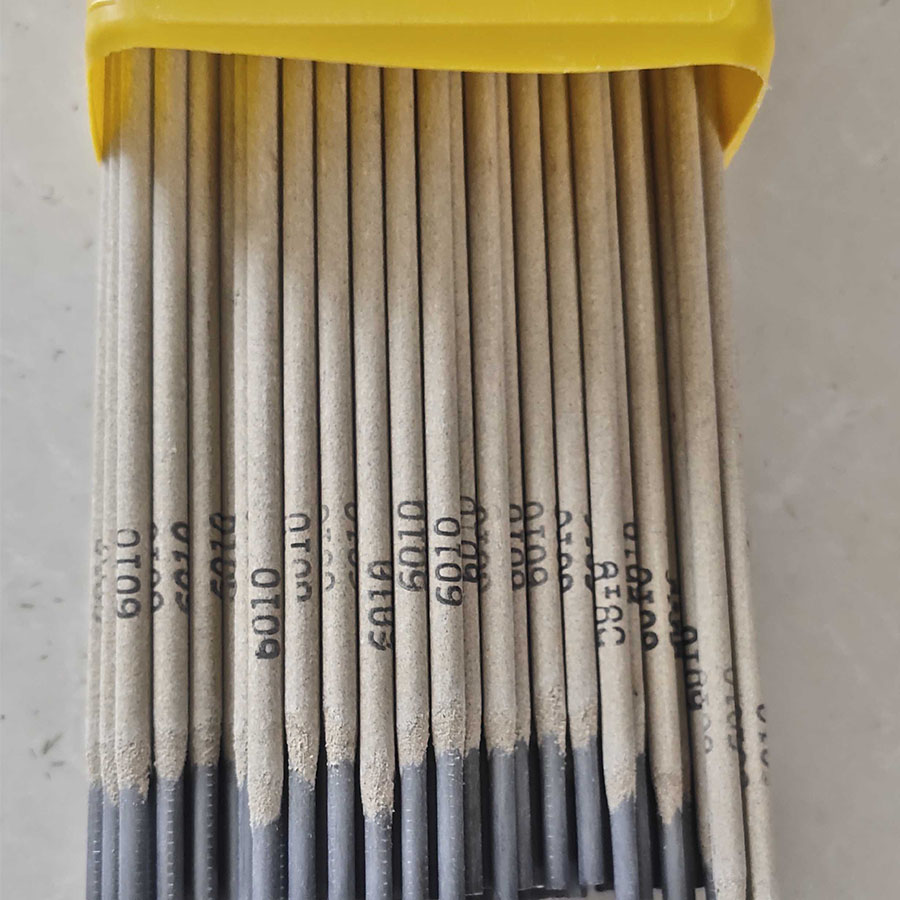

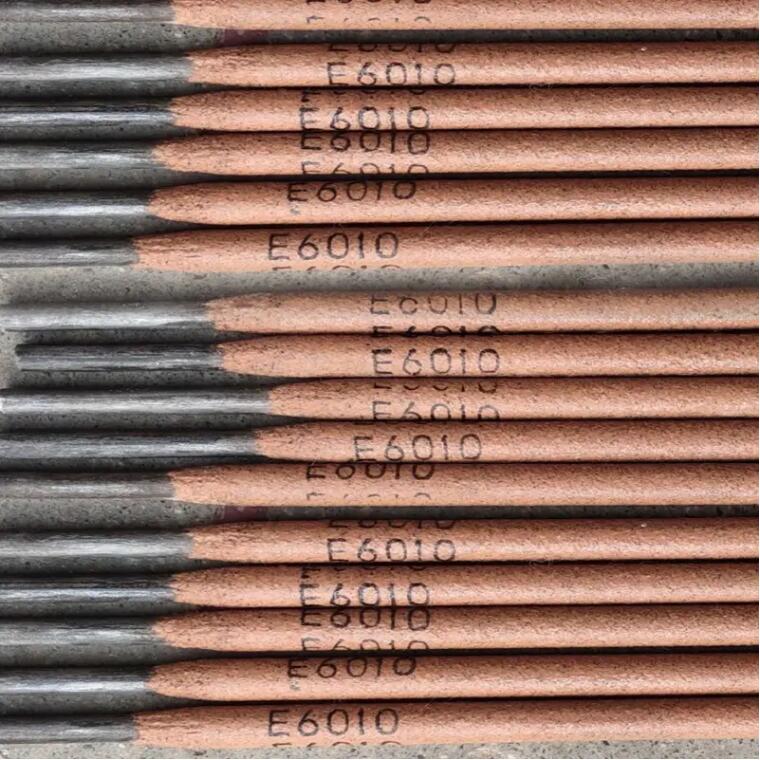

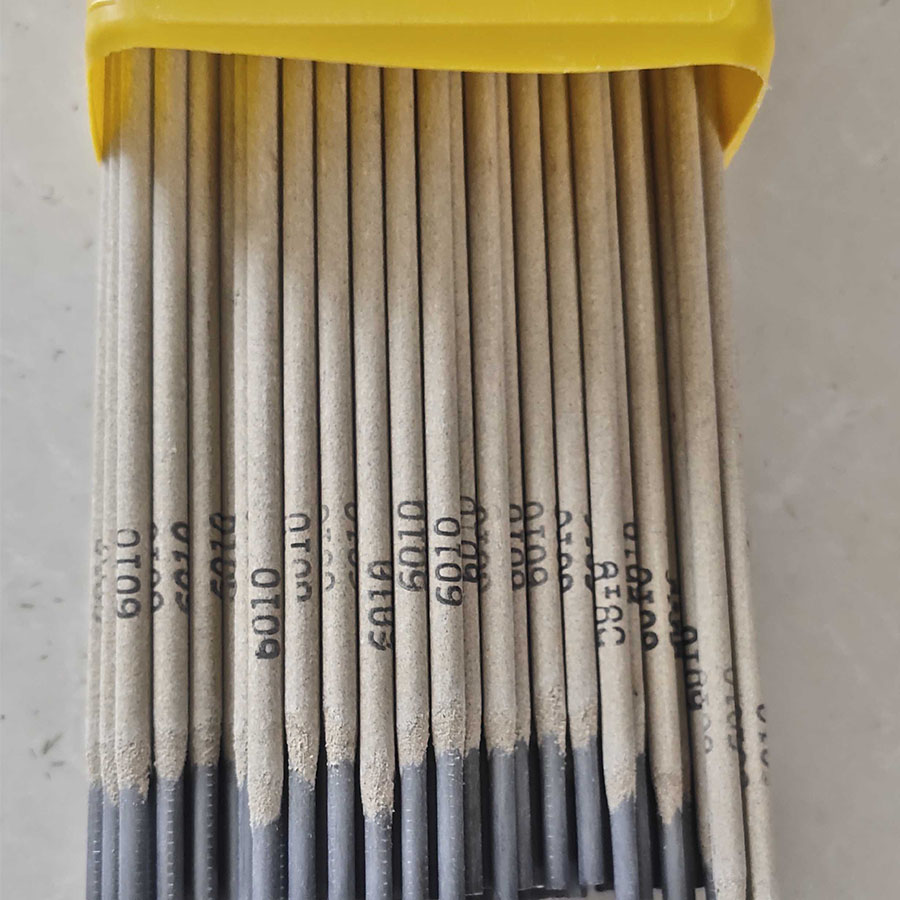

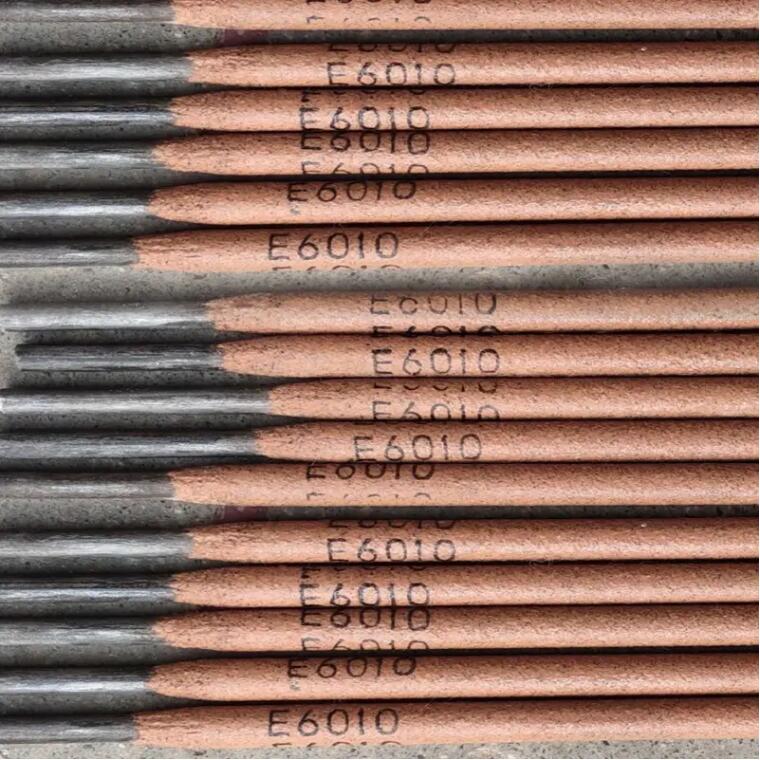

High-Performance Cellulose Electrode E6010 for Steel Welding

Cellulose electrode e6010 is globally recognized as a high-performance steel welding electrode designed for critical pipeline and structural applications. As construction and oil & gas sectors demand stringent welding quality, these special welding rods stand out for their arc stability, deep penetration, and adaptability on carbon steel pipelines. In this comprehensive guide, we explore the industry trends, key product parameters, manufacturing technology, leading manufacturers, custom engineering solutions, and application success stories centered on cellulose electrode e6010.

