Piezoelectricity is the electric charge that accumulates in certain solid materials in response to applied mechanical stress. Materials exhibiting the piezoelectric effect also exhibit the reverse – the internal generation of a mechanical strain resulting from an applied electrical field. Andy Pye reviews the developments in this area, with special emphasis on polymer formulations.

electrodes-Piezoelectric Materials

Piezoelectric Materials

Before World War II, researchers discovered that certain ceramic materials could be made piezoelectric when subjected to a high polarising voltage, a process analogous to magnetising a ferrous material. One of the first practical applications of the technology was made in the 1920’s by another Frenchman, Langevin, who developed a quartz transmitter and receiver for underwater sound – the first sonar.

Piezoelectricity is exploited in applications such as the production and detection of sound, generation of high voltages, electronic frequency generation, microbalances, to drive an ultrasonic nozzle, and ultrafine focusing of optical assemblies. It is the basis of a number of scientific instrumental techniques with atomic resolution, the scanning probe microscopies such as STM, AFM, MTA and SNOM, as well as everyday uses, such as acting as the ignition source for cigarette lighters, push-start propane barbecues, and quartz watches.

A piezoelectric sensor is a device that uses the piezoelectric effect, to measure changes in pressure, acceleration, temperature, strain, or force by converting them to an electrical charge. Although originally discovered in 1880 by French physicists Jacques and Pierre Curie, it was only in the 1950s that manufacturers begin to use the piezoelectric effect in industrial sensing applications. Since then, this measuring principle has been increasingly used, and has become a mature technology with excellent inherent reliability. It has been successfully used in medical, aerospace, nuclear instrumentation, as a tilt sensor in consumer electronics or a pressure sensor in the touch pads of mobile phones.

In the automotive industry, piezoelectric elements are used to monitor combustion when developing internal combustion engines. The sensors are either directly mounted into additional holes into the cylinder head or the spark/glow plug is equipped with a built-in miniature piezoelectric sensor.

Sensing materials

There are three basic classes of piezoelectric materials used in microfabrication:

- natural piezoelectric substrates, such as quartz single crystals

- piezoelectric ceramics, such as lithium niobate, gallium arsenide, zinc oxide, aluminium nitride and lead zirconate-titanate (PZT)

- polymer-film piezoelectrics, such aspolyvinylidene fluoride (PVDF).

The ceramic materials, such as PZT, have a piezoelectric constant/sensitivity that is roughly two orders of magnitude higher than those of the natural single crystal materials and can be produced by inexpensive sintering processes. The piezoeffect in piezoceramics is “trained”, so their high sensitivity degrades over time. This degradation is highly correlated with increased temperature.

PZT Ceramics

The most commonly used type of piezoceramics, Lead Zirconate Titanates (PZTs), are solid solutions of lead zirconate and lead titanate, often doped with other elements to obtain specific properties. These ceramics are manufactured by mixing together proportional amounts of lead, zirconium and titanium oxide powders and heating the mixture to around 800 to 1000C. They then react to form perovskite PZT powder. This powder is mixed with a binder and sintered into the desired shape. During the cooling process, the material undergoes a phase transition from paraelectric to ferroelectric and the cubic unit cell becomes tetragonal. As a result, the unit cell becomes elongated in one direction and has a permanent dipole moment oriented along its long axis (c-axis). The unpoled ceramic consists of many randomly oriented domains and thus has no net polarization.

Application of a high electric field has the effect of aligning most of the unit cells as closely parallel to the applied field as possible. This process is called poling and it imparts a permanent net polarisation to the ceramic. The material in this state exhibits both direct and converse piezoelectric effects.

PZT sensors exhibit most of the characteristics of ceramics, namely a high elastic modulus, brittleness and low tensile strength. The material itself is mechanically isotropic, and by virtue of the poling process, is assumed transversely isotropic in the plane normal to the poling direction as far as piezoelectric properties are concerned.

