Jan . 25, 2025 05:54

Back to list

Cellulose vertical downward Welding Electrode E6011

For welders around the globe, the question of choosing the right electrode is both a science and an art, blending technical specifications with hands-on expertise. Among the most frequently discussed electrodes, the 7018 and 6011 are at the forefront due to their reliability and performance across a variety of welding applications. Delving into their unique characteristics can guide professionals and hobbyists in making informed decisions that enhance project quality and efficiency.

Industry consensus underscores the necessity of choosing the right electrode tailored to specific job requirements. The 7018 is synonymous with strength and aesthetic finish in ideal conditions, whereas the 6011 represents resilience and adaptability in challenging environments. Welding experts stress the acquisition of skill through practice and an understanding of material compatibilities as cornerstones of successful welding with these electrodes. Ultimately, the choice between the 7018 and 6011 should be informed by project specifications, taking into account factors such as material thickness, surface condition, and welding position. Both electrodes have established themselves as authoritative standards in their respective domains, each offering distinct advantages that cater to a wide range of welding demands. Welders who master the intricacies of these electrodes are positioned not only to enhance their craftsmanship but also to contribute significantly to the safety and durability of the structures they build. With evolving welding technologies and materials, ongoing education and adaptation are vital. As seasoned practitioners continue to share their insights and develop new techniques, the wealth of shared knowledge enriches the welding community, ensuring that both seasoned welders and newcomers alike can achieve excellence in their craft.

Industry consensus underscores the necessity of choosing the right electrode tailored to specific job requirements. The 7018 is synonymous with strength and aesthetic finish in ideal conditions, whereas the 6011 represents resilience and adaptability in challenging environments. Welding experts stress the acquisition of skill through practice and an understanding of material compatibilities as cornerstones of successful welding with these electrodes. Ultimately, the choice between the 7018 and 6011 should be informed by project specifications, taking into account factors such as material thickness, surface condition, and welding position. Both electrodes have established themselves as authoritative standards in their respective domains, each offering distinct advantages that cater to a wide range of welding demands. Welders who master the intricacies of these electrodes are positioned not only to enhance their craftsmanship but also to contribute significantly to the safety and durability of the structures they build. With evolving welding technologies and materials, ongoing education and adaptation are vital. As seasoned practitioners continue to share their insights and develop new techniques, the wealth of shared knowledge enriches the welding community, ensuring that both seasoned welders and newcomers alike can achieve excellence in their craft.

Latest news

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

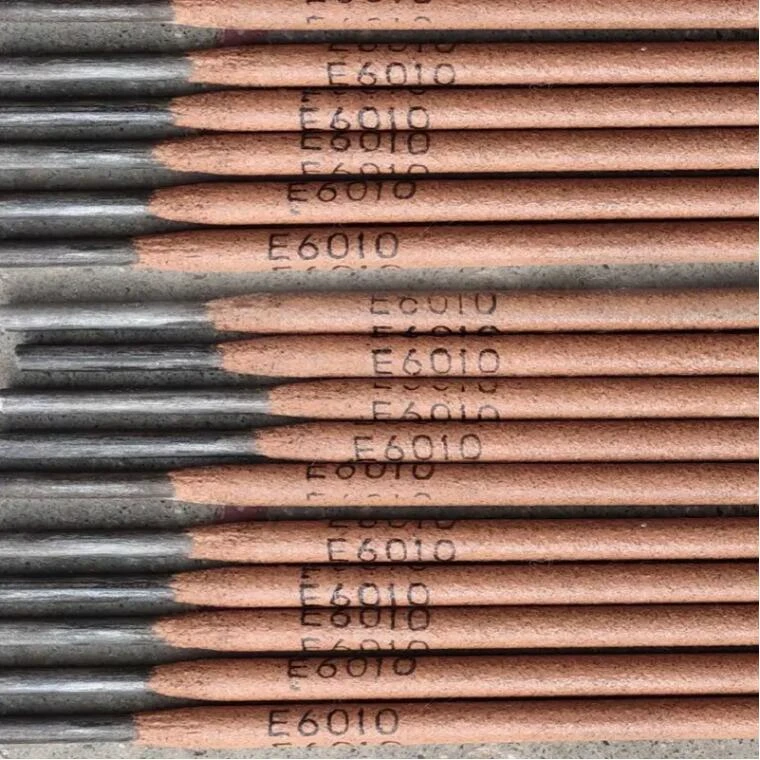

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025

-

Premium E316L Welding Rod for 316L Stainless SteelNewsAug.06,2025