Premium Solid MIG Wire: Strong, Smooth Welds Every Time

The Crucial Role of solid mig wire in Modern Industrial Welding

In the vast landscape of modern manufacturing and construction, the integrity of welded joints is paramount. At the core of achieving robust, reliable welds lies the selection of high-quality filler materials. Among these, solid mig wire stands out as a fundamental component, widely adopted across diverse industries for its efficiency, versatility, and ability to produce high-strength welds. This comprehensive guide delves into the technical intricacies, application benefits, and strategic considerations for deploying premium solid mig wire in your operations, focusing on the specific attributes of Co2 Solid Welding Wire Solder Wire.

Our Co2 Solid Welding Wire Solder Wire, a prime example of high-performance mig solid welding wire, is engineered to meet the rigorous demands of various welding environments. It ensures superior arc stability, minimal spatter, and excellent bead appearance, contributing significantly to reduced post-weld cleanup and enhanced productivity. Understanding its manufacturing process, technical specifications, and application advantages is key to unlocking its full potential in your industrial applications.

Industry Trends and Market Dynamics for Welding Solid Wire

The global welding consumables market is experiencing consistent growth, driven by expansion in manufacturing, automotive, construction, and energy sectors. Within this, the demand for high-quality welding solid wire is particularly strong. Recent industry analyses project the global welding consumables market to reach approximately $15 billion by 2027, with a compound annual growth rate (CAGR) of around 4.5% from 2022. This growth is largely fueled by technological advancements, increasing automation in welding processes, and a heightened focus on weld quality and efficiency.

- Automation & Robotics: The proliferation of robotic welding systems necessitates consistent, high-quality mig solid welding wire for uninterrupted operation and repeatable results.

- Sustainable Manufacturing: There's a growing emphasis on consumables that reduce spatter and fumes, contributing to cleaner work environments and less material waste, aligning with eco-friendly manufacturing initiatives.

- High-Strength Alloys: The development of advanced high-strength steels and alloys in sectors like automotive and aerospace demands specialized solid mig wire capable of matching or exceeding base material properties.

- Digitalization: Integration of smart welding systems and data analytics for process optimization and quality control is driving demand for wire with consistent metallurgical and dimensional properties.

Manufacturers are continuously innovating to produce welding solid wire with improved arc characteristics, higher deposition rates, and enhanced mechanical properties. This evolution ensures that industries can achieve stronger, more reliable, and cost-effective welds.

Manufacturing Process of Co2 Solid Welding Wire Solder Wire

The production of high-quality solid mig wire is a meticulously controlled process, beginning with the selection of premium raw materials and culminating in stringent quality assurance. Our Co2 Solid Welding Wire Solder Wire undergoes the following detailed manufacturing stages:

1. Raw Material Selection & Preparation

The process starts with high-purity steel rods (typically low carbon steel), selected based on their precise chemical composition, often containing deoxidizers like silicon and manganese. These elements are crucial for scavenging oxygen during welding, preventing porosity, and enhancing weld strength. Incoming rods are thoroughly inspected for defects and surface impurities.

2. Descaling & Cleaning

The steel rods undergo mechanical descaling (e.g., shot blasting) to remove scale and rust, followed by chemical cleaning (acid pickling) to eliminate residual oxides and surface contaminants. This ensures a perfectly clean surface for subsequent drawing operations and prevents the introduction of impurities into the weld pool.

3. Wire Drawing

The cleaned rods are progressively drawn through a series of dies, gradually reducing their diameter to the desired final gauge. This cold working process not only shapes the wire but also refines its grain structure, significantly improving its tensile strength and ductility. Lubricants are critical during drawing to minimize friction and prevent overheating, ensuring a smooth surface finish and consistent wire diameter.

