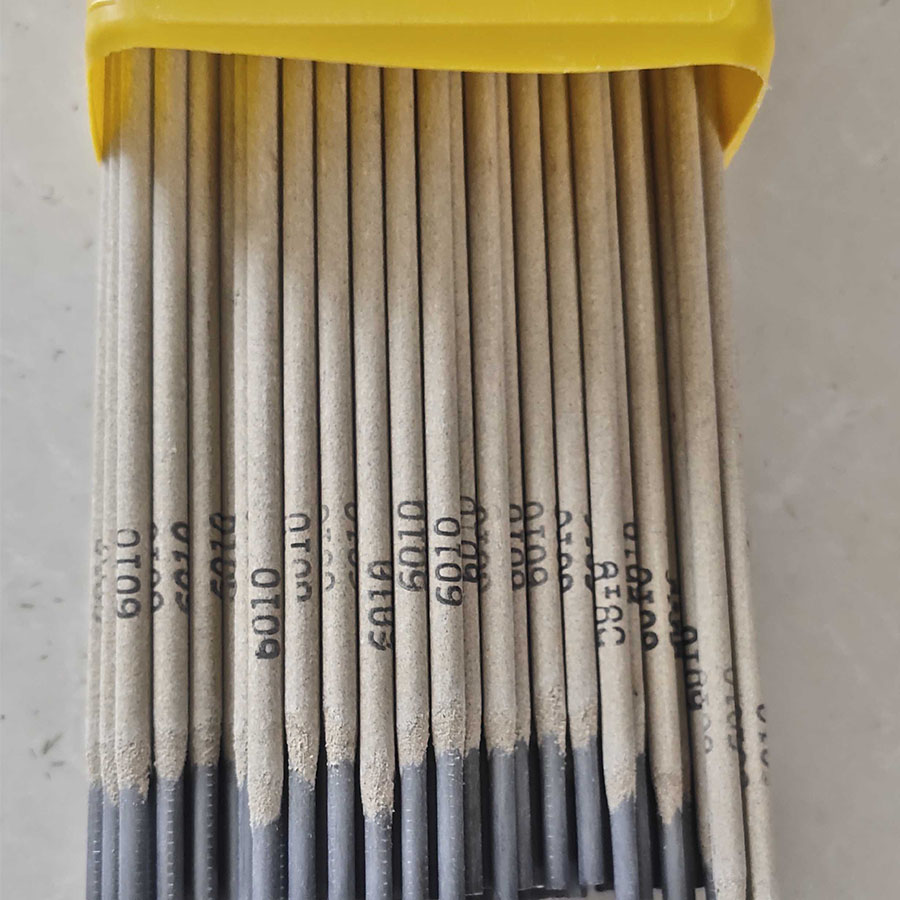

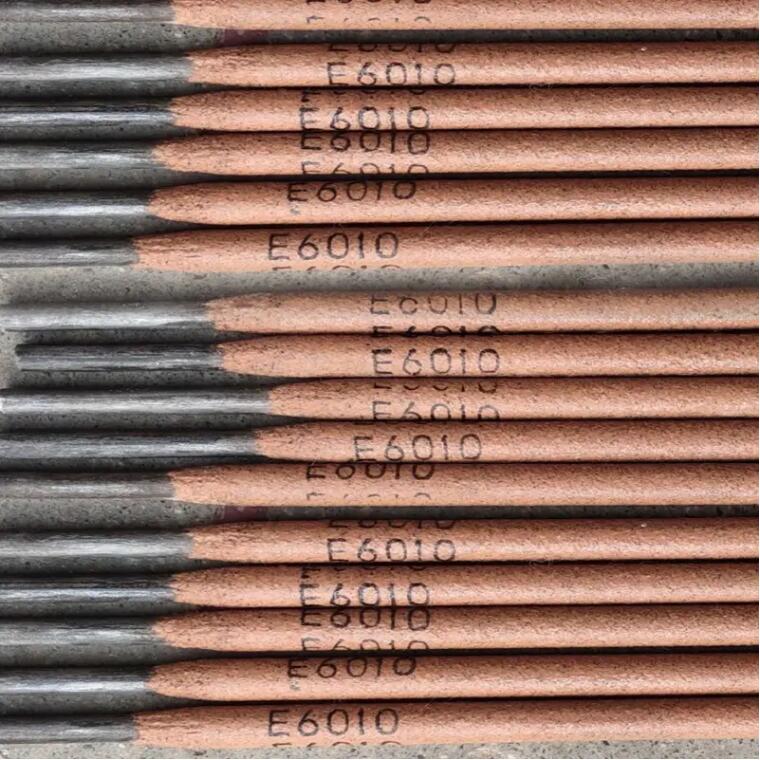

Cellulose Electrode E6010 - Deep Penetration, All-Position

Every few months I visit a pipeline jobsite and, to be honest, the same stick keeps showing up in the rod cans. It’s the cellulose electrode e6010—the old faithful for open-root passes and quick tie-ins. Trends come and go, but a deep‑digging, fast‑freezing, vertical‑down electrode still pays the bills in cross‑country pipeline and field maintenance.

