Jan . 25, 2025 23:54

Back to list

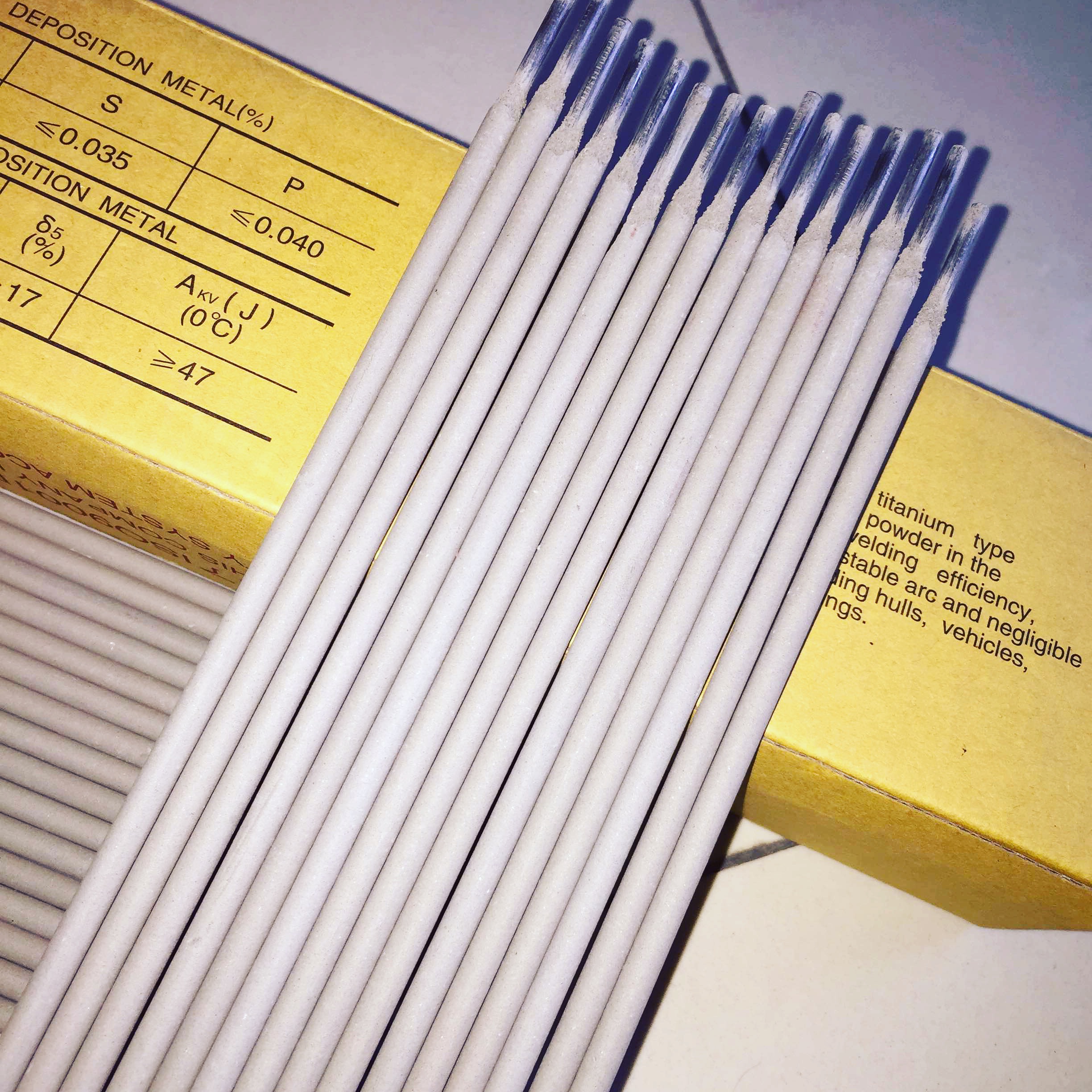

aws e6013 welding electrodes

Arc welding electrodes play a crucial role in the welding process, serving as the medium through which the welding current passes to produce an electric arc. This arc generates the necessary heat to melt and join metals, making the choice of electrode paramount to achieving optimal results. Understanding the intricacies of arc welding electrodes requires experience, expertise, authoritativeness, and trustworthiness—characteristics that define industry professionals who have spent years honing their craft.

The authoritativeness associated with arc welding electrodes emerges from industry standards and compliance elements that guide usage across different sectors. As an authoritative figure ensures that adherence to standards like the American Welding Society (AWS) codifications is non-negotiable, guaranteeing not only performance but also safety in all welding operations. Trustworthiness, a foundational pillar in welding practice, is inherently linked to the brand's reputation and quality of electrodes. Reputable manufacturers provide comprehensive data sheets delineating mechanical properties, recommended use, and storage conditions. Such transparency builds trust among professionals, ensuring reliable outcomes and consistency across projects. Welding veterans often prefer brands that uphold these principles, providing a safety net against substandard performance. Practical experiences shared by proficient welders highlight the significance of electrode diameter in relation to the thickness of the workpiece. Selecting the correct diameter—ranging from 1/16 inch for thin metals to 5/32 inch for thicker ones—takes meticulous judgment, often nurtured through years of hands-on experience. Furthermore, the storage and handling of electrodes have a profound impact on weld quality. Moisture absorption can lead to hydrogen entrapment, resulting in weld defects such as cracking. Seasoned practitioners advocate for proper storage solutions, such as dry rod ovens and sealed packages, particularly in humid environments. In conclusion, the domain of arc welding electrodes is multi-faceted, intersecting technical knowledge, hands-on experience, authoritative standards, and trustworthiness. As welders navigate projects, discerning the right electrode not only optimizes performance but elevates the overall integrity of structures. Those who master these elements are well-regarded in the industry, continuously setting benchmarks for quality and safety in welding practices.

The authoritativeness associated with arc welding electrodes emerges from industry standards and compliance elements that guide usage across different sectors. As an authoritative figure ensures that adherence to standards like the American Welding Society (AWS) codifications is non-negotiable, guaranteeing not only performance but also safety in all welding operations. Trustworthiness, a foundational pillar in welding practice, is inherently linked to the brand's reputation and quality of electrodes. Reputable manufacturers provide comprehensive data sheets delineating mechanical properties, recommended use, and storage conditions. Such transparency builds trust among professionals, ensuring reliable outcomes and consistency across projects. Welding veterans often prefer brands that uphold these principles, providing a safety net against substandard performance. Practical experiences shared by proficient welders highlight the significance of electrode diameter in relation to the thickness of the workpiece. Selecting the correct diameter—ranging from 1/16 inch for thin metals to 5/32 inch for thicker ones—takes meticulous judgment, often nurtured through years of hands-on experience. Furthermore, the storage and handling of electrodes have a profound impact on weld quality. Moisture absorption can lead to hydrogen entrapment, resulting in weld defects such as cracking. Seasoned practitioners advocate for proper storage solutions, such as dry rod ovens and sealed packages, particularly in humid environments. In conclusion, the domain of arc welding electrodes is multi-faceted, intersecting technical knowledge, hands-on experience, authoritative standards, and trustworthiness. As welders navigate projects, discerning the right electrode not only optimizes performance but elevates the overall integrity of structures. Those who master these elements are well-regarded in the industry, continuously setting benchmarks for quality and safety in welding practices.

Previous:

Latest news

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025

-

Premium E316L Welding Rod for 316L Stainless SteelNewsAug.06,2025