4. Copper Coating

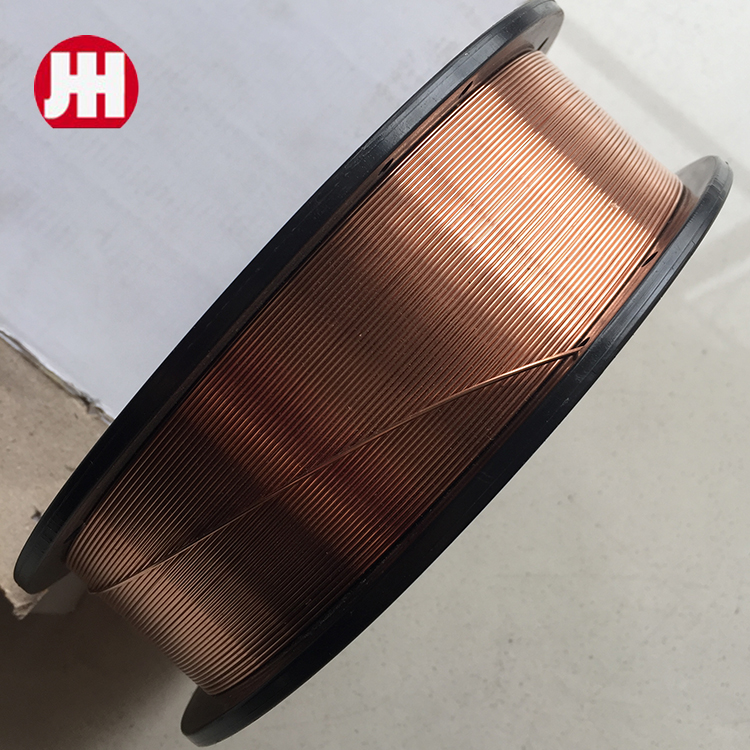

A thin, uniform layer of copper is electroplated onto the drawn wire. This copper coating serves multiple critical functions: it improves electrical conductivity for consistent arc starting and stability, enhances current transfer, and provides corrosion resistance during storage. Furthermore, it acts as an additional lubricant, facilitating smooth wire feeding through the welding gun.

5. Spooling & Packaging

The finished copper-coated wire is precision wound onto spools of various sizes (e.g., 5kg, 15kg, 20kg). Precision layering is essential to prevent tangling and ensure smooth feeding during welding. The spools are then carefully packaged to protect the wire from moisture and contamination during transit and storage.

6. Quality Control & Testing Standards

Throughout the entire manufacturing process, rigorous quality control measures are implemented. Our mig solid welding wire adheres strictly to international testing standards such as ISO 9001 for quality management systems, AWS (American Welding Society) specifications (e.g., AWS A5.18/A5.18M ER70S-6 for carbon steel wires), and relevant ANSI standards. Key tests include:

- Chemical Analysis: Verification of raw material and finished wire composition.

- Mechanical Testing: Tensile strength, yield strength, elongation, and impact toughness of weld metal.

- Dimensional Accuracy: Consistent wire diameter and spooling quality.

- Coating Thickness & Adhesion: Ensuring uniform and durable copper coating.

- Weldability Tests: Actual welding trials to assess arc stability, spatter levels, and bead appearance.

These comprehensive tests guarantee that our Co2 Solid Welding Wire Solder Wire delivers exceptional performance and a long service life under demanding industrial conditions, offering superior corrosion resistance and energy-saving benefits through efficient deposition.

Technical Specifications and Chemical Composition

Understanding the precise technical specifications of solid mig wire is crucial for engineers and procurement specialists to ensure optimal weld quality and compliance with project requirements. Our Co2 Solid Welding Wire Solder Wire, typically conforming to AWS A5.18 ER70S-6, offers a balanced chemical composition and excellent mechanical properties.

Typical Chemical Composition (Wt%) - AWS A5.18 ER70S-6

| Element | ER70S-6 (Wt%) Min/Max |

|---|---|

| Carbon (C) | 0.06 - 0.15 |

| Manganese (Mn) | 1.40 - 1.85 |

| Silicon (Si) | 0.80 - 1.15 |

| Phosphorus (P) | 0.025 max |

| Sulfur (S) | 0.035 max |

| Copper (Cu) | 0.50 max |

| Other Elements | 0.50 max |

Typical Mechanical Properties of Weld Metal (Shielding Gas: 100% CO2)

| Property | AWS A5.18 ER70S-6 (Typical) | Unit |

|---|---|---|

| Tensile Strength | 550 - 600 | MPa |

| Yield Strength | 470 - 520 | MPa |

| Elongation | 22 - 28 | % |

| Impact Toughness (CVN) @ -30°C (-22°F) | >47 | Joules |

The high levels of manganese and silicon in ER70S-6 welding solid wire provide excellent deoxidation capabilities, making it suitable for welding over light mill scale or rust. This composition also contributes to the exceptional mechanical properties required for critical structural applications.

