Jun . 28, 2024 05:10

Back to list

316L Stainless Steel Welding Rod Wholesale Manufacturer

Understanding the Significance of Wholesale 316L Welding Rods from Reputed Manufacturers

In the world of industrial manufacturing and fabrication, the choice of welding materials plays a pivotal role in determining the quality and durability of the final product. One such essential element is the 316L welding rod, a material that has gained significant traction due to its exceptional properties. As a wholesale 316L welding rod manufacturer, understanding the importance of these rods and the impact they have on various industries is crucial.

316L stainless steel, an alloy known for its high corrosion resistance, particularly against chloride-induced stress corrosion cracking, is widely used in applications where exposure to harsh environments is inevitable. The 'L' in 316L indicates a lower carbon content, which further enhances its weldability and reduces the risk of intergranular corrosion. This makes 316L welding rods ideal for industries like marine engineering, chemical processing, and even food and pharmaceutical equipment manufacturing.

Wholesale 316L welding rod manufacturers cater to a diverse range of customers, from small-scale fabricators to large-scale industrial corporations. By offering these rods at a wholesale rate, they ensure cost-effectiveness without compromising on quality. The scale of production allows manufacturers to leverage economies of scale, reducing unit costs while maintaining stringent quality control measures.

The manufacturing process of 316L welding rods involves multiple stages, starting with the selection of premium raw materials. High-quality 316L stainless steel is melted, cast into billets, and then cold-drawn to the desired diameter. This is followed by heat treatment and strict quality inspections to guarantee consistency and reliability This is followed by heat treatment and strict quality inspections to guarantee consistency and reliability This is followed by heat treatment and strict quality inspections to guarantee consistency and reliability This is followed by heat treatment and strict quality inspections to guarantee consistency and reliability

This is followed by heat treatment and strict quality inspections to guarantee consistency and reliability This is followed by heat treatment and strict quality inspections to guarantee consistency and reliability wholesale 316l welding rod manufacturer. The end result is a welding rod that delivers superior performance, excellent fusion characteristics, and strong mechanical properties.