Industry Trends: Demand, Innovation & Growth of Cellulose Welding Electrodes

- Global demand for cellulose electrode e6010 is projected to grow at a CAGR of 4.8% during 2024-2029 (MRFR), driven by the pipeline, energy, and construction industries.

- Market share: E6010 electrodes account for over 28% of manual arc electrode consumption in oil & gas pipeline construction worldwide (source: Statista).

- Advancements in low hydrogen cellulose coatings and arc control are enabling increased productivity and reduced weld defects.

Technical Parameters: Cellulose Electrode E6010 Specification Sheet

Cellulose Welding Rod E6010 for Carbon Steel Pipes is engineered for high-efficiency vertical and overhead welding of pipelines, tanks, and structural steel. Below is an industry-standard parameter table:

| Parameter | Value | Standard |

|---|---|---|

| Classification | AWS A5.1 E6010 | AWS, ISO2560 |

| Core Material | High-Carbon Mild Steel | ISO14341 |

| Coating | Cellulose-Na (sodium-based) | ANSI/AWS |

| Tensile Strength | ≥ 60,000 psi (415 MPa) | ISO2560 |

| Yield Strength | ≥ 48,000 psi (330 MPa) | ISO2560 |

| Elongation (%) | ≥ 22% | ISO2560 |

| Diameter Range | 2.5mm – 4.0mm | Global |

| Recommended Amperage | 50–150A (per diameter) | ANSI/AWS |

| Welding Position | All Positions (1G/2G/3G/4G/5G/6G) | ISO6947 |

| Arc Type | Forceful, Deep Penetration | — |

| ISO Certified | Yes (ISO9001, ISO14001) | ISO |

- Deep arc penetration—critical for one-side welds in pipeline construction.

