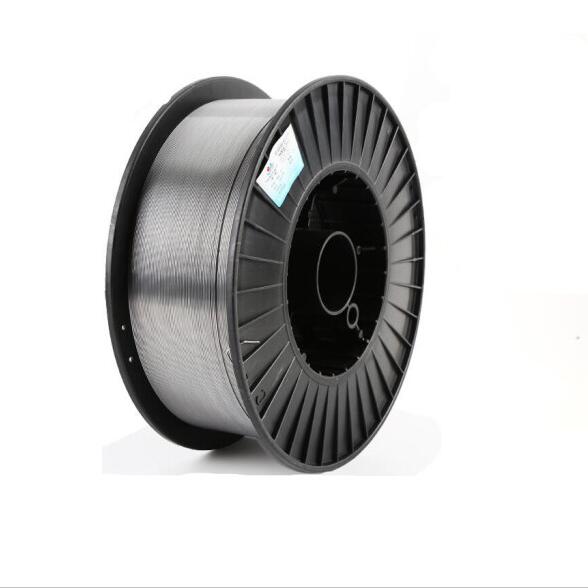

E71T GS Welding Wire: No-Gas, Low Spatter—Ready to Weld?

E71T-GS Welding Wire: A No-Gas Workhorse That Keeps Jobs Moving

If you’ve ever dragged a gas bottle across a windy site and muttered under your breath, you’ll get why e71t gs welding wire has a loyal following. It’s self-shielded, forgiving on marginal prep, and—frankly—saves the day when weather or access gets in the way. I’ve seen crews in farm fields and mobile repair vans switch to this wire and finish ahead of schedule, which is rarer than we admit.

What It Is (and Isn’t)

The E71T-GS designation (AWS A5.20) flags a gasless, flux-cored wire for all-position welding of mild steel. It lays a smooth, stable arc with easy slag removal—great for thin-gauge steel, gates, trailers, HVAC brackets, light fabrication, even automotive patch panels. It’s not a substitute for structural wire tested to more stringent impact requirements, but for everyday steel, it’s a reliable go-to. Many customers say it “just lights and flows,” even on smaller 110/120V machines.

| Spec | E71T-GS WELDING WIRE (typical) |

|---|---|

| AWS/ASME | AWS A5.20 E71T-GS; suitable under AWS D1.1 prequalified WPS when permitted |

| Diameters | 0.8 / 0.9 / 1.0 mm (0.030 / 0.035 / 0.040 in) |

| Polarity | DCEN (straight polarity) |

| Mechanicals | UTS ≈ 480–550 MPa (70–80 ksi); YS ≈ 400–460 MPa; elong. ≈ 18–24% (real-world may vary) |

| Positions | All-position FCAW-S; excels out-of-position with short arc lengths |

| Shielding | Self-shielded; no external gas required |

How It’s Made: Materials, Methods, and Testing

Core blend typically includes rutile, deoxidizers, arc stabilizers, and iron powder packed into a low-carbon steel strip. The strip is formed (U/O), filled, closed, drawn to size, and spooled. Some lots are copper-coated; others rely on precise lubrication to ensure feedability. QC checks include wire cast/helix, diameter tolerance, diffusible hydrogen (per AWS A4.3 methods), and weld procedure coupons—macroetch, fillet break, bends. Lots ship with MTC and ISO 9001 traceability. Service life of the weld? With proper surface prep and paint, outdoor repairs regularly last years—decades in mild environments.

Trends I’m Seeing

There’s a noticeable shift to self-shielded FCAW in small fab shops and field maintenance—mostly because shielding gas costs and logistics keep creeping up. Surprisingly, even hobby welders are using e71t gs welding wire for first passes outdoors, then switching to GMAW indoors for cosmetics.

Application Scenarios

- Windy job sites where gas shielding is unreliable

- Automotive patching (thin steel) with short stitch technique

- Farm equipment, gates, fencing, light frames, trailers

- Emergency repairs from service trucks—fast, portable, productive

| Vendor | AWS Class | Dia. Range | Lead Time | Certs | Customization |

|---|---|---|---|---|---|

| SteelToolsChina (Origin: NO.368 YOUYI NORTH STREET, XINHUA DISTRICT, SHIJIAZHUANG CITY, CHINA) | E71T-GS | 0.8–1.2 mm | ≈ 7–15 days (stock/size dependent) | ISO 9001; CE on request | Private label, OEM spools, kit bundles |

| Blue Demon (reference) | E71T-GS | 0.8–1.0 mm | Retail availability | Typical OEM QA | Limited packaging options |

| Generic Importer | E71T-GS | 0.9–1.0 mm | Uncertain | Varies | Minimal |

Real-World Notes and Case Snippets

Case 1: A fencing contractor switched to e71t gs welding wire for windy hillside installs—reported 25–30% time savings vs GMAW with windshields. Case 2: Auto hobbyist spot-stitching 20–22 ga panels: less burn-through using 0.8 mm wire, short stick-out, and quick trigger pulls. Not perfect every time, but the feedback was consistently positive.

Parameters and Tips

- Polarity: DCEN, short stick-out (~10–15 mm)

- Voltage/Wire feed: start low; tune for crisp, steady crackle

- Thin sheet: stitch or weave lightly; let slag insulate between passes

- Finish: chip/brush slag; prime/paint to extend service life significantly

Compliance, Testing, and Documentation

Manufactured to AWS A5.20 E71T-GS with lot testing; typical WPS/PQR support per AWS D1.1 where applicable. ISO 9001 quality system; EN ISO 17632 reference data available. Diffusible hydrogen levels are controlled by flux chemistry and storage—always keep spools dry, to be honest.

Customization

Spool sizes (1 kg, 5 kg, 15 kg), private-label cartons, barcoding, and mixed consumable kits can be arranged. For OEMs adopting e71t gs welding wire across multiple plants, consistent lot coding and mechanicals are the real win.

Sources and Standards:

-

High-Quality Welding Electrodes 4.0mm*400mm for Industrial Use | Steel Tools ChinaNewsNov.24,2025

-

Explore the Benefits and Uses of 2.6mm Welding Electrode 6013 | Global GuideNewsNov.23,2025

-

Understanding CO2 Welding Wire Price: Global Impact, Trends, and TipsNewsNov.22,2025

-

Top Guide to Welding Wires CO2 – Specifications, Benefits & Industry UsesNewsNov.22,2025

-

Comprehensive Guide to Welding Electrode 6011 – Global Applications & BenefitsNewsNov.21,2025

-

AWS E6013 Welding Rod-HEBEI YUJINHONG TECHNOLOGY CO.,LTD.|All-Position Carbon Steel ElectrodeNewsNov.21,2025