Production Description

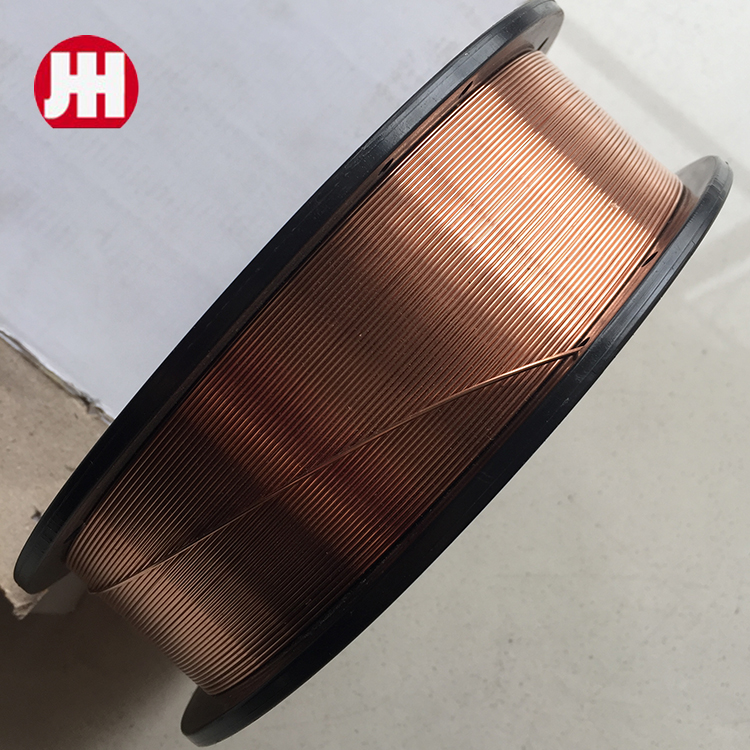

Alambre wire

The Welding Wire ER70S-6 is 500MPa level carbon steel wire. It take CO2 or 80%Ar + 20%CO2 gas shielded arc welding. The welding

spatter is small, and it has beautiful appearance, high cladding efficiency and small weld metal porosity sensibility. The welding

technology of all positions is good.

Welding Positions:

PA、PB、PC、PD、PE、PF

Gas shielded welding is divided into inert gas shielded welding (TIG welding and MIG welding), active gas shielded welding (MAG welding) and self shielded welding. Pure Ar is used for TIG welding, and Ar + 2% O2 or Ar + 5% CO2 is generally used for MIG welding. MAG welding mainly uses CO2 gas. In order to improve the process performance of CO2 welding, CO2+Ar or CO2+Ar+O2 mixed gas or flux cored wire can also be used.

- TIG welding wire

TIG welding sometimes does not add filler wire, which is directly connected after being heated and melted by the base metal to be welded, and sometimes adds filler wire, because the shielding gas is pure Ar, non-oxidizing, and the composition of the wire does not change basically after melting, so the composition of the wire is the welding wire seam components. Some also use the base metal composition as the welding wire composition to make the weld composition consistent with the base metal. During TIG welding, the welding energy is small, the weld strength, plasticity and toughness are good, and it is easy to meet the performance requirements.

- MIG and MAG welding wire

The MIG method is mainly used for welding high-alloy steels such as stainless steel. In order to improve the arc characteristics, add an appropriate amount of 02 or CO2 gas to the Ar gas, which becomes the MAG method. When welding alloy steel, the use of Ar + 5% CO2 can improve the anti-porosity ability of the weld. However, when welding ultra-low carbon stainless steel, Ar + 5% CO2 mixed gas cannot be used, and only Ar + 2% O2 mixed gas can be used to prevent weld carburization. At present, MIG welding of low alloy steel is gradually being replaced by MAG welding of Ar + 20% CO2. During MAG welding, due to the oxidizing properties of the shielding gas, the content of deoxidizing elements such as Si and Mn in the welding wire should be appropriately increased. Other components can be the same as the base metal, or they can be different. When welding high-strength steel, the content of C in the weld is usually lower than that of the base metal, and the content of Mn should be higher than that of the base metal. This is not only for deoxidation, but also a requirement for the alloy composition of the weld. In order to improve the low temperature toughness, the content of Si in the weld should not be too high.

|

C |

Mn |

Si |

S |

P |

Ni |

Cr |

Mo |

V |

Cu |

|

0.06-0.15 |

1.4-1.85 |

0.8-1.15 |

≤0.025 |

≤0.025 |

≤0.15 |

≤0.15 |

≤0.15 |

≤0.03 |

≤0.5 |

Mechanical Property:

|

AWS |

Tensile Strength Rm |

Yield Strength Rel/Rp0.2 |

A |

KV2 (-30C)/J |

|

MPa |

MPa |

% |

0 degree/J |

|

|

ER70S-6 |

≥500 |

≥420 |

≥22 |

≥27 |

Specification & Package

0.8mm, 5kgs/box, 15kg per box. 20kg/box

0.9mm, 5kgs/box, 15kg per box. 20kg/box

1.0mm, 5kgs/box, 15kg per box. 20kg/box

1.2mm, 5kgs/box, 15kg per box. 20kg/box

1.6mm, 5kgs/box, 15kg per box. 20kg/box

Color print box is available.

OEM/ODM Package Available:

we also can do different kgs package, different brand print.

we can print the package as your requests, we have professional designer to make the package design with your brand & LOGO.

Product Video

Visit & Exhibition

Welcome to visit us for a friendly and long term cooperation, please tell us your time schedule, we will arrange for you. we will also join the relate exhibitions, we can meet each other on the exhibition. Friendship first, and business is professional, you can trust us forever.

Do you have the following trouble when order the products?

1.Is the Supplier Reliable?

We produce this products more than 30 years, we have advertise on Alibaba, Made-in-China, after you place the order, whenever you want to see the production, we can send you video or picture to check. Our export team also have more than 15 years experience, we can solve all the problem you may meet in business. Welcome to visit us.

2.Is the Quality Stable?

We do test randomly in production, and test shipment before ex works. We have professional QC workers and high level test equipment, to assure each shipment in good quality.

3.Is the Payment Safe?

We choose one of the largest bank in China, to assure your payment will arrive in safe condition, and all of the benefit company must send them the shipping document copy to bank for record.

4.Shipment Delivery?

Normally we can arrange shipment in 15 days, if customize the package, shipment can be arranged in one month, please negotiate with our customer service, we will tell you a firm date after check our production and your order quantity.

Please don't hesitate to contact us

Sales Manager: Cherry Zhang

Tel: 0086-311-68035766

Fax: 0086-311-68035566

Mobile: 008613739727566

WhatsApp / Wechat: 008613739727566

Email: info@steeltoolschina.com

Send inquiry