Jan . 15, 2025 05:27

Back to list

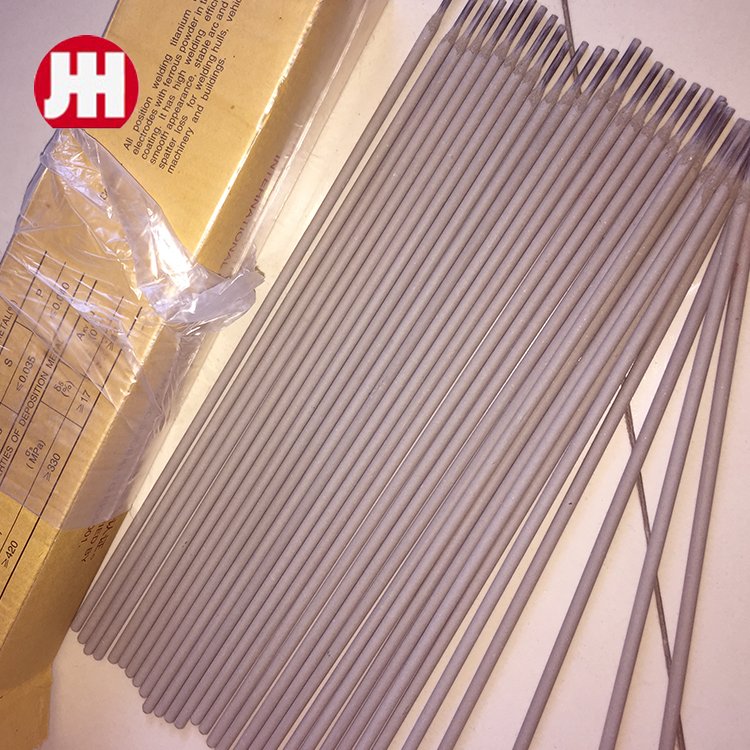

3.2mm 4mm 7018 welding rods electrodes

Finding the right welding wire can be a game-changer for professionals requiring precision and efficiency in their welding efforts. Whether you're engaged in heavy industrial work, construction, or intricate automotive repairs, selecting the appropriate welding wire size and type becomes crucial. Let's delve into the world of the 1.2mm welding wire, exploring its unique characteristics and how it can be applied for optimized performance.

When it comes to expertise and specialization, the use of the 1.2mm welding wire is not limited to plain carbon steel alone. It extends its capabilities to stainless steel and aluminum, making it a quintessential choice for projects that demand high corrosion resistance and superior finish quality. The adaptability to different metals underscores its vital role in both construction and manufacturing industries, where diverse material needs are a constant. Trustworthiness in welding involves using components that adhere to industry standards, and the 1.2mm welding wire does not disappoint. Many manufacturers comply with international regulations to ensure their wires meet the desired mechanical properties and performance levels. Quality assurance is a non-negotiable component, ensuring each spool of wire is engineered with precision, offering welders the peace of mind they require as they undertake critical projects. In terms of authoritativeness, feedback from industry veterans highlights the effectiveness of 1.2mm wires in improving workflow efficiencies. Experts often recommend these wires for projects requiring precision such as building frameworks, automotive chassis, and even delicate components in aerospace engineering. Welding instructors and seasoned professionals often emphasize the cost-effectiveness and reliability of the 1.2mm wire, especially when fused with advanced welding technologies like MIG (Metal Inert Gas) and TIG (Tungsten Inert Gas) methods. Ultimately, the right welding wire can significantly impact both the quality of the work and the efficiency of the process. For many professionals in welding, the 1.2mm wire represents a perfect blend of size, performance, and reliability. Its multifaceted applications and recognition from industry experts render it an indispensable component in the welders' arsenal. With optimal usage, not only do welders execute with precision, but they also ensure their projects endure the test of time, thus earning the trust of peers and clients alike.

When it comes to expertise and specialization, the use of the 1.2mm welding wire is not limited to plain carbon steel alone. It extends its capabilities to stainless steel and aluminum, making it a quintessential choice for projects that demand high corrosion resistance and superior finish quality. The adaptability to different metals underscores its vital role in both construction and manufacturing industries, where diverse material needs are a constant. Trustworthiness in welding involves using components that adhere to industry standards, and the 1.2mm welding wire does not disappoint. Many manufacturers comply with international regulations to ensure their wires meet the desired mechanical properties and performance levels. Quality assurance is a non-negotiable component, ensuring each spool of wire is engineered with precision, offering welders the peace of mind they require as they undertake critical projects. In terms of authoritativeness, feedback from industry veterans highlights the effectiveness of 1.2mm wires in improving workflow efficiencies. Experts often recommend these wires for projects requiring precision such as building frameworks, automotive chassis, and even delicate components in aerospace engineering. Welding instructors and seasoned professionals often emphasize the cost-effectiveness and reliability of the 1.2mm wire, especially when fused with advanced welding technologies like MIG (Metal Inert Gas) and TIG (Tungsten Inert Gas) methods. Ultimately, the right welding wire can significantly impact both the quality of the work and the efficiency of the process. For many professionals in welding, the 1.2mm wire represents a perfect blend of size, performance, and reliability. Its multifaceted applications and recognition from industry experts render it an indispensable component in the welders' arsenal. With optimal usage, not only do welders execute with precision, but they also ensure their projects endure the test of time, thus earning the trust of peers and clients alike.

Latest news

-

High-Quality Welding Electrodes 4.0mm*400mm for Industrial Use | Steel Tools ChinaNewsNov.24,2025

-

Explore the Benefits and Uses of 2.6mm Welding Electrode 6013 | Global GuideNewsNov.23,2025

-

Understanding CO2 Welding Wire Price: Global Impact, Trends, and TipsNewsNov.22,2025

-

Top Guide to Welding Wires CO2 – Specifications, Benefits & Industry UsesNewsNov.22,2025

-

Comprehensive Guide to Welding Electrode 6011 – Global Applications & BenefitsNewsNov.21,2025

-

AWS E6013 Welding Rod-HEBEI YUJINHONG TECHNOLOGY CO.,LTD.|All-Position Carbon Steel ElectrodeNewsNov.21,2025