Galliumarsenide-based amplifiers and filters are already available on the market and this new discovery opens up new ways of integrating antennas on a chip along with other components. Working with the National Physical Laboratory and Cambridge-based dielectric antenna company Antenova, a team of Cambridge University researchers has found that, at a certain frequency, thin films of piezoelectric materials not only become efficient resonators, but efficient radiators as well, meaning that they can be used as aerials.

The less-sensitive, natural, single-crystal materials (gallium phosphate, quartz, tourmaline) have a higher – when carefully handled, almost unlimited – long term stability. There are also new single-crystal materials commercially available such as Lead Magnesium Niobate-Lead Titanate (PMN-PT). These materials offer improved sensitivity over PZT but have a lower maximum operating temperature and are currently more expensive to manufacture.

PVDF polymer films

In 1969, very high piezo-activity was observed in the polarisedfluoropolymer,polyvinylidene fluoride (PVDF). While other materials, likenylonand PVC exhibit the effect, none conduct piezoelectricity as well as PVDF and its copolymers.

PVDF is one of a select group families of formulations that have exceptional electric and electronic versatility – these most versatile compounds widely used in the new electronics and electrical industries turn out to be based on one of six anions and three polymer families. Developers see PVDF formulations as a gymnast of materials offering:

- Piezoelectricfor sensors and energy harvesting

- Semiconductorfor transistors,diodes,photovoltaicswhen filled with conductive fillers carbon black,nickel, zinc, ortungsten

- Ferroelectric for printable memory, particularly with chlorine side chains

- Insulator for many electric and electronic devices

- Dielectricfor many electric and electronic devices such as newcapacitorsor transistor gates

- Electret inmicrophonesetc.

- Separator/porous membrane inProton Exchange MembranePEM fuel cells and the new lithium metal rechargeable batteries

- Active electrode binder inlithium-ion batteries

Piezoelectricity conducting PVDF film is a flexible, lightweight, tough engineering plastic available in a wide variety of thicknesses and large areas. Its properties as a transducer include:

- Wide frequency range: 0.001 to 109Hz.

- Vast dynamic range (10-8 to 106psi or µ torr to Mbar).

- Low acoustic impedance—close match to water, human tissue and adhesive systems.

- High elastic compliance

- High voltage output—10 times higher than piezo ceramics for the same force input.

- High dielectric strength—withstanding strong fields (75V/µm) where most piezo ceramics depolarise.

- High mechanical strength and impact resistance (109 to 1010 Pascal modulus).

- High stability: resistant moisture (<0.02% moisture absorption), most chemicals, oxidants, and intense ultraviolet and nuclear radiation.

- Can be fabricated into unusual designs.

- Can be glued with commercial adhesives.

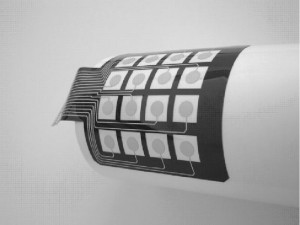

Piezo film has low density and excellent sensitivity, and is mechanically tough. The compliance of piezo film is 10 times greater than the compliance of ceramics. When extruded into thin film, polymers that conduct piezoelectricity can be directly attached to a structure without disturbing its mechanical motion. Piezo film is well suited to strain sensing applications requiring very wide bandwidth and high sensitivity. As an actuator, the polymer’s low acoustic impedance permits the efficient transfer of a broadband of energy into air and other gases.

In spite of their lower coefficients of piezoelectricity, these characteristics make PVDF films more attractive than PZT ceramics for sensor applications. Piezoelectric polymer film sensors are among the fastest growing of the technologies within the $18 billion worldwide sensor market. Like any new technology, there have been an extraordinary number of applications considered for the sensor.

The Young’s modulus of PZT is comparable to that of aluminium, whereas that of PVDF is approximately 1/12th that of aluminium. It is therefore much more suited to sensing applications since it is less likely to influence the dynamics of the host structure as a result of its own stiffness. It is also very easy to shape PVDF film for any desired application.

