Premium Solid MIG Welding Wire - Strong, Low-Spatter Welds

HEBEI YUJINHONG TECHNOLOGY CO.,LTD.

- Website: www.steeltoolschina.com

- Phone: 0086-137 3972 7566

- Email: info@steeltoolschina.com

- Mobile: 0086-311-68035766

- Address: NO.368 YOUYI NORTH STREET, XINHUA DISTRICT, SHIJIAZHUANG CITY, CHINA

Introduction to Solid MIG Welding Wire

Solid MIG wire has become an indispensable component in modern fabrication industries, revolutionizing how professionals approach metal joining. This comprehensive guide examines the latest trends, technical parameters, and applications of MIG solid welding wire, with a particular focus on premium-grade materials manufactured by industry leaders.

The welding industry has witnessed significant transformation over the past decade, with the welding solid wire segment experiencing a 12.7% compound annual growth rate according to recent market analysis. This growth is driven by increased infrastructure development globally and technological advancements that have improved both performance characteristics and operational efficiencies.

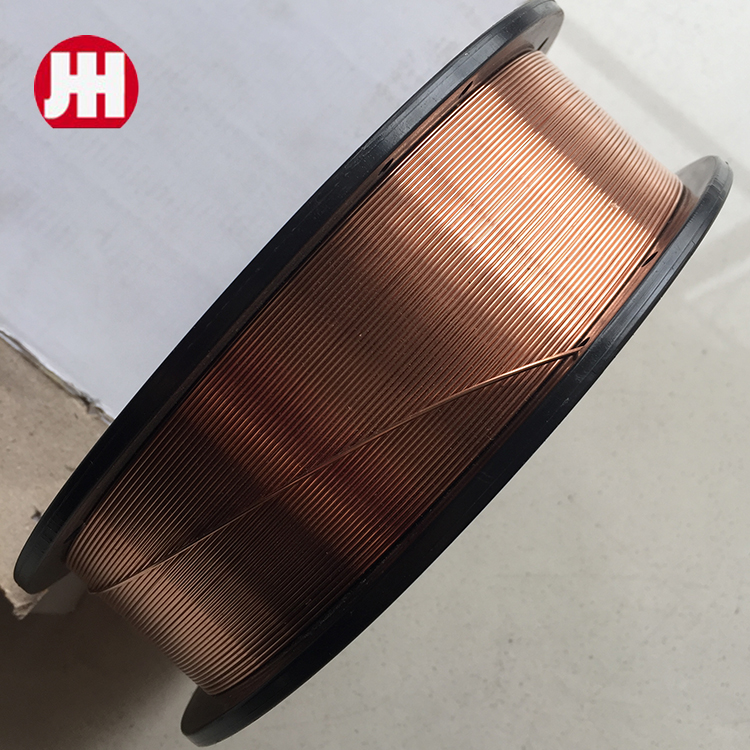

Product Showcase: Premium Co2 Solid Welding Wire

HEBEI YUJINHONG TECHNOLOGY proudly presents our flagship product: Co2 Solid Welding Wire Solder Wire ER70S-6. This 500MPa level carbon steel wire is engineered for excellence in demanding industrial applications. Specifically formulated for CO2 or 80%Ar + 20%CO2 gas shielded arc welding, this premium solid MIG wire offers numerous advantages:

- Minimal welding spatter for cleaner operations

- Exceptional bead appearance with high cladding efficiency

- Reduced porosity sensitivity in weld metal

- Superior positional welding capabilities

- Consistent performance across varying base materials

Solid MIG Wire Technical Parameters

The performance characteristics of MIG solid welding wire depend on specific chemical composition and mechanical properties. This table presents comparative industry-standard parameters for various grades:

| Parameter | ER70S-6 | ER80S-D2 | ER308L | Industry Standard |

|---|---|---|---|---|

| Diameter Range (mm) | 0.6-1.6 | 0.8-1.6 | 0.8-1.6 | 0.6-2.4 |

| Tensile Strength (MPa) | 500-580 | 550-690 | 550-650 | 480-760 |

| Yield Strength (MPa) | ≥420 | ≥500 | ≥400 | 380-660 |

| Elongation (%) | 22-28 | 19-25 | 35-45 | 18-40 |

| Carbon Content (%) | 0.06-0.15 | 0.07-0.12 | 0.03 max | 0.03-0.25 |

| Silicon Content (%) | 0.80-1.15 | 0.65-0.85 | 0.30-0.65 | 0.40-1.25 |

| Optimal Shielding Gas | CO2 or Ar/CO2 | Ar/CO2 | Ar/O2 or Ar/CO2 | Varies by application |

Industrial Applications of Welding Solid Wire

The versatility of solid MIG wire extends across multiple industrial sectors, with particular dominance in:

Automotive Manufacturing - High-strength MIG solid welding wire is essential for chassis assembly and body-in-white construction, offering rapid deposition rates and consistent quality demanded by automated production lines.