What’s happening in the market

Pipeline owners keep pushing for fewer repairs after first hydrotest, and contractors are chasing productivity. That’s why the cellulose electrode e6010—especially the high cellulose sodium type—remains a staple: aggressive penetration, forgiving on less‑than‑perfect prep, and fast downhill travel speed. Supply has stabilized post-pandemic, and I’m seeing more requests for batch traceability and API 1104 weld procedure qualifications bundled with deliveries. Surprisingly, even tank fabricators are revisiting cellulosic rods for certain vertical seams where speed matters.

Product snapshot: Cellulose Welding Rod E6010 for Carbon Steel Pipes

Origin: NO.368 YOUYI NORTH STREET, XINHUA DISTRICT, SHIJIAZHUANG CITY, CHINA. The coating is high cellulose sodium, tuned for vertical‑down root passes on carbon steel. Real-world users tell me it lights instantly on DCEP and holds a tight, digging arc that eats through mill scale. In fact, many customers say the puddle control feels “confident,” even on windy ROWs.

| Parameter | Typical value (≈, real-world may vary) | Notes |

|---|---|---|

| Classification | AWS A5.1 E6010 | Comparable cellulosic class |

| Polarity | DCEP (reverse) | Designed for vertical-down root |

| Diameters | 2.5 / 3.2 / 4.0 / 5.0 mm | Other sizes on request |

| Current (A) | 2.5: 50–90; 3.2: 70–130; 4.0: 90–160; 5.0: 130–210 | Set by joint and skill |

| Tensile / Yield / Elong. | ≥ 60 ksi / ≥ 48 ksi / ≥ 22% | AWS A5.1 minimums |

| Deposition efficiency | ≈ 60–65% | Typical for cellulosic |

| Storage | Dry room, sealed; avoid rebake > 60–70°C | Moisture is part of arc chemistry |

Where it excels

- Pipeline open-root and hot pass, downhill tie-ins

- Field repairs on carbon steel (even slightly rusty or painted edges—within reason)

- Vertical-down seams on tanks and structural bracing

Advantages: deep penetration, strong arc force, quick travel, fast-freezing slag, and good sidewall fusion. One caveat: it’s not a low-hydrogen rod, so procedure control and post‑weld inspection matter.

How it’s made and qualified (quick flow)

Materials: mild‑steel core wire + high-cellulose sodium coating with arc stabilizers and gas-formers. Methods: wire drawing → cleaning → flux mixing → extrusion → controlled bake (lower temp than low‑hydrogen rods) → marking → packaging. Testing: per AWS A5.1 tensile testing, bend tests; WPS/PQR as per ASME IX or API 1104 with RT/UT acceptance. Service life: sealed shelf life around 12 months; in use, the weld’s design life follows the project spec—pipeline operators typically assess with API 1104 and in‑service inspection regimes.

Vendor comparison (what buyers actually ask)

| Vendor | AWS Class | Sizes | Certs | Lead time | Customization |

|---|---|---|---|---|---|

| SteelToolsChina (this model) | E6010 | 2.5–5.0 mm | ISO 9001; batch COA | ≈ 2–3 weeks | Private label, box weight, diameter mixes |

| Global Brand A | E6010 | 3.2–5.0 mm | ISO 9001; MTC | ≈ 1–2 weeks | Standard packaging only |

| Regional Brand B | E6010 | 2.5–4.0 mm | Factory QA | ≈ 3–4 weeks | Limited diameters |

Customization, feedback, and a couple of quick case notes

Customization: diameter mixes per pallet, moisture‑controlled packaging, and print branding are common requests. Some buyers also ask for pre‑qualified WPS drafts aligned to ASME IX or API 1104 (handy starting point, though procedure qualification is ultimately on the fabricator).

Case #1 (pipeline, Central Asia): 3.2 mm for open‑root; RT acceptance 98.5% on first pass across 120 joints. Welders praised the arc “push.” Case #2 (tank repair, GCC): Vertical‑down seams, 4.0 mm; repair rate under 2% post‑hydro. A foreman told me, “Travel speed shaved a day off our schedule.”

Testing highlights from a recent batch: tensile 64–68 ksi, yield 50–53 ksi, elongation 24–27% (n=3), bend tests passed, visual/VT clean bead with minimal undercut at recommended amps.

If you need a fast, penetrating downhill stick for carbon steel, the cellulose electrode e6010 remains a safe, proven bet—especially when codes like API 1104 or ASME IX are in play and your crew is trained for open‑root technique.

Authoritative references

- AWS A5.1/A5.1M: Specification for Carbon Steel Electrodes for Shielded Metal Arc Welding.

- API 1104: Welding of Pipelines and Related Facilities.

- ASME Section IX: Welding, Brazing, and Fusing Qualifications.

- ISO 9001: Quality Management Systems — Requirements.

-

High-Quality Welding Electrodes 4.0mm*400mm for Industrial Use | Steel Tools ChinaNewsNov.24,2025

-

Explore the Benefits and Uses of 2.6mm Welding Electrode 6013 | Global GuideNewsNov.23,2025

-

Understanding CO2 Welding Wire Price: Global Impact, Trends, and TipsNewsNov.22,2025

-

Top Guide to Welding Wires CO2 – Specifications, Benefits & Industry UsesNewsNov.22,2025

-

Comprehensive Guide to Welding Electrode 6011 – Global Applications & BenefitsNewsNov.21,2025

-

AWS E6013 Welding Rod-HEBEI YUJINHONG TECHNOLOGY CO.,LTD.|All-Position Carbon Steel ElectrodeNewsNov.21,2025