Application Scenarios and Target Industries

The versatility and robust performance of Co2 Solid Welding Wire Solder Wire make it an indispensable choice across a broad spectrum of industrial applications. Its ability to produce high-quality welds in various positions and on different material thicknesses positions it as a go-to solution for critical fabrication and repair tasks.

Target Industries:

- Automotive Manufacturing: For chassis, frames, and body components, where strong and consistent welds are critical for safety and structural integrity.

- Construction & Infrastructure: Fabricating structural steel, bridges, pipelines, and heavy machinery, demanding high strength and fatigue resistance.

- Shipbuilding & Marine: Welding hull structures, pressure vessels, and other marine components, requiring excellent mechanical properties and corrosion resistance in harsh environments.

- Energy Sector (Petrochemical, Oil & Gas): Fabrication of pressure vessels, storage tanks, and pipelines that operate under extreme temperatures and pressures, necessitating defect-free welds.

- General Fabrication: Used in countless workshops for general repair, metal furniture, agricultural equipment, and industrial enclosures.

- Water Supply & Drainage: Joining pipes, structural supports, and components for municipal and industrial water systems.

- Metallurgy & Heavy Equipment: Manufacturing of mining equipment, cranes, and other heavy industrial machinery where robust welds are non-negotiable.

Typical Application Scenarios:

- Automated Welding Lines: The consistent feedability and arc stability of our mig solid welding wire make it ideal for robotic and automated welding processes, ensuring high throughput and minimal downtime.

- Multi-Pass Welding: Its excellent slag detachability and minimal inter-pass cleaning requirements contribute to efficiency in multi-pass welding applications on thick sections.

- Fillet and Groove Welds: Capable of producing smooth, well-contoured fillet and groove welds in all positions, reducing grinding and rework.

- Repair and Maintenance: Its robust properties make it suitable for repairing worn or damaged components, extending the service life of industrial assets.

In these scenarios, the wire’s inherent advantages, such as energy-saving due to efficient deposition rates and superior corrosion resistance from its robust metallurgical composition, translate directly into operational cost savings and extended service life for welded components.

Technical Advantages and Performance Metrics

Our Co2 Solid Welding Wire Solder Wire offers a suite of technical advantages that directly translate into improved productivity, reduced costs, and enhanced weld quality for discerning industrial users. These benefits are a direct result of our meticulous manufacturing process and commitment to high standards.

Key Advantages:

- Superior Arc Stability: The consistent chemical composition and copper coating ensure a stable arc, minimizing arc wander and promoting consistent bead formation. This translates to fewer weld defects and reduced rework.

- Low Spatter Levels: Optimized deoxidizers and precise manufacturing result in significantly reduced spatter, leading to less post-weld cleaning, saving labor and consumables. This directly contributes to energy saving by reducing wasted material and energy spent on grinding.

- Excellent Weld Metal Properties: Achieves high tensile strength, yield strength, and impact toughness, ensuring that welded joints can withstand demanding operational stresses and harsh environments, including enhanced corrosion resistance.

- Smooth Wire Feeding: The uniform diameter and precision layer winding, combined with the copper coating, guarantee consistent and trouble-free wire feeding, crucial for automated and high-production welding.

- Versatility in Shielding Gases: While optimized for CO2, this solid mig wire can also perform effectively with Argon-CO2 mixes, offering flexibility in application depending on the desired penetration and bead profile.

- Reduced Hydrogen Content: Minimizes the risk of hydrogen-induced cracking, particularly in welding thicker sections or higher strength steels, ensuring the integrity and longevity of the weld.

These advantages collectively contribute to a lower total cost of ownership for welding operations, enhancing productivity, and ensuring the highest possible quality and reliability of welded components.

Vendor Comparison: Selecting the Right Welding Solid Wire Supplier

Choosing the right supplier for welding solid wire is as critical as selecting the wire itself. A reliable vendor offers consistent product quality, technical support, and competitive pricing. Below is a comparison framework and how our offerings stand out.

Key Comparison Factors:

| Factor | Typical Competitor | Our Co2 Solid Welding Wire Solder Wire |

|---|---|---|

| Quality Certifications | Often only basic ISO 9001 | ISO 9001, AWS A5.18, CE, TUV, Lloyd's Register approval for shipbuilding |

| Wire Consistency | Variable diameter, inconsistent coating, occasional feed issues | Precision drawn, uniform copper coating, excellent feedability |

| Weld Performance | Higher spatter, less stable arc, moderate mechanical properties | Low spatter, highly stable arc, superior mechanical properties (tensile, impact) |

| Technical Support | Limited, basic product data sheets | Dedicated technical engineers, application specialists, comprehensive guides |

| Customization | Rarely offered | Available for specific alloys, diameters, or packaging requirements |

| Lead Time/Fulfillment | Standard 4-6 weeks, less flexible for urgent orders | Standard 2-4 weeks, expedited options available, robust supply chain |

Our commitment to stringent quality control, adherence to global certifications, and proactive customer support distinguishes us in the market. We have been serving the industry for over 15 years, building a reputation for reliability and excellence, a testament to our authoritativeness in the field.