Structural Steel Fabrication - ER70S-6 grade welding solid wire meets critical building codes and seismic requirements for high-rise structures and bridge components.

Shipbuilding - Marine-grade alloys in solid wire format provide the corrosion resistance and fatigue strength necessary for hull construction and offshore platform applications.

Heavy Equipment Manufacturing - The mining and agricultural sectors utilize specialized MIG wires that withstand extreme abrasion and impact forces.

Technical Evolution of Solid Wire Welding

The ongoing development of solid MIG wire technology has focused on three key areas according to research published in the Journal of Materials Processing Technology:

- Surface Engineering - Advanced copper coating technologies reduce friction through feed systems while maintaining optimal electrical conductivity.

- Alloy Optimization - Nanoscale manipulation of titanium and boron additives enhances grain structure stability at elevated temperatures.

- Manufacturing Precision - Diameter tolerances have tightened to ±0.01mm through laser measurement systems, ensuring arc stability during high-speed welding.

Leading manufacturers including HEBEI YUJINHONG TECHNOLOGY now implement electromagnetic cleaning processes that reduce metallic inclusions to

Professional FAQ: Solid MIG Wire Technical Considerations

1. What factors determine optimal solid MIG wire diameter selection?

Diameter selection depends on material thickness (0.6-0.8mm for thin gauge automotive panels, 1.2-1.6mm for structural steel), welding position, and amperage range. Excessive diameter increases spatter in vertical-up positions, while insufficient diameter limits deposition rates in flat positions.

2. How does silicon content affect MIG solid welding wire performance?

Silicon acts as a powerful deoxidizer (optimal range 0.8-1.05% for ER70S-6). Adequate silicon reduces porosity but excess silicon increases fluidity, compromising positional control. Premium wires balance manganese (1.40-1.85%) and silicon for optimal wetting action.

3. What certification standards apply to structural welding solid wire?

Critical applications require compliance with AWS A5.18 (carbon steel), AWS A5.28 (low alloy), or EN ISO 14341-A/B classifications. Nuclear and pressure vessel applications additionally demand ASME SFA-5.18 conformance with supplementary impact testing at -40°C.

4. How should solid MIG wire be stored to maintain quality?

Maintain original packaging at 15-25°C with

5. What distinguishes ER70S-3 from ER70S-6 MIG wires?

ER70S-6 contains higher manganese/silicon content (Mn: 1.4-1.85%, Si: 0.8-1.15% vs Mn: 1.2-1.6%, Si: 0.6-0.85% for S-3). This provides superior deoxidation for rusty or primed materials while increasing fluidity for improved bead appearance. S-6 typically requires lower wire feed speeds for equivalent deposition.

6. What post-weld treatments maximize solid wire joint integrity?

Critical welds benefit from stress-relieving heat treatment at 590-650°C for 1 hour per 25mm thickness. Peening improves fatigue resistance by 25-40% when applied properly during cooling between 150-300°C. For painted assemblies, zinc-rich primers prevent underfilm corrosion at the weld toe.

7. How do advanced solid MIG wires reduce operator fatigue?

Modified flux-core formulations with reduced fume generation (

Industry Certifications and Quality Assurance

HEBEI YUJINHONG TECHNOLOGY'S manufacturing facilities maintain ISO 9001:2015 quality management certification with supplemental AWS B5.16 compliance. Our solid MIG wire undergoes rigorous quality testing:

- Chemical analysis via optical emission spectrometry (OES) with 0.001% precision

- Mechanical testing using 200-ton universal tensile machines

- Surface inspection through automated laser profilometry

- Spool integrity testing at 3000 rpm feed rates

- Weld performance validation per AWS C1.1 M/C1 procedures

Technical References & Industry Publications

This article incorporates technical data from authoritative welding publications:

1. "Advanced GMAW Process Optimization" - Welding Journal Research Supplement, 2023 - https://www.aws.org/wj/supplement

2. "Consumable Selection for Critical Fabrication" - IIW Document XII-2203-22 - https://www.iiwelding.org/docs

3. ASM Handbook Volume 6: Welding, Brazing and Soldering - ASM International

4. "Developments in Steel Welding Technology" - Materials Performance Journal, 2024 - https://www.nace.org/resources/publications/mp

-

High-Quality Welding Electrodes 4.0mm*400mm for Industrial Use | Steel Tools ChinaNewsNov.24,2025

-

Explore the Benefits and Uses of 2.6mm Welding Electrode 6013 | Global GuideNewsNov.23,2025

-

Understanding CO2 Welding Wire Price: Global Impact, Trends, and TipsNewsNov.22,2025

-

Top Guide to Welding Wires CO2 – Specifications, Benefits & Industry UsesNewsNov.22,2025

-

Comprehensive Guide to Welding Electrode 6011 – Global Applications & BenefitsNewsNov.21,2025

-

AWS E6013 Welding Rod-HEBEI YUJINHONG TECHNOLOGY CO.,LTD.|All-Position Carbon Steel ElectrodeNewsNov.21,2025