Jan . 29, 2025 01:36

Back to list

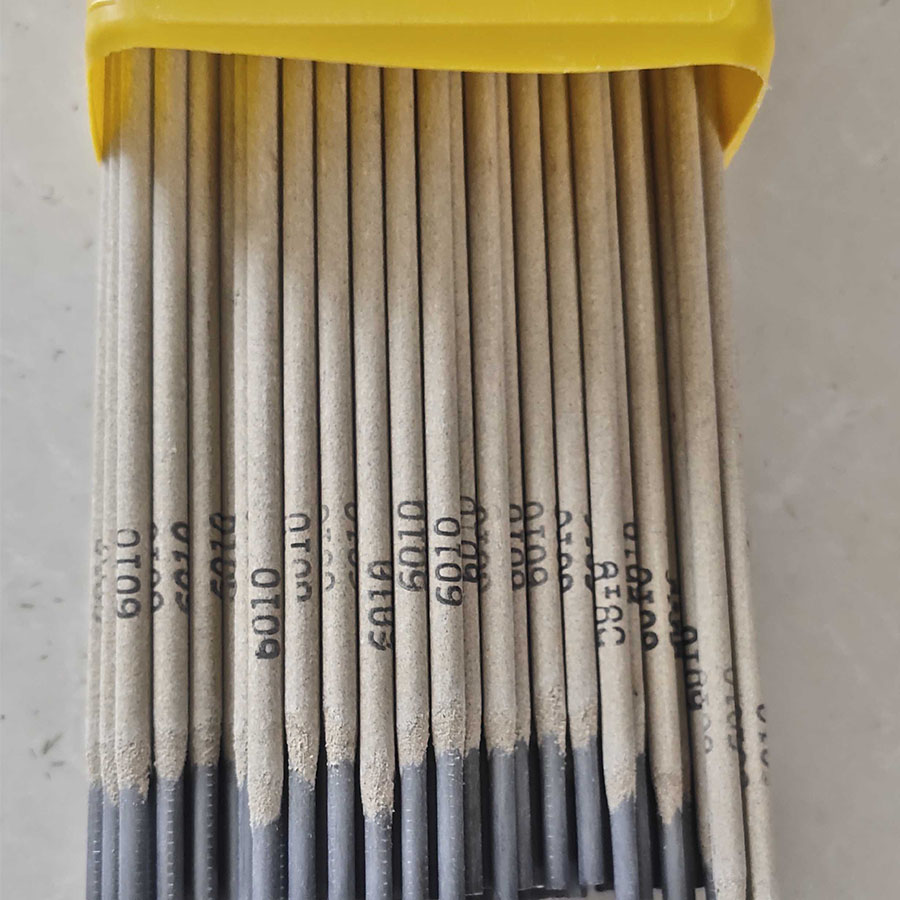

1 8 6011 welding rod

When considering the best materials for welding projects, the 6011 welding rod often emerges as a premier choice for both amateur welders and seasoned professionals. This electrode is renowned for its versatility, reliability, and efficiency in a wide array of welding applications.

Experts frequently commend the 6011 rod for its quick-freeze characteristic. This feature allows the molten pool to solidify rapidly, which is crucial during out-of-position welding or in environments where controlling the weld pool is challenging. Such a property empowers the welder with greater control over the welding process, minimizing defects and resulting in a high-quality weld that meets professional standards. When it comes to authority in the field, industry veterans often trust the 6011 rod due to its longstanding reputation for dependability. It's selected by experts in numerous sectors not just because of its performance, but also owing to decades of established reliability—this rod has consistently conformed to the rigorous demands of professional welding tasks. On the subject of trustworthiness, welders can rely on the consistency of 6011 rods available in the market due to stringent quality control from reputable manufacturers. They are produced following standardized specifications that ensure each rod performs uniformly, thereby removing the unpredictability that could compromise project outcomes. In conclusion, the 6011 welding rod stands as a beacon of efficiency, versatility, and reliability in the welding community. From reducing preparation times to delivering robust welds in diverse conditions, this electrode meets and often exceeds the expectations of professionals. Its exceptional attributes cater to the needs of both novice and veteran welders, cementing its place as an essential tool in any welder's kit. Whether you're working on maintenance projects, new construction, or complex repairs, the 6011 welding rod is an investment in quality and performance that supports skilled craftsmanship across a multitude of applications.

Experts frequently commend the 6011 rod for its quick-freeze characteristic. This feature allows the molten pool to solidify rapidly, which is crucial during out-of-position welding or in environments where controlling the weld pool is challenging. Such a property empowers the welder with greater control over the welding process, minimizing defects and resulting in a high-quality weld that meets professional standards. When it comes to authority in the field, industry veterans often trust the 6011 rod due to its longstanding reputation for dependability. It's selected by experts in numerous sectors not just because of its performance, but also owing to decades of established reliability—this rod has consistently conformed to the rigorous demands of professional welding tasks. On the subject of trustworthiness, welders can rely on the consistency of 6011 rods available in the market due to stringent quality control from reputable manufacturers. They are produced following standardized specifications that ensure each rod performs uniformly, thereby removing the unpredictability that could compromise project outcomes. In conclusion, the 6011 welding rod stands as a beacon of efficiency, versatility, and reliability in the welding community. From reducing preparation times to delivering robust welds in diverse conditions, this electrode meets and often exceeds the expectations of professionals. Its exceptional attributes cater to the needs of both novice and veteran welders, cementing its place as an essential tool in any welder's kit. Whether you're working on maintenance projects, new construction, or complex repairs, the 6011 welding rod is an investment in quality and performance that supports skilled craftsmanship across a multitude of applications.

Previous:

Next:

Latest news

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025

-

Premium E316L Welding Rod for 316L Stainless SteelNewsAug.06,2025