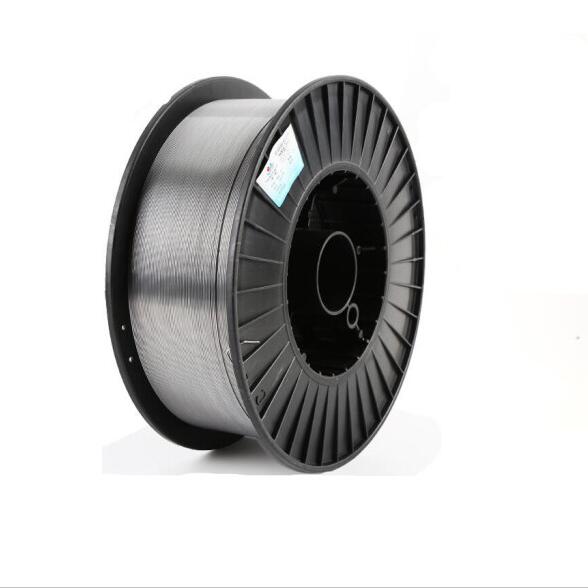

wholesale best arc welding rod manufacturers

The Rise of Wholesale Arc Welding Rod Manufacturers

In today's industrial landscape, arc welding remains a cornerstone of manufacturing and construction, providing robust solutions for joining metals. The efficiency and effectiveness of arc welding largely depend on the quality of the welding rods used. As the demand for high-quality welding rods rises, wholesale arc welding rod manufacturers are playing an increasingly crucial role in the industry.

Arc welding rods, also known as welding electrodes, are essential for creating strong welds in various applications, ranging from automotive to heavy machinery. The global construction boom and the ongoing infrastructure projects have significantly boosted the need for durable and reliable welding materials. This surge in demand has led to a proliferation of wholesale manufacturers, eager to cater to both small and large-scale businesses.

One of the main advantages of selecting wholesale suppliers is the cost-effectiveness they offer. By purchasing in bulk, companies can benefit from lower prices per unit, which can significantly reduce overall project costs. Moreover, wholesale manufacturers often provide a wider range of products, allowing businesses to find the specific type of welding rod that suits their unique needs, whether it's for mild steel, stainless steel, or aluminum applications.

wholesale best arc welding rod manufacturers

Quality assurance is another critical factor that wholesale arc welding rod manufacturers focus on. To stand out in a competitive market, many manufacturers adhere to international standards and certifications, ensuring that their products meet or exceed industry expectations. This commitment to quality fosters trust among clients, making them more likely to return for future orders.

Furthermore, advancements in technology have also influenced the manufacturing processes of welding rods. Modern wholesale manufacturers leverage state-of-the-art techniques and machinery to produce welding rods that not only meet high performance standards but also improve safety during the welding process. Innovations such as improved coating materials and enhanced rod composition contribute to more effective arc stability and less spatter, thereby increasing overall efficiency.

Another vital aspect to consider is the environmental impact of welding practices. Many contemporary manufacturers are now focusing on producing eco-friendly welding rods. This shift is essential in today's economy, where sustainability is a pivotal concern. Manufacturers are developing rods that emit fewer fumes and are made from recycled materials, aligning their production processes with global efforts towards environmental conservation.

In conclusion, wholesale arc welding rod manufacturers are integral to supporting the growing demands of modern industries. By providing cost-effective, high-quality products with a commitment to innovation and sustainability, they play a vital role in the success of various sectors. As businesses continue to seek reliable partners in their manufacturing endeavors, the significance of these manufacturers will only continue to rise.

-

Premium Submerged Arc Welding Wire | Efficient Quality SolutionNewsJul.21,2025

-

Premium Solid MIG Welding Wire - Strong, Low-Spatter WeldsNewsJul.21,2025

-

E71T-GS Self-Shielding Welding Wire | Gasless Outdoor UseNewsJul.20,2025

-

E312 Welding Electrode - High Corrosion Resistance & All-Purpose UseNewsJul.20,2025

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025