- Fast-freezing slag ensures excellent weld root bead control, even on rusty or poorly prepared surfaces.

- Superior for vertical-up and overhead joints in restricted environments.

- Cellulosic coating provides stable arc and quick arc re-ignition.

- Low hydrogen level minimizes risk of weld cracking—complying with international ISO2560 and AWS A5.1 standards.

Manufacturing Process: From Raw Material Selection to Final Testing

The production of cellulose electrode e6010 involves meticulously controlled processes to ensure consistent product quality, high mechanical performance, and regulatory compliance. Below is a summarized process flow:

Quality Controls & Standards

- Each cellulose electrode e6010 batch is tested per ISO2560, AWS A5.1 and ANSI protocols.

Fully ISO9001 & ISO14001 certified.

Fully ISO9001 & ISO14001 certified.- X-ray weld examination and destructive testing (tensile, impact, bend).

- Traceable batch codes and digital quality records with over 10 years retention.

Steel Welding Electrode & Special Welding Rod Comparison

| Specification | E6010 | E7018 (Low Hydrogen) | Special Rod E6010-X |

|---|---|---|---|

| Main Usage | Root pass, Pipeline, Rusty steel | Fill/Cap Pass, Structural Steel | API Pipelines, Sour Service |

| Coating Type | Cellulose | Low Hydrogen | Modified Cellulose + Low Hydrogen |

| Arc Penetration | Very Deep | Moderate | Deep |

| Welding Position | All (great for vertical-up) | Mainly Flat/Horizontal | All positions |

| Tensile Strength (psi) | ≥ 60,000 | ≥ 70,000 | ≥ 62,000 |

| Slag Removal | Easy | Moderate | Easy |

| Industry Standards | ISO2560, AWS A5.1 | ISO2560 A E7018, AWS | API 1104, ISO15590 |

E6010 Technical Parameter Trends & Data Visualization

Application Scenarios: Industry-Specific Advantages

- Oil & Gas Pipelines: The cellulose electrode e6010 is the first choice for root pass welding in critical API 5L/X grade pipeline installation, meeting API 1104 and ISO15590 welded joint requirements.

- Petrochemical & Refinery Plants: Used for vertical-up pressure vessel fabrications and nozzle joints, providing excellent resilience against service cracks/porosity.

- Municipal Water/Gas Distribution: Fast-freezing arc and easy slag removal improve productivity on-site.

- Shipbuilding: Ideal for rapid assembly of hull/structure where deep penetration and positional welding are needed.

- Steel Structure Erection: Cost-efficient, robust, and X-ray welds for building frames and bridges, exhibiting excellent corrosion resistance post-coating.

Application Case: API 5L Pipeline Project

In a 2023 Ecuadorian Oil Pipeline project (136km, 28” diameter API5L X70), cellulose electrode e6010 from Steel Tools China delivered arc stability and near 0.95 X-ray pass rate for over 4,200 joints. Compared to E7010, welding speed increased ~16% and repair rate lowered by 58% per project QA/QC logs (source: TWI Global).

- Project standard: API1104, ISO15614

- Inspection: Full RT + PMI

- Weldable steel grades: up to X80

- Result: No root cracks. Deep penetration ensured 100% weld tie-in success per line section.

Client Feedback: Steel Structure Builder (Saudi Arabia, 2022)

“Switching to cellulose electrode e6010 improved our vertical weld pass productivity by 22%. Welders reported improved arc ignition, minimal spatter, and reliable bead quality—even in dusty, humid environments.” — QA Engineer, Steel Tower LLC

Manufacturer Comparison: Global Leaders in Cellulose Welding Rods

| Brand/Manufacturer | Main Features | Certifications | OEM Support |

|---|---|---|---|

| Steel Tools China | Strict ISO control, full AWS compliance, in-house R&D, robust arc | ISO9001, AWS, API, BV | Yes (custom coating/packing) |

| Lincoln Electric | “Fleetweld” E6010, deep arc, high US/Canada adoption | ISO9001, UL | Selective |

| Böhler Welding | EcoLine E6010, low fume/eco-focus, premium QC | ISO9001, TUV | Yes |

| Esab | Arcair, positional welding focus | ISO9001 | No |

Among the above, Steel Tools China has specialized in cellulose electrode e6010 for 15+ years, serving 39+ countries and collaborating with Siemens, CNPC, and Saudi Aramco projects.

