Feb . 01, 2025 02:23

Back to list

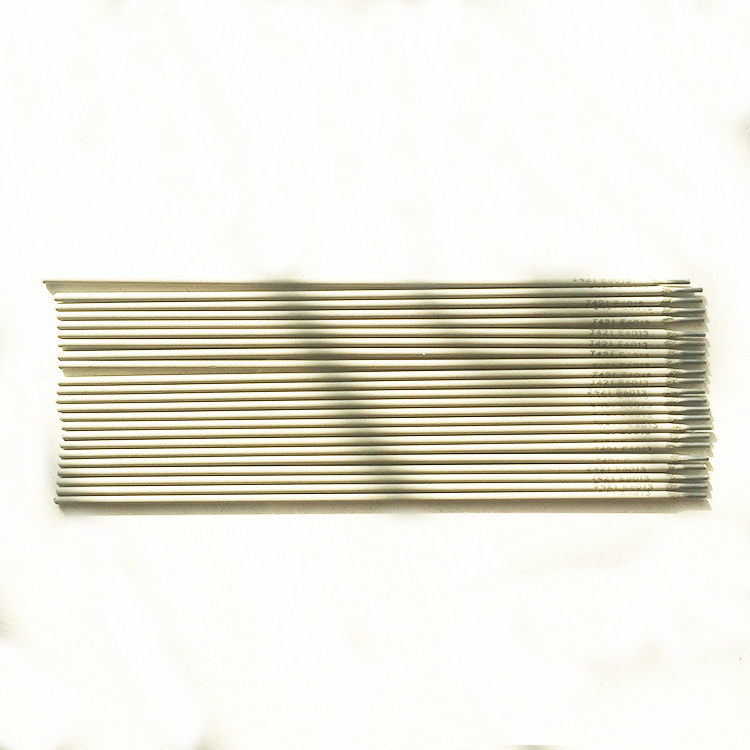

1/8 welding rod 7018

The 1/8 welding rod 7018 is a prime choice for welders who prioritize precision, reliability, and professional-grade outcomes. As one of the most commonly used rods in the welding industry, the 7018 stands out for its versatility and efficiency, highly recommended for those working on mild steel and low-alloy steel jobs. This article delves into the key attributes and advantages of the 1/8 welding rod 7018, grounding our insights in real-world experience and technical expertise.

In leveraging the expertise surrounding the 7018 welding rod, one must consider the importance of proper storage and handling. As a low-hydrogen electrode, it is vital to keep the rods dry and free from contaminants. Ensuring the welding rods are kept in a rod oven when not in immediate use prevents moisture absorption, protecting the integrity of the welds. Negligence in this area can lead to hydrogen-induced cracking, undermining the reliability of the weld and the overall project. Authoritative sources in the welding community often emphasize the rod's compatibility with AC and DC+ currents, offering versatility across different power sources and welding machines. This adaptability proves valuable for practitioners in fieldwork or varying job sites where equipment availability may differ. Having a welding rod that can perform effectively under different electrical settings positions professionals to tackle a wider array of tasks confidently and efficiently. For those seeking trustworthiness in their welding supplies, 7018 rods manufactured under internationally recognized standards offer additional peace of mind. Certifications ensure that the rods meet rigorous industry requirements, confirming both their performance and compliance with safety regulations. In conclusion, the 1/8 welding rod 7018 is an exemplary tool that blends precision, strength, and usability. Its attributes, from arc stability to tensile strength, make it indispensable for welders aiming to achieve professional-grade results across various applications. By understanding its benefits and adhering meticulously to its handling requirements, welders can leverage the full potential of the 7018 rod, attesting to its status as a cornerstone in welding expertise and excellence.

In leveraging the expertise surrounding the 7018 welding rod, one must consider the importance of proper storage and handling. As a low-hydrogen electrode, it is vital to keep the rods dry and free from contaminants. Ensuring the welding rods are kept in a rod oven when not in immediate use prevents moisture absorption, protecting the integrity of the welds. Negligence in this area can lead to hydrogen-induced cracking, undermining the reliability of the weld and the overall project. Authoritative sources in the welding community often emphasize the rod's compatibility with AC and DC+ currents, offering versatility across different power sources and welding machines. This adaptability proves valuable for practitioners in fieldwork or varying job sites where equipment availability may differ. Having a welding rod that can perform effectively under different electrical settings positions professionals to tackle a wider array of tasks confidently and efficiently. For those seeking trustworthiness in their welding supplies, 7018 rods manufactured under internationally recognized standards offer additional peace of mind. Certifications ensure that the rods meet rigorous industry requirements, confirming both their performance and compliance with safety regulations. In conclusion, the 1/8 welding rod 7018 is an exemplary tool that blends precision, strength, and usability. Its attributes, from arc stability to tensile strength, make it indispensable for welders aiming to achieve professional-grade results across various applications. By understanding its benefits and adhering meticulously to its handling requirements, welders can leverage the full potential of the 7018 rod, attesting to its status as a cornerstone in welding expertise and excellence.

Previous:

Latest news

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025

-

Premium E316L Welding Rod for 316L Stainless SteelNewsAug.06,2025