Push buttons for keyboards, keypads, and control panels with small areas have been made with cellular piezoelectric polymer films. Keypads are commercially produced by the Screentec company in Finland, and are used for example, in interfaces for information systems in public transportation or as access readers for different applications. The high sensitivity allows the implementation of the sensors behind protective layers of different materials (with a thickness up to 5mm) to achieve vandal-proof control panels usable for cash dispensers and ticket machines or other systems in public transportation.

A major advantage of piezo film over piezo ceramic is its low acoustic impedance, which is closer to that of water, human tissue and other organic materials. A close impedance match permits more efficient transduction of acoustic signals in water and tissue. For example, the acoustic impedance of piezo film is only 2.6 times that of water, whereas piezo ceramics are typically 11 times greater.

Piezo film does have some limitations for certain applications. Compared to ceramics, it makes a relatively weak electromechanical transmitter, particularly at resonance and in low frequency applications. Also, if the electrodes on the film are exposed, the sensor can be sensitive to electromagnetic radiation, though good shielding techniques are available for high EMI/RFI environments.

PVDF consists of long chains of the repeating monomer (—CH2—CF2—). The hydrogen atoms are positively charged and the fluorine atoms are negatively charged with respect to the carbon atoms and this leaves each monomer unit with an inherent dipole moment. PVDF film is manufactured by solidification of the film from a molten phase, which is then stretched in a particular direction and finally poled. In the liquid phase, the individual polymer chains are free to take up any orientation and so a given volume of liquid has no net dipole moment.

After solidification, and stretching the film in one direction, the polymer chains are mostly aligned along the direction of stretching. This, combined with the poling, imparts a permanent dipole moment to the film, which then behaves like a piezoelectric material.

The process of stretching the film, which orients the polymer chains in a specific direction, renders the material piezoelectrically orthotropic. For small strains, however, the material is considered mechanically isotropic.

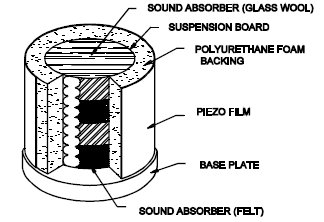

New copolymers of PVDF, developed over the last few years, have expanded the applications of piezoelectric polymer sensors. These copolymers permit use at higher temperatures (135C) and offer desirable new sensor shapes, like cylinders and hemispheres. Thickness extremes are possible with copolymer that cannot be readily attained with PVDF. These include ultra-thin (200Å) spin-cast coatings that enable new sensor-on-silicon applications, and cylinders with wall thicknesses in excess of 1200 microns for sonar. The copolymer film has a maximum operating/storage temperature of 135C, and PVDF is not recommended for use or storage above 100C.

PVDF is also pyroelectric, producing electrical charge in response to a change in temperature. It strongly absorbs infrared energy in the 7-20µm wavelengths, covering the same wavelength spectrum as heat from the human body. Accordingly, PVDF makes a useful human motion sensor as well as a pyroelectric sensor for more sophisticated applications like cameras for night vision and laser beam profiling sensors. A dense infrared array has been recently introduced that identifies one’s fingerprint pattern using the pyro effect of piezo polymer.

ElectroMechanical Film (EMFi)

EMFi is a thin polypropylene (PP) material having a special cellular structure. The internal structure of EMFi is made be stretching the PP preform during the manufacturing process in longitudinal and transversal directions. The film is charged with a corona discharge method using electric field strength locally exceeding the film dielectric strength. Finally, the film is coated with electrically conductive electrode layers.

The EMFi material consists of three layers: smooth and homogenous surface layers and a dominant, thicker mid-section. The mid-section is full of flat gas voids separated by leaf-like PP-layers. The voids can be compared to large electrical dipoles that are easily compressed in thickness direction by externally applied pressure.

