Jan . 25, 2025 05:32

Back to list

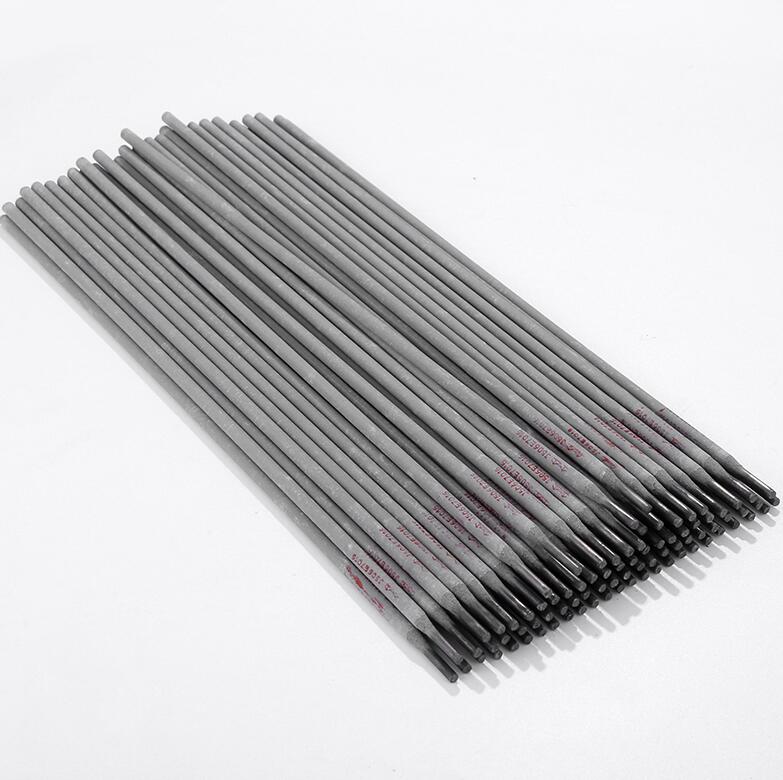

Factory supply 7018 Welding Rods Electrodes

Welding is an essential process in many industries, ranging from construction to manufacturing, where the integrity of metal joints is crucial. Among the various welding rods available, the 7018 5/32-inch welding rods stand out due to their unique properties and applications. These rods are specifically designed to deliver high-quality welds, making them a trusted choice for professionals worldwide.

In terms of expertise, mastering the use of 7018 5/32 welding rods involves understanding the correct amperage settings and welding techniques. These rods are generally used with a Direct Current Electrode Positive (DCEP) setting, which enhances penetration and ensures a stable arc. The recommended amperage range for 5/32 rods typically falls between 110 to 165 amps, depending on the thickness of the material and the welding position. Authoritativeness in the use of 7018 5/32 welding rods comes from recognizing their versatility across different welding scenarios. They are suitable for all positions—flat, horizontal, vertical, and overhead—making them a go-to choice for structural steel, pipelines, and heavy machinery repairs. For welders participating in projects that demand rigorous standards, such as those adhering to American Welding Society (AWS) specifications, utilizing 7018 rods ensures compliance with industry expectations. Trust in 7018 5/32 welding rods is solidified through consistent results and endorsements from industry professionals. These rods have a proven track record of delivering reliable and long-lasting welds, which is why they are the electrode of choice in critical infrastructure projects. Clients and project managers can rely on the quality and durability of welds produced by experienced operators using these rods, ensuring that safety and performance standards are met. In practical applications, the benefits of using 7018 5/32 welding rods extend beyond just technical specifications. They contribute to cost-effective welding operations by reducing the likelihood of rework due to weld failures. Furthermore, the aesthetic quality of the welds they produce is superior, which can be crucial in visible joint applications where appearance matters alongside strength. In conclusion, 7018 5/32 welding rods offer a combination of low hydrogen content, versatility, and performance that makes them indispensable to the skilled welder’s toolkit. By understanding their properties, applications, and handling requirements, welders can maximize the potential of these rods, delivering work that meets the highest standards of quality and safety. Whether for structural steelwork, repair tasks, or complex fabrication, 7018 rods stand as a benchmark for excellence in the welding world.

In terms of expertise, mastering the use of 7018 5/32 welding rods involves understanding the correct amperage settings and welding techniques. These rods are generally used with a Direct Current Electrode Positive (DCEP) setting, which enhances penetration and ensures a stable arc. The recommended amperage range for 5/32 rods typically falls between 110 to 165 amps, depending on the thickness of the material and the welding position. Authoritativeness in the use of 7018 5/32 welding rods comes from recognizing their versatility across different welding scenarios. They are suitable for all positions—flat, horizontal, vertical, and overhead—making them a go-to choice for structural steel, pipelines, and heavy machinery repairs. For welders participating in projects that demand rigorous standards, such as those adhering to American Welding Society (AWS) specifications, utilizing 7018 rods ensures compliance with industry expectations. Trust in 7018 5/32 welding rods is solidified through consistent results and endorsements from industry professionals. These rods have a proven track record of delivering reliable and long-lasting welds, which is why they are the electrode of choice in critical infrastructure projects. Clients and project managers can rely on the quality and durability of welds produced by experienced operators using these rods, ensuring that safety and performance standards are met. In practical applications, the benefits of using 7018 5/32 welding rods extend beyond just technical specifications. They contribute to cost-effective welding operations by reducing the likelihood of rework due to weld failures. Furthermore, the aesthetic quality of the welds they produce is superior, which can be crucial in visible joint applications where appearance matters alongside strength. In conclusion, 7018 5/32 welding rods offer a combination of low hydrogen content, versatility, and performance that makes them indispensable to the skilled welder’s toolkit. By understanding their properties, applications, and handling requirements, welders can maximize the potential of these rods, delivering work that meets the highest standards of quality and safety. Whether for structural steelwork, repair tasks, or complex fabrication, 7018 rods stand as a benchmark for excellence in the welding world.

Latest news

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025

-

Premium E316L Welding Rod for 316L Stainless SteelNewsAug.06,2025