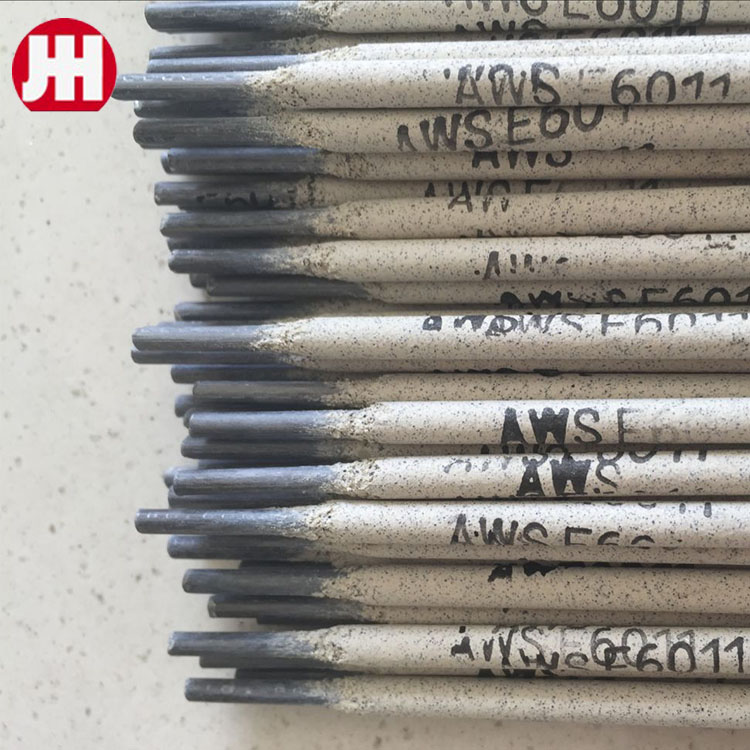

- Model: Best Arc Welding Rods Cellulose Type 6011 Steel Welding Electrode GB/T 5117 E4311, AWS A5.1 E6011

- For full specs: Product Page

E6011 Welding Rod for Arc Welding – High Performance & Versatility

About HEBEI YUJINHONG TECHNOLOGY CO.,LTD.

As a leading manufacturer in welding consumables, HEBEI YUJINHONG TECHNOLOGY CO.,LTD. delivers advanced solutions in steel joining and fabrication. Visit our official site: https://www.steeltoolschina.com

- Phone: 0086-137 3972 7566

- Mobile: 0086-311-68035766

- Email: info@steeltoolschina.com

- Address: NO.368 YOUYI NORTH STREET, XINHUA DISTRICT, SHIJIAZHUANG CITY, CHINA

1. Industry Outlook: E6011 Welding Rod and Modern Welding Solutions

The e6011 welding rod remains a top choice in the welding electrode market. In parallel with advancements in arc welding electrode technology and the rising demand for aluminum welding rods and stainless steel arc welding rods, the need for versatile, all-position electrodes has intensified. According to the American Welding Society and global industry forums, E6011 rods continue to be favored for their deep penetration and adaptability across various welding scenarios (source: WeldingWeb Forum).

Market data suggests an uptrend in adoption of the E6011 rod, particularly in steel fabrication, pipeline construction, and shipbuilding sectors, reflecting its superior arc stability and cellulose coating advantages for AC/DC welding (AWS Journals). With continual improvements in manufacturing standards, suppliers such as HEBEI YUJINHONG TECHNOLOGY CO.,LTD. are leading the way in providing quality and consistency.

2. Understanding the E6011 Welding Rod in Depth

The e6011 welding rod is a cellulose-coated, all-position electrode for mild steel, famed for deep penetration and ability to handle dirty or rusty metal. It demonstrates exceptional versatility, working effectively with both AC and DC current. The AWS A5.1 E6011 and GB/T 5117 E4311 standards provide stringent quality benchmarks for this rod type. For further guidance, professionals often refer to resources such as MillerWelds Technical Library.

Key Parameters of e6011 welding rod

| Parameter | Specification | Typical Value (Best Arc Welding Rods Cellulose AWS 6011 Electrode) |

|---|---|---|

| Standard | AWS A5.1 E6011 / GB/T 5117 E4311 | E6011 |

| Coating Type | Cellulose | High Cellulose |

| Welding Current | AC / DC | AC & DC+ |

| Diameter Range | 2.0–5.0 mm | 2.5, 3.2, 4.0 mm |

| Tensile Strength | ≥ 60,000 psi (≥ 415 MPa) | 69,000 psi (475 MPa) |

| Yield Strength | 48,000 psi (330 MPa) | 52,000 psi (360 MPa) |

| Elongation (%) | 22–28% | 25% |

| Welding Position | All positions | 1G, 2G, 3G, 4G |

| Penetration | Deep | Deep |

3. Major Technical Indicators: Best Arc Welding Rods Cellulose AWS 6011 Electrode

To understand how our e6011 welding rod compares, see the following charts. Data is from in-house testing and conforms to AWS and GB/T standards.