In tests, the sensitivity of the EMFi sensor in the normal force direction has been found to be approximately five-fold when compared to the corresponding value of the PVDF sensor. The higher sensitivity of the EMFi material is mainly due to the internal voided structure. However, due to the relatively large gas voids and local corona breakdowns, sensitivity varies in different parts of the film.

Because the base material of EMFi is inexpensive PP, it is applicable also for large area sensors, like floor monitoring systems. Compared to the EMFi material, piezoelectric polymers usually contain fluoride, which is a potentially toxic substance. The main advantage of PVDF, however, is its sensitivity to forces related to its length and width. This property creates many versatile applications for the material: for example, it can be utilised also as a shear stress sensor.

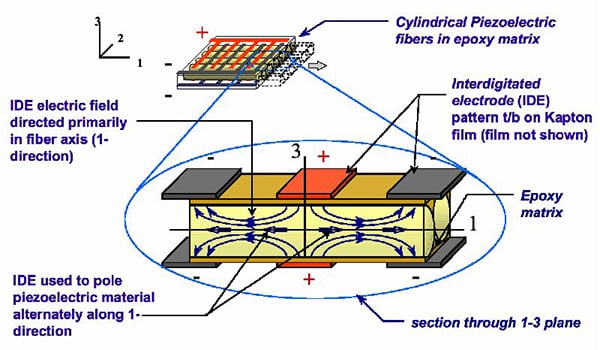

PZT Fibres

The nature of the ceramic monolithic piezoelectric material makes them brittle and vulnerable to accidental breakage during handling and bonding procedures as well as in the service intended. In addition, they have poor ability to conform to curved surfaces and are very dense and stiff causing mass loading and localized stiffness. These limitations have encouraged researchers to develop alternative methods of manufacturing the piezoelectric ceramics in order to make them more suitable for the next generation of piezoelectric applications.

In order to resolve the inadequacy of the monolithic piezoelectric ceramic material for many applications, the idea of using a composite material consisting of an active piezoelectric ceramic fibrous phase embedded in a polymeric matrix phase has been investigated by a number of researchers. Piezo ceramic fibres have been produced through a patented injection moulding process. In addition to this added strength of the base material, the flexibility of the polymer matrix allows the piezoelectric ceramic fibres to have greater conformability to curved surfaces and provides a protective shell around the piezoelectric material. This polymer shell allows the piezoelectric-fibre to withstand impacts and harsh environments far better than monolithic piezoelectric materials. The result of configuring the piezoelectric fibre inside a polymer matrix is an actuator that can be incorporated into or bonded to more realistic structures.

This soft moulding process holds many advantages over the previously useddie-and-fill,injection mouldingor dicing techniques, due to the moulds being reusable, allowing thousands of identical actuators to be made. In addition, the fabrication is relatively easy and cost effective because of the simplicity of the mould construction when compared to the other options for fibre construction. Once the brittle fibres are formed a polymer matrix is added to the remaining spaces to protect the fibres from breakage. Subsequent to this process is the addition of metal electrodes for poling of the device, later to be used as a means of applying an electric field or measuring the current produced during sensing.

The procedure combines PZT powder with a wax-based binder, and then the material is granulated as feedstock for the injection moulding process. Once this is completed the feedstock is heated to the specified viscosity and rapidly injected at high pressure into a cooled mould. Due to the incompressible nature of the material, when injected into the mould the fibres obtain a constant density throughout and remove of voids and internal defects that occur during dry pressing or low pressure forming methods. The homogeneous density of the material produces uniform microstructures, dimensions and electromechanical properties after firing.

-

Main components required for stick weldingNewsApr.03,2025

-

Welding fire accidentsNewsApr.02,2025

-

Composition of electrode welding equipmentNewsApr.01,2025

-

What are the advantages of submerged arc welding?NewsMar.31,2025

-

Welder weldingNewsMar.27,2025

-

Insulation measures must be taken when welding in a humid environmentNewsMar.25,2025