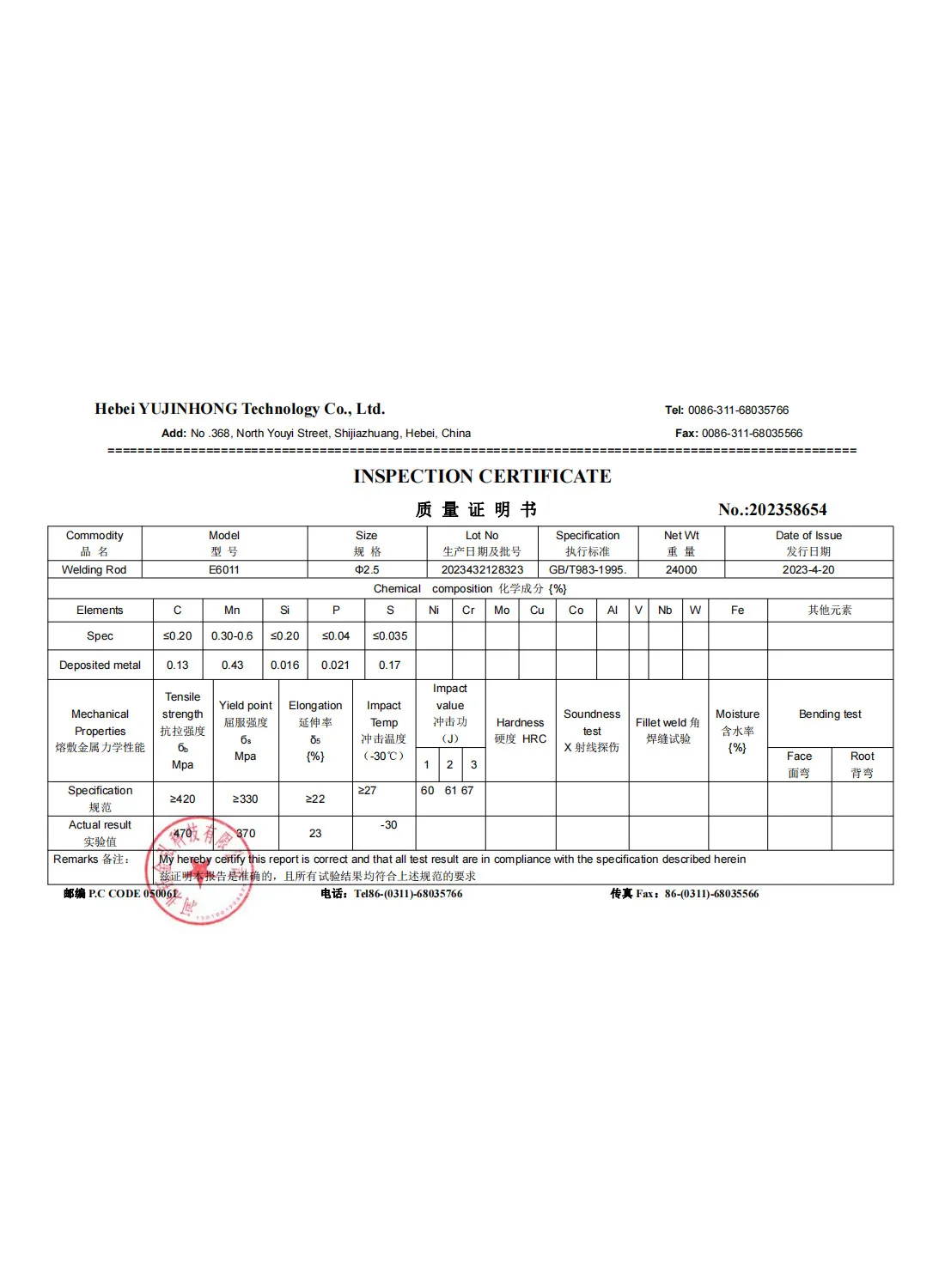

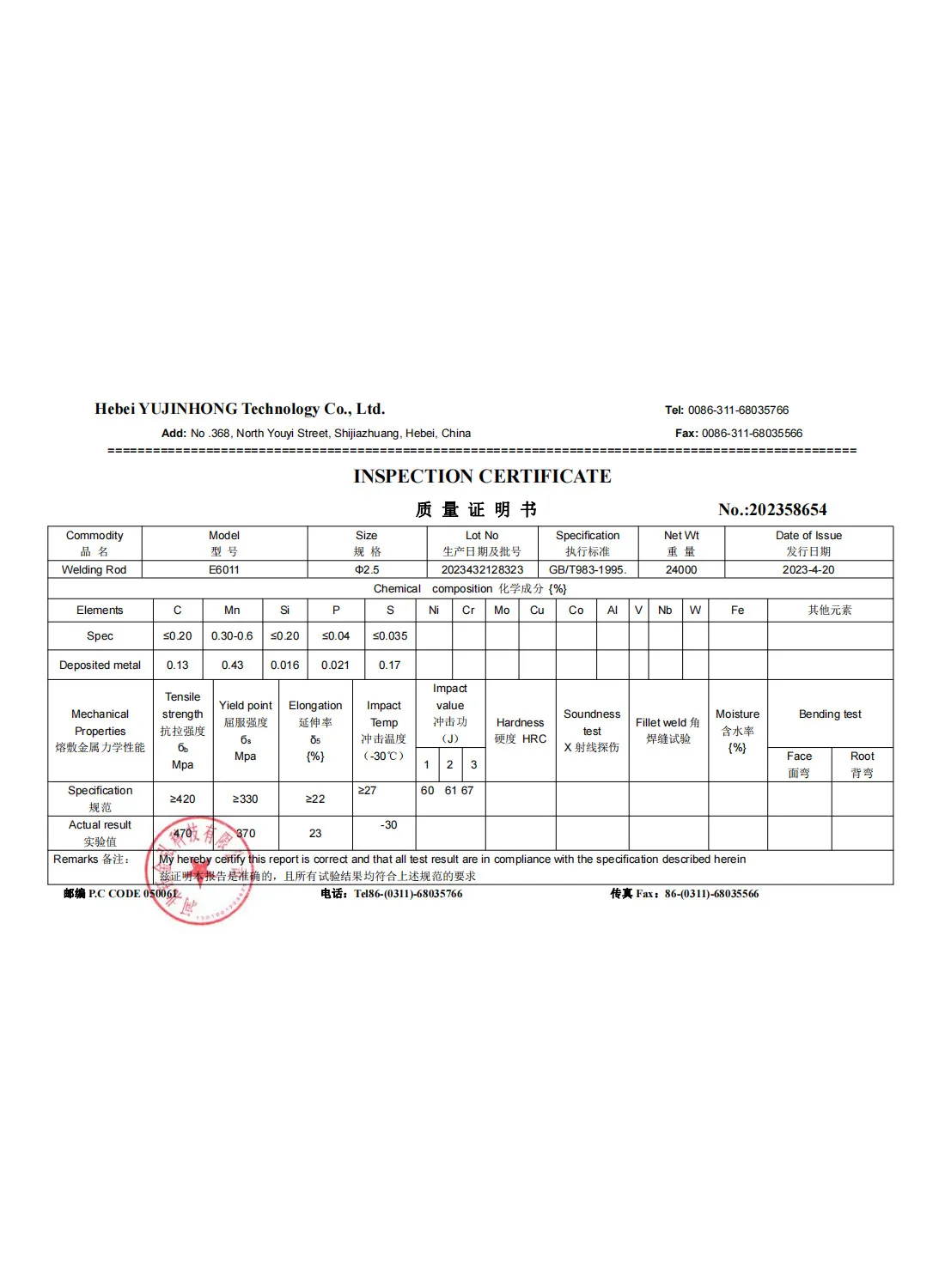

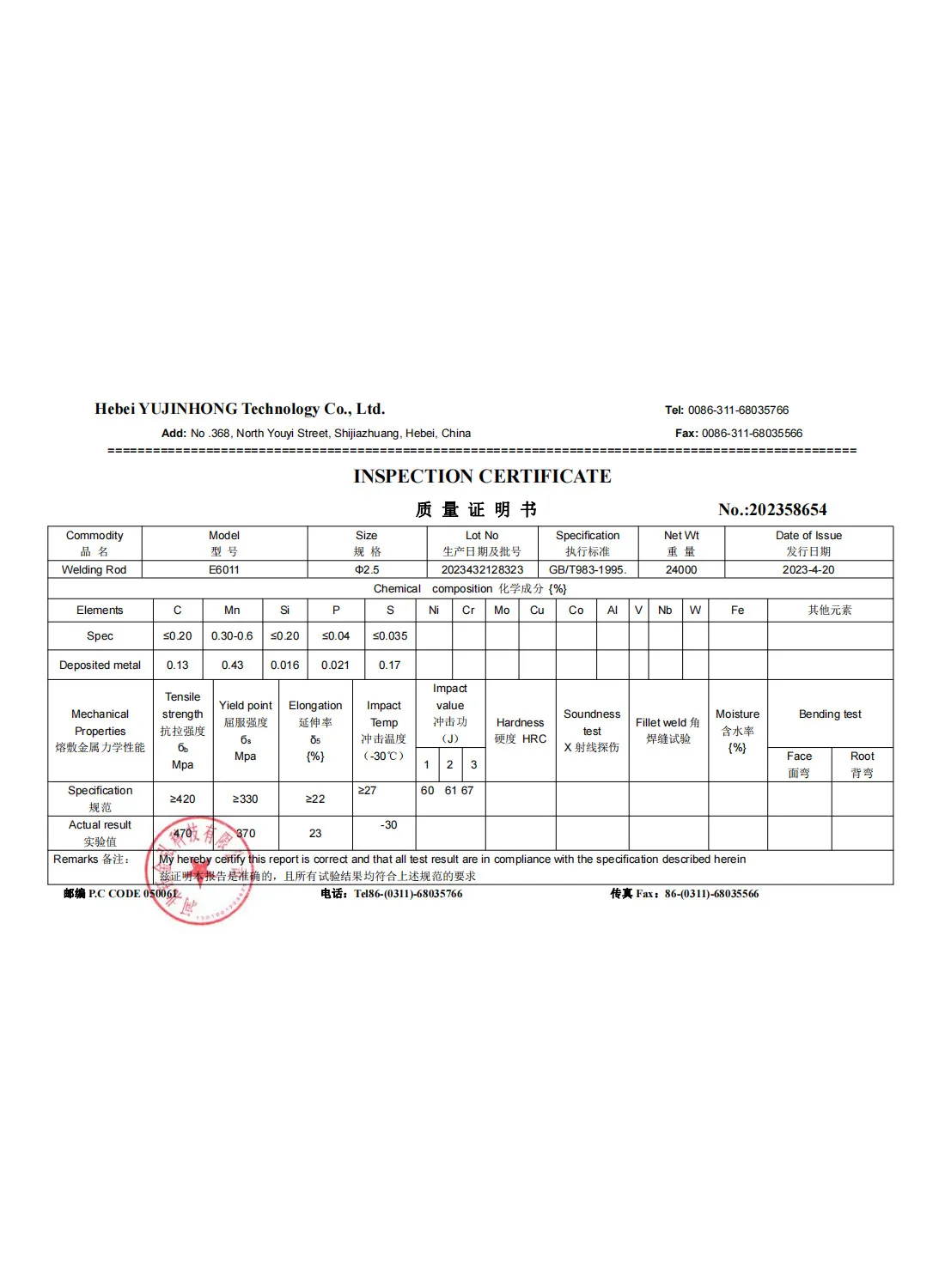

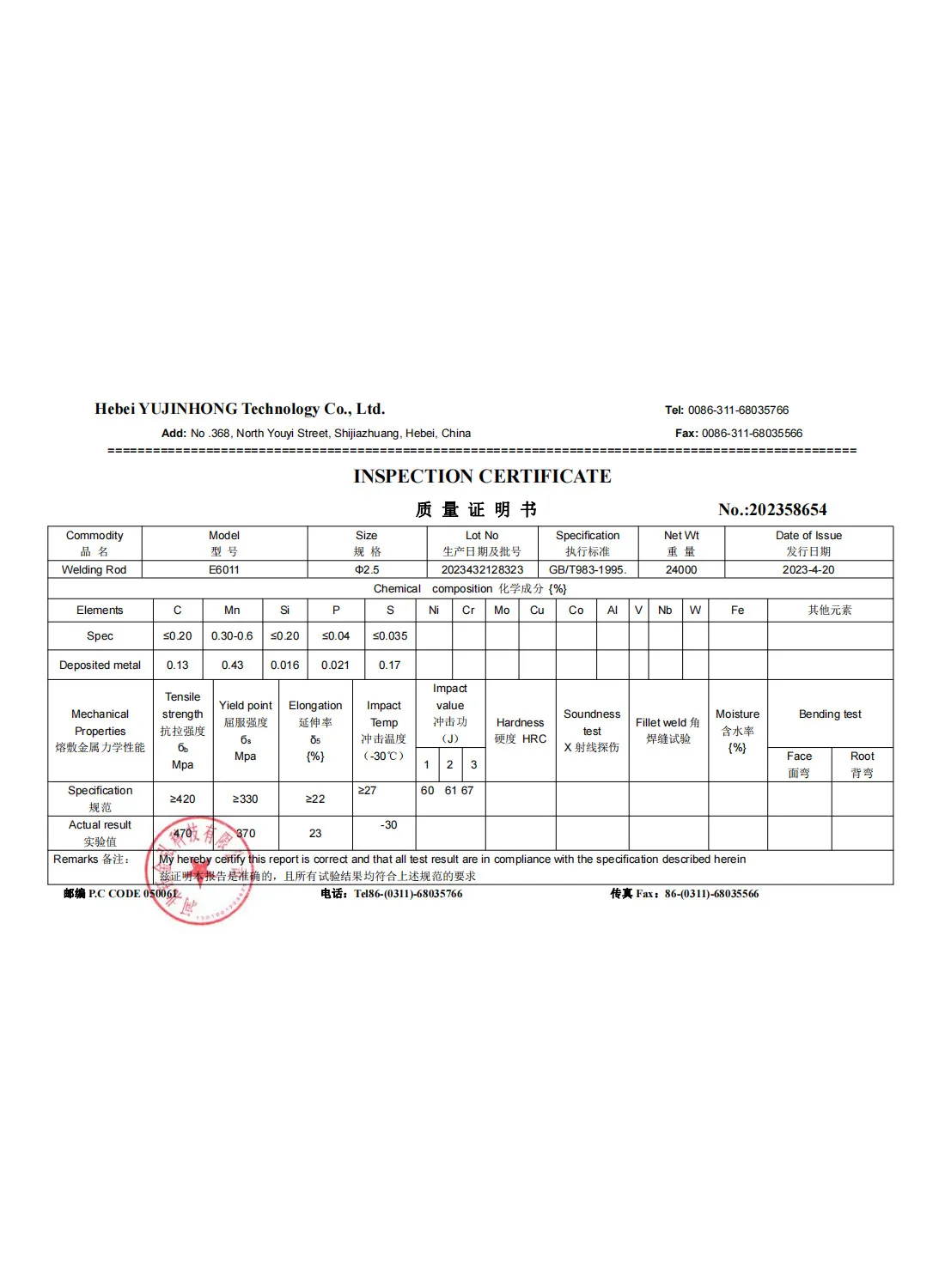

When it comes to choosing a wholesale 316L welding rod manufacturer, several factors must be considered. A reliable manufacturer should have a proven track record of producing consistent, high-quality products, backed by certifications like ISO, AWS, or ASME. They should also offer a wide range of diameters and lengths to accommodate different welding applications. Additionally, strong customer service, prompt delivery, and competitive pricing are key aspects that contribute to a successful business partnership.

In conclusion, the significance of wholesale 316L welding rods from reputable manufacturers cannot be overstated. These rods not only ensure top-notch performance in demanding environments but also provide cost savings and operational efficiency to businesses. As global demand for corrosion-resistant materials continues to rise, the role of these manufacturers becomes even more vital in meeting the needs of various industries. By prioritizing quality, versatility, and customer satisfaction, they pave the way for sustainable and efficient welding solutions.

wholesale 316l welding rod manufacturer. The end result is a welding rod that delivers superior performance, excellent fusion characteristics, and strong mechanical properties.