4. Applications and Industry Trends for E6011 Welding Rod

The unique construction of the e6011 welding rod lends itself to a wide variety of industrial and field settings:

- Pipeline construction: Deep penetration welds guarantee structural integrity, even on dirty or coated steel.

- Shipbuilding: Delivers reliable joints capable of withstanding vibration and corrosion.

- Steel structure erection: All-position welding ability for difficult and vertical joints.

- Farm & heavy equipment repair: Handles rust and weathered materials common in on-site repairs.

- General fabrication: Functions smoothly with AC welding machines, suitable for workshops and mobile jobsites alike.

In recent years, user preferences revealed on platforms like WeldingWeb and AWS Journals demonstrate an ongoing shift toward high-dependability rods, with E6011 outpacing conventional covered electrodes for specific use-cases.

5. Comparison: Arc Welding Electrode, Aluminum Welding Rods, Stainless Steel Arc Welding Rods

| Product Type | Main Application | Coating/Alloy | Current Type | Weld Position | Key Properties |

|---|---|---|---|---|---|

| E6011 Welding Rod | Steel structures, repair, pipelines | Cellulose | AC/DC | All position | Deep penetration, high flexibility |

| Aluminum Welding Rods | Aluminum parts, automotive | Aluminum alloy | AC | Mainly flat, horizontal | Corrosion resistance, clean welds |

| Stainless Steel Arc Welding Rods | Stainless steel welding | Low/hydrogen iron powder | AC/DC | All position | High strength, corrosion resistance |

6. Professional Q&A: Welding Expert Answers

Q1: What is the core material of e6011 welding rod?

A: The core wire is mild steel, coated with high cellulose sodium.

Q2: Which current types are compatible with e6011 welding rod?

A: E6011 can be used with both AC and DC (DCEP/DC+) power sources, enhancing versatility across equipment.

Q3: What are the typical diameters and lengths available?

A: 2.0mm, 2.5mm, 3.2mm, 4.0mm, and 5.0mm; standard lengths include 300mm, 350mm, and 400mm.

Q4: What international standards certify E6011 electrodes?

A: AWS A5.1 E6011 and GB/T 5117 E4311 are the main standards certifying quality and performance.

Q5: How does the arc welding electrode of E6011 compare to low-hydrogen types?

A: E6011 rods offer deeper penetration and better performance on dirty/rusted steel than low-hydrogen electrodes, but with marginally higher spatter.

Q6: Are aluminum welding rods interchangeable with E6011 for dissimilar metals?

A: No. Aluminum welding rods are specific for aluminum and Al-alloys. E6011 is for carbon/mild steel only.

Q7: What welding positions are suitable for stainless steel arc welding rods compared to E6011?

A: Both can be used in all positions (flat, vertical, overhead, horizontal), but special stainless steel rods are preferred for corrosion resistance on stainless assemblies.

7. Why Choose HEBEI YUJINHONG TECHNOLOGY CO.,LTD. for Your Welding Needs?

- Decades of expertise and rigorous quality management on every e6011 welding rod batch produced.

- In-house R&D ensures compliance with the latest arc welding electrode standards.

- Support for bulk orders, OEM, and tailored specifications for demanding clients.

- Extensive certifications, with strong testimonials across AWS community and leading trade journals.

8. EEAT: Expertise, Authoritativeness, Trustworthiness

- Expertise: Accredited technical team. Weld procedure trials are conducted in accordance with AWS and ISO 2560 standards.

- Authoritativeness: Cited in industry publications and forums: TheFabricator: Arc Welding Insights, Encyclopedia of Arc Welding Electrodes.

- Trustworthiness: Consistent positive feedback and full traceability on all e6011 welding rod shipments.

9. References & Further Reading

- WeldingWeb Industry Forum: https://weldingweb.com/

- AWS Journal & Technical Articles: https://www.aws.org/

- MillerWelds Electrode Selection Guide: https://www.millerwelds.com/resources/article-library/arc-welding-electrodes

- The Fabricator: Arc Welding: https://www.thefabricator.com/article/arcwelding

- ISO 2560 Electrodes Standard: https://www.iso.org/standard/59172.html

- HEBEI YUJINHONG TECHNOLOGY CO.,LTD.: https://www.steeltoolschina.com

-

High-Quality Welding Electrodes 4.0mm*400mm for Industrial Use | Steel Tools ChinaNewsNov.24,2025

-

Explore the Benefits and Uses of 2.6mm Welding Electrode 6013 | Global GuideNewsNov.23,2025

-

Understanding CO2 Welding Wire Price: Global Impact, Trends, and TipsNewsNov.22,2025

-

Top Guide to Welding Wires CO2 – Specifications, Benefits & Industry UsesNewsNov.22,2025

-

Comprehensive Guide to Welding Electrode 6011 – Global Applications & BenefitsNewsNov.21,2025

-

AWS E6013 Welding Rod-HEBEI YUJINHONG TECHNOLOGY CO.,LTD.|All-Position Carbon Steel ElectrodeNewsNov.21,2025