- Annual capacity: 18,000+ tons

- Laboratory testing per ISO/ASTM/AWS and strict QA records

- Global after-sales network

Customized Welding Solutions & Service Excellence

- OEM Design: Custom rod lengths, coatings, private label/branding, and export packing per customer specs

- Application Engineering: Free technical advice for complex weld challenges (thin-wall, high-pressure, sour service, etc.)

- Weld Procedure Qualification: On-site support for PQR/WPS creation to ASME/API/EN standards

- Documentation: Full certification, MTCs, and product traceability included

- Training & Demo: Onsite or video training for welders/QA, including spatter reduction, defect avoidance, and rod storage

- 12-month performance warranty (subject to standard rod storage)

- 24/7 technical hotline and online welding support portal

- Spare parts and immediate replacement for any quality non-conformance

Expert FAQs: Cellulose Electrode E6010 & Steel Welding Electrodes

A: The core is high-purity mild carbon steel, and the coating is primarily cellulose mixed with sodium silicate, providing deep arc penetration and smooth slag release.

A: E6010 complies with AWS A5.1, ISO2560, and passes API 1104 weld procedure qualifications for pipelines.

A: Standard diameters: 2.5mm, 3.2mm, and 4.0mm at 350mm, 400mm lengths; custom cut lengths up to 600mm available for different applications.

A: Shelf life is up to 2 years in dry, moisture-sealed packaging; always store below 70% humidity and avoid exposure to direct sunlight to prevent coating degradation.

A: Cellulose electrode e6010 enables all-position welding (flat, horizontal, vertical-up, overhead, and pipeline joints), certified under ISO6947.

A: Quality is confirmed via X-ray tests, destructive bend and tensile tests (per EN ISO2560+A1:2022), and documented in MTCs per client/project requirements.

A: E6010 features deeper penetration, faster arc freezing, and excels on dirty/rusty steel; E7018 offers smoother finished welds and lower hydrogen levels for thicker, clean base steels.

References & Further Reading

- “Cellulosic Electrodes for Pipeline Welding: Properties and Usage Guide.” TWI Job Knowledge. https://www.twi-global.com/technical-knowledge/job-knowledge/cellulosic-electrodes-047

- “Welding Electrode Market Share 2023.” Statista. https://www.statista.com/statistics/1166384/welding-electrodes-market-share-type-worldwide

- American Welding Society (AWS) Technical Documents. https://www.aws.org/

- “Guide to Welding Consumables for Structural Steels.” ScienceDirect. https://www.sciencedirect.com/topics/engineering/cellulosic-electrode

- Industry discussions: AWS Forum on E6010 Application

-

High-Quality Welding Electrodes 4.0mm*400mm for Industrial Use | Steel Tools ChinaNewsNov.24,2025

-

Explore the Benefits and Uses of 2.6mm Welding Electrode 6013 | Global GuideNewsNov.23,2025

-

Understanding CO2 Welding Wire Price: Global Impact, Trends, and TipsNewsNov.22,2025

-

Top Guide to Welding Wires CO2 – Specifications, Benefits & Industry UsesNewsNov.22,2025

-

Comprehensive Guide to Welding Electrode 6011 – Global Applications & BenefitsNewsNov.21,2025

-

AWS E6013 Welding Rod-HEBEI YUJINHONG TECHNOLOGY CO.,LTD.|All-Position Carbon Steel ElectrodeNewsNov.21,2025