for welding hulls, decks, offshore platforms, and other marine structures. The ability to weld in all positions, combined with high impact toughness, is paramount for structures exposed to harsh marine environments and dynamic stresses.

Key Technical Advantages:

- Superior Corrosion Resistance: The refined microstructure and low impurity content in the weld metal contribute to enhanced resistance against various corrosive media, extending the service life of welded components.

- Exceptional Mechanical Properties: Delivers high tensile strength, yield strength, and excellent ductility. This ensures the weld joint can withstand significant operational stresses and deformations without failure.

- Low Hydrogen Content: Crucial for welding high-strength and thick section steels, drastically reducing the risk of cold cracking (hydrogen-induced cracking), which can lead to catastrophic failures. This makes the `electrode 7016` invaluable for critical applications.

- Excellent Impact Toughness: Maintains robust impact properties, even at sub-zero temperatures, which is a critical characteristic for structures operating in cold environments or subject to sudden shock loads.

- All-Positional Weldability: Offers good operability in all welding positions (except vertical down), providing flexibility for complex fabrications and repairs where positional welding is often required.

- Energy Saving Potential: Due to superior penetration and the ability to produce high-quality welds with fewer passes in certain applications, these electrodes can contribute to reduced welding time and energy consumption. The robust slag system often ensures easier slag removal, further streamlining post-weld cleaning processes.

- Long Service Life: Components welded with e7016 welding rods typically exhibit extended service lives, reducing maintenance frequency and overall operational costs, thereby demonstrating a strong return on investment for end-users.

Strategic Procurement: Vendor Comparison and Customized Solutions for E7016

When procuring e7016 welding rods, B2B decision-makers face a critical choice that impacts project quality, schedule, and cost. A thorough vendor comparison goes beyond price, encompassing factors such as product consistency, technical support, customization capabilities, and adherence to global quality standards. Leading manufacturers distinguish themselves through a commitment to R&D, stringent quality control, and comprehensive customer service.

E7016 Welding Rods Vendor Comparison (Illustrative)

Customized E7016 Solutions: Tailored for Specific Needs

Recognizing that standard products may not always meet the unique challenges of every project, specialized manufacturers offer customized e7016 welding rods. This level of service is particularly beneficial for complex projects requiring specific metallurgical properties, enhanced corrosion resistance against particular agents, or optimized performance under unusual environmental conditions. Customization options may include:

- Tailored Flux Formulations: Adjusting the flux composition to fine-tune weld metal chemistry, mechanical properties (e.g., higher impact toughness at specific temperatures), or arc characteristics for specialized base metals.

- Specific Diameters and Lengths: Producing electrodes in non-standard sizes to match automated welding systems or confined access welding scenarios.

- Special Packaging Solutions: Providing packaging designed for extreme climates, extended shelf life requirements, or specific logistical constraints, ensuring the integrity of the low-hydrogen property.

- Certification & Testing: Offering additional or specific third-party certifications and testing beyond standard requirements to meet unique project specifications or client demands.

This ability to provide bespoke solutions highlights a vendor's technical depth and commitment to partnership, delivering not just a product but a performance-guaranteed solution that aligns perfectly with project objectives.

Real-World Impact: Application Case Studies and Customer Experience

The true measure of an industrial product's efficacy lies in its performance in challenging real-world scenarios. For e7016 welding rods, their consistent reliability has garnered extensive positive feedback from engineers and fabricators worldwide. Our commitment to quality is underscored by a track record of successful projects and long-standing partnerships with leading enterprises across various sectors, demonstrating our adherence to global standards such as ISO 9001 for quality management and product-specific certifications from major classification societies like ABS, DNV, and LR.

Application Case Studies:

- High-Pressure Pipeline Project, Middle East (Petrochemical): A major energy company faced the challenge of welding high-strength steel pipelines (API 5L X65) in a demanding desert environment, requiring excellent low-temperature impact toughness and crack resistance. Utilizing our customized e7016 welding rod, the project achieved critical weld integrity, meeting stringent radiography and ultrasonic testing standards. The low-hydrogen properties proved crucial in preventing delayed cracking, ensuring the long-term safety and operational efficiency of the gas transmission network. Our technical team provided on-site support, optimizing welding parameters for the specific conditions, leading to a significant reduction in rework rates.

- Offshore Platform Fabrication, North Sea (Shipbuilding/Offshore): For the construction of critical structural nodes on an offshore drilling platform, where components are subjected to immense dynamic loads and harsh marine conditions, our `electrode 7016` was selected. The superb all-position weldability facilitated complex joint configurations, while the exceptional impact strength at -40°C guaranteed structural resilience against ice and wave forces. Post-weld inspection revealed consistently high-quality welds, contributing to the platform's classification and certification by DNV-GL. A project engineer remarked, "The consistency of these `e7016 welding rods` was instrumental in maintaining our fabrication schedule and quality benchmarks."

- Heavy Industrial Equipment Repair, Europe (Metallurgy): A large steel mill required urgent repairs to a fractured main frame component of a continuous casting machine, fabricated from quenched and tempered steel. The repair necessitated a welding consumable capable of matching the base metal's high strength and resisting hydrogen embrittlement. Our `e7016 welding rod` provided the necessary mechanical properties and low hydrogen content, enabling a reliable repair that restored the equipment to full operational capacity within a critical timeframe, minimizing costly downtime.