When it comes to choosing a wholesale 316L welding rod manufacturer, several factors must be considered. A reliable manufacturer should have a proven track record of producing consistent, high-quality products, backed by certifications like ISO, AWS, or ASME. They should also offer a wide range of diameters and lengths to accommodate different welding applications. Additionally, strong customer service, prompt delivery, and competitive pricing are key aspects that contribute to a successful business partnership.

In conclusion, the significance of wholesale 316L welding rods from reputable manufacturers cannot be overstated. These rods not only ensure top-notch performance in demanding environments but also provide cost savings and operational efficiency to businesses. As global demand for corrosion-resistant materials continues to rise, the role of these manufacturers becomes even more vital in meeting the needs of various industries. By prioritizing quality, versatility, and customer satisfaction, they pave the way for sustainable and efficient welding solutions.

This is followed by heat treatment and strict quality inspections to guarantee consistency and reliability This is followed by heat treatment and strict quality inspections to guarantee consistency and reliability

This is followed by heat treatment and strict quality inspections to guarantee consistency and reliability This is followed by heat treatment and strict quality inspections to guarantee consistency and reliability wholesale 316l welding rod manufacturer. The end result is a welding rod that delivers superior performance, excellent fusion characteristics, and strong mechanical properties.

When it comes to choosing a wholesale 316L welding rod manufacturer, several factors must be considered. A reliable manufacturer should have a proven track record of producing consistent, high-quality products, backed by certifications like ISO, AWS, or ASME. They should also offer a wide range of diameters and lengths to accommodate different welding applications. Additionally, strong customer service, prompt delivery, and competitive pricing are key aspects that contribute to a successful business partnership.

In conclusion, the significance of wholesale 316L welding rods from reputable manufacturers cannot be overstated. These rods not only ensure top-notch performance in demanding environments but also provide cost savings and operational efficiency to businesses. As global demand for corrosion-resistant materials continues to rise, the role of these manufacturers becomes even more vital in meeting the needs of various industries. By prioritizing quality, versatility, and customer satisfaction, they pave the way for sustainable and efficient welding solutions.

wholesale 316l welding rod manufacturer. The end result is a welding rod that delivers superior performance, excellent fusion characteristics, and strong mechanical properties.

When it comes to choosing a wholesale 316L welding rod manufacturer, several factors must be considered. A reliable manufacturer should have a proven track record of producing consistent, high-quality products, backed by certifications like ISO, AWS, or ASME. They should also offer a wide range of diameters and lengths to accommodate different welding applications. Additionally, strong customer service, prompt delivery, and competitive pricing are key aspects that contribute to a successful business partnership.

In conclusion, the significance of wholesale 316L welding rods from reputable manufacturers cannot be overstated. These rods not only ensure top-notch performance in demanding environments but also provide cost savings and operational efficiency to businesses. As global demand for corrosion-resistant materials continues to rise, the role of these manufacturers becomes even more vital in meeting the needs of various industries. By prioritizing quality, versatility, and customer satisfaction, they pave the way for sustainable and efficient welding solutions. Latest news

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025

-

Premium E316L Welding Rod for 316L Stainless SteelNewsAug.06,2025