Jun . 24, 2024 02:40

Back to list

Stick Welding Rods Manufacturing Plants

The Evolution of Stick Welding Rods Factories

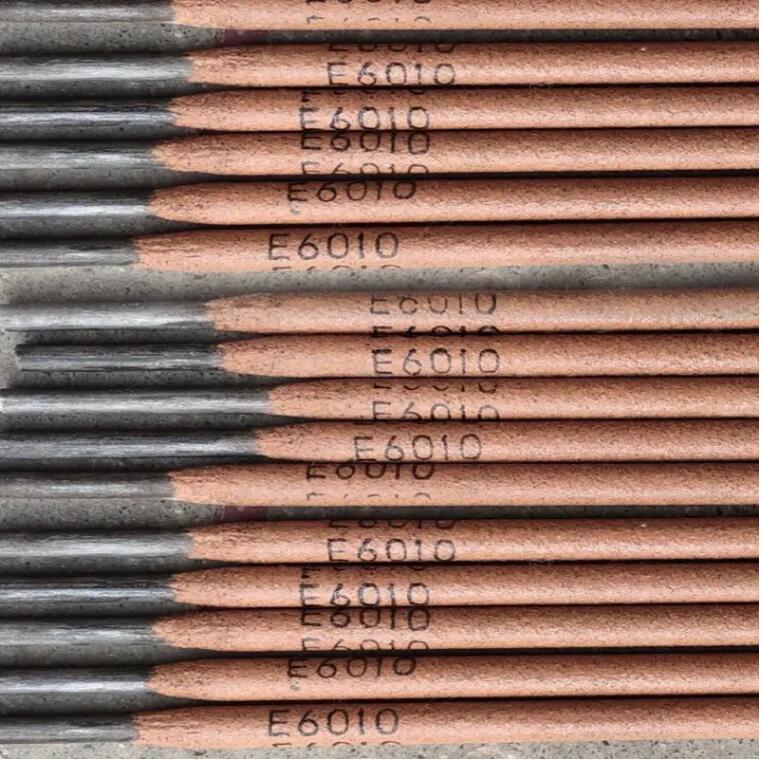

Stick welding, also known as manual metal arc welding, is a widely used process across various industries. At the heart of this process are stick welding rods, which serve as both electrode and filler material. Over the years, stick welding rods factories have played a crucial role in shaping the manufacturing landscape, adapting to technological advancements and market demands.

The origins of stick welding rods factories can be traced back to the early 20th century when the need for efficient and reliable welding methods became paramount. These factories were initially small-scale operations, focusing on producing quality rods for local consumption. However, with the advent of industrialization, they quickly expanded their production capacities to meet the growing demand from sectors such as construction, automotive, and shipbuilding.

One significant development in the evolution of stick welding rods factories was the introduction of automation. This shift allowed for increased productivity and consistency in the manufacturing process. Highly specialized machines replaced manual labor in tasks such as rod preparation, coating application, and packaging. As a result, factories could produce a wider range of rods tailored to specific applications, including those designed for high-temperature or corrosive environments.

In parallel with these technological advancements, stick welding rods factories also faced challenges related to environmental regulations and sustainability practices

In parallel with these technological advancements, stick welding rods factories also faced challenges related to environmental regulations and sustainability practices In parallel with these technological advancements, stick welding rods factories also faced challenges related to environmental regulations and sustainability practices

In parallel with these technological advancements, stick welding rods factories also faced challenges related to environmental regulations and sustainability practices

In parallel with these technological advancements, stick welding rods factories also faced challenges related to environmental regulations and sustainability practices

In parallel with these technological advancements, stick welding rods factories also faced challenges related to environmental regulations and sustainability practices stick welding rods factories. The industry responded by implementing eco-friendly measures such as reducing energy consumption during production, utilizing recycled materials, and minimizing waste output. Some factories even began exploring the use of alternative materials that could potentially reduce the environmental impact associated with welding.

Today's stick welding rods factories are complex entities that not only focus on producing high-quality products but also on innovation and sustainability. They stand at the intersection of tradition and modernity, balancing time-honored techniques with cutting-edge technology. As we look towards the future, it is evident that these factories will continue to evolve, driven by an unwavering commitment to excellence and an ever-present eye on environmental stewardship.

In conclusion, stick welding rods factories have undergone remarkable transformations since their inception. From humble beginnings to embracing automation and sustainability, these facilities showcase the dynamic nature of manufacturing. They remain integral to global industries, ensuring that the welds binding critical infrastructure are strong and enduring—a testament to their resilience and adaptability over time.

stick welding rods factories. The industry responded by implementing eco-friendly measures such as reducing energy consumption during production, utilizing recycled materials, and minimizing waste output. Some factories even began exploring the use of alternative materials that could potentially reduce the environmental impact associated with welding.

Today's stick welding rods factories are complex entities that not only focus on producing high-quality products but also on innovation and sustainability. They stand at the intersection of tradition and modernity, balancing time-honored techniques with cutting-edge technology. As we look towards the future, it is evident that these factories will continue to evolve, driven by an unwavering commitment to excellence and an ever-present eye on environmental stewardship.

In conclusion, stick welding rods factories have undergone remarkable transformations since their inception. From humble beginnings to embracing automation and sustainability, these facilities showcase the dynamic nature of manufacturing. They remain integral to global industries, ensuring that the welds binding critical infrastructure are strong and enduring—a testament to their resilience and adaptability over time.

In parallel with these technological advancements, stick welding rods factories also faced challenges related to environmental regulations and sustainability practices

In parallel with these technological advancements, stick welding rods factories also faced challenges related to environmental regulations and sustainability practices

In parallel with these technological advancements, stick welding rods factories also faced challenges related to environmental regulations and sustainability practices

In parallel with these technological advancements, stick welding rods factories also faced challenges related to environmental regulations and sustainability practices stick welding rods factories. The industry responded by implementing eco-friendly measures such as reducing energy consumption during production, utilizing recycled materials, and minimizing waste output. Some factories even began exploring the use of alternative materials that could potentially reduce the environmental impact associated with welding.

Today's stick welding rods factories are complex entities that not only focus on producing high-quality products but also on innovation and sustainability. They stand at the intersection of tradition and modernity, balancing time-honored techniques with cutting-edge technology. As we look towards the future, it is evident that these factories will continue to evolve, driven by an unwavering commitment to excellence and an ever-present eye on environmental stewardship.

In conclusion, stick welding rods factories have undergone remarkable transformations since their inception. From humble beginnings to embracing automation and sustainability, these facilities showcase the dynamic nature of manufacturing. They remain integral to global industries, ensuring that the welds binding critical infrastructure are strong and enduring—a testament to their resilience and adaptability over time.

stick welding rods factories. The industry responded by implementing eco-friendly measures such as reducing energy consumption during production, utilizing recycled materials, and minimizing waste output. Some factories even began exploring the use of alternative materials that could potentially reduce the environmental impact associated with welding.

Today's stick welding rods factories are complex entities that not only focus on producing high-quality products but also on innovation and sustainability. They stand at the intersection of tradition and modernity, balancing time-honored techniques with cutting-edge technology. As we look towards the future, it is evident that these factories will continue to evolve, driven by an unwavering commitment to excellence and an ever-present eye on environmental stewardship.

In conclusion, stick welding rods factories have undergone remarkable transformations since their inception. From humble beginnings to embracing automation and sustainability, these facilities showcase the dynamic nature of manufacturing. They remain integral to global industries, ensuring that the welds binding critical infrastructure are strong and enduring—a testament to their resilience and adaptability over time. Latest news

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025