Feb . 01, 2025 02:02

Back to list

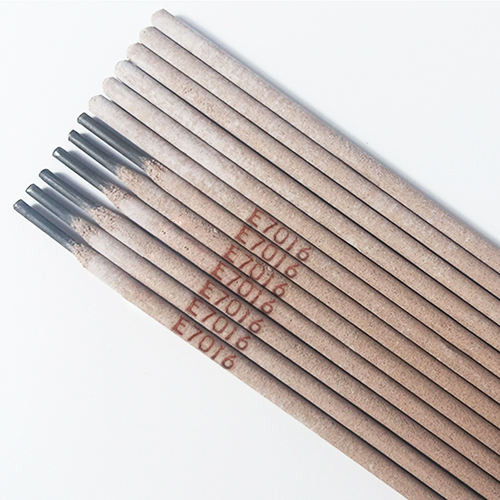

1/8 inch 7018 welding rod

The 1/8 inch 7018 welding rod is widely recognized among welders for its versatility and reliability, especially in demanding construction environments. From experienced artisans to industry professionals, this welding rod consistently delivers quality results due to its unique composition and performance features.

Testimonials from seasoned welders repeatedly underscore the high level of satisfaction achieved when using the 7018 electrode. They highlight its exceptional penetration, which ensures deep fusion with the base metal, and the aesthetically pleasing bead profile, which minimizes post-weld clean-up. This efficiency in both the process and the results empowers the professional welder to deliver superior output with less fatigue. Expert discussions further delve into the rod's ability to handle a variety of base metals, most notably mild steel. The electrode's compatibility with AC and DC welding machines adds another dimension of flexibility, permitting welders with different setups to benefit from its capabilities without additional equipment investments. Moreover, for industries where regulatory compliance is paramount, the 7018 welding rod provides assurance through its adherence to stringent certification standards, often required by construction codes and regulations. This peace of mind fosters trust not only with clients but also among team members, knowing that a robust, compliant weld is achieved every time. In summary, the 1/8 inch 7018 welding rod stands as a quintessential product for welding professionals. Its combination of low-hydrogen content, packaging integrity, and excellent welding performance elevates it above other rods in the market. The outcomes are dependable, presenting professionals with the confidence needed to tackle complex projects efficiently, which is why it's held in high esteem both in field applications and technical discussions. This unwavering reliability continues to cement its status as an indispensable tool in the toolkit of expert welders worldwide.

Testimonials from seasoned welders repeatedly underscore the high level of satisfaction achieved when using the 7018 electrode. They highlight its exceptional penetration, which ensures deep fusion with the base metal, and the aesthetically pleasing bead profile, which minimizes post-weld clean-up. This efficiency in both the process and the results empowers the professional welder to deliver superior output with less fatigue. Expert discussions further delve into the rod's ability to handle a variety of base metals, most notably mild steel. The electrode's compatibility with AC and DC welding machines adds another dimension of flexibility, permitting welders with different setups to benefit from its capabilities without additional equipment investments. Moreover, for industries where regulatory compliance is paramount, the 7018 welding rod provides assurance through its adherence to stringent certification standards, often required by construction codes and regulations. This peace of mind fosters trust not only with clients but also among team members, knowing that a robust, compliant weld is achieved every time. In summary, the 1/8 inch 7018 welding rod stands as a quintessential product for welding professionals. Its combination of low-hydrogen content, packaging integrity, and excellent welding performance elevates it above other rods in the market. The outcomes are dependable, presenting professionals with the confidence needed to tackle complex projects efficiently, which is why it's held in high esteem both in field applications and technical discussions. This unwavering reliability continues to cement its status as an indispensable tool in the toolkit of expert welders worldwide.

Previous:

Latest news

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025

-

Premium E316L Welding Rod for 316L Stainless SteelNewsAug.06,2025