Customized Solutions for Specialized Welding Needs

Recognizing that standard products may not always address every unique industrial challenge, we offer tailored solutions for our solid mig wire products. Our engineering team collaborates closely with clients to develop or modify welding consumables that precisely match their specific application parameters, ensuring optimal performance and cost-efficiency.

Customization Options Include:

- Specialized Chemical Compositions: Adjusting alloy elements to meet specific mechanical property requirements (e.g., higher impact toughness at sub-zero temperatures) or to match challenging base metals.

- Non-Standard Diameters: Producing wire in gauges not typically available off-the-shelf, catering to specialized equipment or precision welding tasks.

- Custom Packaging: Offering alternative spool sizes, bulk drum packaging for robotic applications, or specific winding patterns to enhance feedability in unique setups.

- Surface Treatment Variations: Developing different surface finishes or coating compositions for enhanced corrosion resistance, specific electrical conductivity, or reduced friction in certain feed systems.

Our ability to provide customized mig solid welding wire solutions reflects our deep technical expertise and commitment to partnership. We leverage advanced R&D capabilities and pilot production lines to validate custom specifications before full-scale manufacturing, ensuring that performance metrics are met or exceeded.

Application Case Studies and Customer Feedback

Our welding solid wire has been successfully deployed in numerous demanding projects globally. These case studies highlight the tangible benefits and superior performance delivered to our clients.

Case Study 1: Heavy Equipment Manufacturing

Client: A leading manufacturer of excavators and bulldozers in Asia.

Challenge: High spatter levels and inconsistent weld penetration with their previous mig solid welding wire, leading to increased post-weld cleanup costs and quality rejections on structural components.

Solution: Implementation of our Co2 Solid Welding Wire Solder Wire (AWS ER70S-6, 1.2mm diameter).

Results: Reduced spatter by over 40%, decreasing grinding and cleanup time by 15 hours per week. Achieved full penetration and superior bead aesthetics, leading to a 10% reduction in rework rates and an overall improvement in product quality and fatigue life of welded joints. The client reported significant energy saving due to less re-welding and reduced consumables usage.

Case Study 2: Petrochemical Pipeline Fabrication

Client: A major contractor for oil and gas pipeline infrastructure in the Middle East.

Challenge: Welding API 5L X65 pipeline sections under challenging environmental conditions, requiring high deposition rates while maintaining stringent mechanical properties and resistance to hydrogen-induced cracking.

Solution: Customized batch of our Co2 Solid Welding Wire Solder Wire with enhanced deoxidizer package and carefully controlled hydrogen content.

Results: Successfully passed all radiographic and ultrasonic inspections with zero defects. Deposition rates increased by 8% compared to the previous wire, accelerating project completion. The enhanced corrosion resistance properties of the weld metal ensured long-term integrity of the pipeline, critical for preventing leaks and extending service life in corrosive media.

"Our partnership with [Your Company Name] for solid mig wire has transformed our welding operations. The consistent quality and technical support have significantly boosted our productivity and reduced costs." - Production Manager, Global Automotive Supplier.

Frequently Asked Questions (FAQ)

Q1: What makes your Co2 Solid Welding Wire Solder Wire different from competitors?

A1: Our solid mig wire distinguishes itself through a meticulous manufacturing process, ensuring exceptional consistency in wire diameter, chemical composition, and copper coating. This results in superior arc stability, significantly lower spatter, and excellent feedability, ultimately reducing post-weld cleanup and enhancing overall productivity. We also adhere to stricter quality control standards, holding multiple international certifications beyond basic requirements.

Q2: What are the recommended shielding gases for your welding solid wire?

A2: Our Co2 Solid Welding Wire Solder Wire is primarily optimized for 100% CO2 shielding gas, which provides deep penetration and high deposition rates. It can also be effectively used with Argon-CO2 gas mixtures (e.g., 75% Ar / 25% CO2) for a smoother arc, less spatter, and a broader, flatter bead profile, depending on the specific application requirements.