Trust and Transparency: FAQ, Lead Time, Warranty, and Support

Building trust with our B2B partners is at the core of our operations. We believe in complete transparency regarding our products, processes, and post-sales support. This section addresses common inquiries and outlines our commitments to ensure a seamless experience for our clients.

Frequently Asked Questions (FAQ)

What is the primary advantage of using an e7016 welding rod over other electrodes?

The primary advantage lies in its low-hydrogen, basic flux coating, which produces weld metal with excellent mechanical properties, high impact toughness (especially at low temperatures), and superior resistance to hydrogen-induced cracking. This makes it ideal for critical applications with high-strength low-alloy steels.

Can I use `electrode 7016` for welding in all positions?

Yes, the `electrode 7016` is classified for all-position welding, except for vertical down. Its excellent arc control and slag system allow for high-quality welds in flat, horizontal, vertical up, and overhead positions, offering great flexibility in fabrication and repair scenarios.

How should e7016 welding rods be stored to maintain their low-hydrogen property?

To preserve their low-hydrogen characteristics, `e7016 welding rods` must be stored in dry, moisture-proof conditions. Ideally, they should be kept in hermetically sealed container111s or heated electrode ovens (holding ovens) at recommended temperatures (e.g., 100-150°C / 212-300°F) after opening the original packaging and before use.

Lead Time and Fulfillment

We understand the critical importance of timely delivery in industrial projects. Our robust supply chain and optimized manufacturing processes enable us to offer competitive lead times. For standard orders of e7016 welding rods, typical lead times range from 2-4 weeks, depending on order volume and destination. Customized solutions or very large-volume orders may require slightly longer, which will be communicated transparently at the quotation stage. We utilize a global logistics network to ensure efficient and reliable delivery worldwide.

Warranty Commitments

All our Customized E7016 Welding Rods Electrodes are manufactured under strict quality control protocols and are backed by a comprehensive warranty against manufacturing defects. We guarantee that our products meet or exceed the specified AWS, ISO, and other relevant international standards as outlined in our product data sheets. Our warranty period typically covers 12 months from the date of purchase, provided the products are stored and used according to our recommendations. For detailed warranty terms and conditions, please refer to our official documentation.

Dedicated Customer Support

Our commitment extends beyond product delivery. We offer dedicated technical support to assist our clients with product selection, application guidance, troubleshooting, and optimization of welding procedures. Our team of experienced welding engineers is available for consultation via phone, email, or scheduled virtual meetings. For complex projects or specific on-site challenges, tailored technical assistance can also be arranged. We pride ourselves on providing responsive and knowledgeable support, ensuring our clients achieve optimal results with our products.

Conclusion: Empowering Industrial Excellence with E7016 Electrodes

The role of high-quality welding consumables, particularly e7016 welding rods, cannot be overstated in achieving industrial excellence. Their unique combination of mechanical strength, low-hydrogen characteristics, and versatility in application positions them as an indispensable tool for engineers and fabricators tackling critical projects involving high-strength low-alloy steels. From the rigorous demands of the petrochemical industry to the exacting standards of heavy machinery manufacturing, these electrodes consistently deliver reliable, high-integrity welds that stand the test of time and extreme operational conditions.

As industries continue to evolve, with an increasing focus on sustainability, efficiency, and enhanced material performance, the demand for specialized and customized welding solutions will only grow. Partnering with a manufacturer that not only adheres to the highest international quality standards but also offers comprehensive technical support and tailored product development, ensures that projects benefit from cutting-edge welding technology. Investing in premium e7016 welding rods is an investment in the long-term integrity, safety, and performance of vital industrial assets, driving operational success and minimizing costly downtimes.

Authoritative Citations

- American Welding Society (AWS) A5.1/A5.1M:2017, Specification for Carbon Steel Electrodes for Shielded Metal Arc Welding.

- ISO 2560:2020, Welding consumables - Covered electrodes for manual metal arc welding of non-alloy and fine grain steels - Classification.

- Bhadeshia, H. K. D. H. (2006). Steels for nuclear applications. Materials Science and Technology, 22(10), 1146-1153.

- The Welding Institute (TWI), "Hydrogen cracking," [Online]. Available: https://www.twi-global.com/technical-knowledge/faqs/faq-what-is-hydrogen-cracking.

- Moden, B., & Gittos, M. F. (2018). Welding metallurgy: carbon and low alloy steels. CRC Press.

-

High-Quality Welding Electrodes 4.0mm*400mm for Industrial Use | Steel Tools ChinaNewsNov.24,2025

-

Explore the Benefits and Uses of 2.6mm Welding Electrode 6013 | Global GuideNewsNov.23,2025

-

Understanding CO2 Welding Wire Price: Global Impact, Trends, and TipsNewsNov.22,2025

-

Top Guide to Welding Wires CO2 – Specifications, Benefits & Industry UsesNewsNov.22,2025

-

Comprehensive Guide to Welding Electrode 6011 – Global Applications & BenefitsNewsNov.21,2025

-

AWS E6013 Welding Rod-HEBEI YUJINHONG TECHNOLOGY CO.,LTD.|All-Position Carbon Steel ElectrodeNewsNov.21,2025