Q3: How does your wire contribute to energy saving in welding operations?

A3: The superior arc stability and low spatter characteristics of our mig solid welding wire lead to more efficient material deposition, reducing waste and the need for rework. Less post-weld grinding and cleaning directly translate to reduced labor and energy consumption. The consistent feedability minimizes downtime, ensuring continuous operation and optimal energy utilization from your welding equipment.

Q4: What is the typical lead time for large orders?

A4: For standard products, our typical lead time is 2-4 weeks, depending on order size and current production schedule. For customized solutions, lead times will be quoted individually based on the complexity and volume. We maintain robust inventory levels for popular gauges to facilitate faster fulfillment and offer expedited shipping options for urgent requirements.

Trustworthiness: Lead Time, Warranty, and Customer Support

Building lasting relationships with our B2B partners is founded on trust, transparency, and unwavering support. We are committed to providing not only top-tier solid mig wire but also a comprehensive service experience.

Lead Time & Fulfillment:

We understand the critical nature of timely delivery in industrial operations. Our advanced logistics and supply chain management ensure efficient processing of orders. Standard lead times for our Co2 Solid Welding Wire Solder Wire are typically 2-4 weeks, depending on quantity and specific requirements. For urgent demands, we offer expedited production and shipping options. Our robust inventory management system minimizes delays, ensuring your projects stay on schedule.

Warranty Commitments:

All our welding solid wire products are backed by a comprehensive warranty against manufacturing defects and non-conformance to stated specifications. This warranty covers material quality, dimensional accuracy, and performance characteristics as per AWS, ISO, and other relevant industry standards. Full warranty terms and conditions are available upon request, providing you with complete peace of mind.

Dedicated Customer Support:

Our commitment extends beyond product delivery. We provide dedicated customer support through a team of experienced technical engineers and sales professionals. This includes:

- Pre-Sales Consultation: Expert advice on selecting the optimal mig solid welding wire for your specific application.

- Technical Assistance: On-site or remote support for troubleshooting, process optimization, and performance analysis.

- After-Sales Service: Prompt response to any queries or concerns regarding product performance or quality.

- Training: Customized training programs for your welding technicians to maximize the benefits of our consumables.

We believe in building long-term partnerships, and our comprehensive support system is designed to ensure your continuous success with our products.

Conclusion

The selection of high-quality solid mig wire is a critical decision that impacts weld integrity, operational efficiency, and overall project profitability. Our Co2 Solid Welding Wire Solder Wire exemplifies excellence in welding consumables, offering a meticulously engineered product backed by stringent quality control and comprehensive technical support. By understanding its advanced manufacturing, precise technical specifications, and broad application potential across key industries, businesses can leverage this superior welding solid wire to achieve stronger, more reliable, and cost-effective welds, contributing to significant energy saving and enhanced service life of fabricated components.

As industrial demands continue to evolve, our commitment remains unwavering: to provide innovative, high-performance mig solid welding wire solutions that empower our partners to excel in their most challenging projects.

References:

- American Welding Society. (2019). AWS A5.18/A5.18M: Specification for Carbon Steel Electrodes and Rods for Gas Shielded Arc Welding.

- International Organization for Standardization. (2015). ISO 9001: Quality management systems – Requirements.

- The Welding Institute (TWI). (2022). "Advances in MIG/MAG Welding Technology". TWI Industry Reports.

- Mordor Intelligence. (2023). "Welding Consumables Market - Growth, Trends, COVID-19 Impact, and Forecasts (2023 - 2028)".

-

High-Quality Welding Electrodes 4.0mm*400mm for Industrial Use | Steel Tools ChinaNewsNov.24,2025

-

Explore the Benefits and Uses of 2.6mm Welding Electrode 6013 | Global GuideNewsNov.23,2025

-

Understanding CO2 Welding Wire Price: Global Impact, Trends, and TipsNewsNov.22,2025

-

Top Guide to Welding Wires CO2 – Specifications, Benefits & Industry UsesNewsNov.22,2025

-

Comprehensive Guide to Welding Electrode 6011 – Global Applications & BenefitsNewsNov.21,2025

-

AWS E6013 Welding Rod-HEBEI YUJINHONG TECHNOLOGY CO.,LTD.|All-Position Carbon Steel ElectrodeNewsNov.21,2025