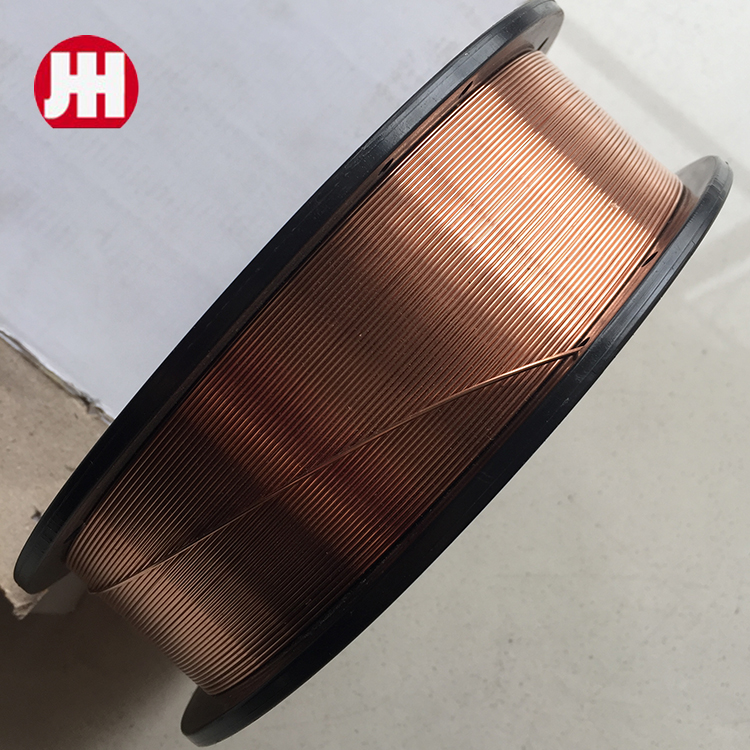

Solid MIG Wire – Low Spatter, Smooth Feed, Strong Welds

Choosing the Right Solid Mig Wire for Real-World Fabrication

Let me cut to the chase: wire quality shows up in your welds—bead shape, spatter, porosity, the whole story. The ER70S-6 grade from Shijiazhuang (Origin: NO.368 YOUYI NORTH STREET, XINHUA DISTRICT, SHIJIAZHUANG CITY, CHINA) is a 500 MPa-class carbon steel wire tuned for CO2 or 80%Ar + 20%CO2. In practice, that means consistent arc starts, tidy wetting, and—many customers tell me—surprisingly clean toes even on slightly rusty steel. I’ll share specs, test data, and a few shop-floor notes.

What it is (and why it works)

ER70S-6 leans on Si-Mn deoxidizers, so it’s forgiving on mill scale. Pair with DCEP, CO2 or 80/20 gas, and you get low spatter, all-position usability, and good fusion. To be honest, the bead aesthetics are often what win fabricators over.

Product specs at a glance

| Grade | ER70S-6 (AWS A5.18) / ISO 14341-A G3Si1 ≈ G4Si1 |

| Tensile Strength | ≥ 500 MPa (typical 520–560 MPa; real-world use may vary) |

| Yield / Elongation | ≈ 420 MPa YS; 22–28% EL |

| CVN Toughness | ≥ 27 J @ -20°C (typical) |

| Diameters | 0.8 / 0.9 / 1.0 / 1.2 / 1.6 mm |

| Polarity / Gas | DCEP; CO2 or 80%Ar + 20%CO2 |

| Chemistry (typ.) | C 0.08–0.12, Mn 1.4–1.85, Si 0.8–1.15 |

Process flow and quality checks

Materials: low-carbon steel rod → multi-stage drawing → controlled anneal → copper coating → precision spooling → vacuum packing with desiccant.

Methods: strict cast/helix control for smooth feeding; laser diameter monitoring; surface cleanliness checks.

Testing standards: AWS A5.18 / ISO 14341 classification; weld coupons tested to AWS D1.1 rules; tensile to ISO 6892-1; CVN to ISO 9016.

Typical service life of welded joints: decades when designed to code and protected; wire shelf life is long if kept dry, 10–32°C and ≤ 50% RH.

Where it shines

- General fabrication, frames, racking, agricultural machinery

- Automotive repair and light manufacturing

- Ship blocks, containers, steel structures (per AWS D1.1 procedures)

- Robotic cells needing predictable wire feed and arc stability

Customer feedback? “Lower cleanup on CO2,” one shop lead told me; another mentioned fewer tip burnbacks after switching to Solid Mig Wire with tighter cast/helix tolerances.

Vendor snapshot (quick comparison)

| Vendor | AWS Class | Diameters | Spools | Notes |

|---|---|---|---|---|

| SteelToolsChina ER70S-6 | ER70S-6 | 0.8–1.6 mm | 1 kg–15 kg (D200/D300) | Strong Si-Mn; custom labeling; ISO 9001 |

| Lincoln Electric L-56 | ER70S-6 | 0.6–1.6 mm | Various | Global availability; extensive data |

| ESAB AristoRod 12.50 | ER70S-6 equiv. | 0.8–1.6 mm | Spool/Drum | ASC deoxidation; robot-friendly |

Pricing and performance vary by lot, line, and gas mix; always validate on your procedure. For many shops, Solid Mig Wire with stronger deoxidizers pays back in prep-time saved.

Customization and quick cases

Customization: private-label packaging, tailored copper coat, drum supply for robots, and diameter-specific parameter guidance. Typical settings for 1.0 mm on mild steel: 18–23 V, 180–240 A, WFS around 6–9 m/min (tune to joint).

- Case A (container fab): switching to Solid Mig Wire cut spatter cleanup ≈ 25% on CO2.

- Case B (AG equipment): improved toe wetting on mill-scale plate, reducing undercut repairs by ≈ 18%.

Compliance, certificates, and documentation

Mill Test Certificate (EN 10204 3.1) available; meets AWS A5.18 ER70S-6 and ISO 14341. Many buyers request ISO 9001 QMS, and yes, WPS/PQR support is provided against AWS D1.1 or ISO steel codes. Actually, that paperwork often speeds audits.

Citations

- AWS A5.18/A5.18M: Specification for Carbon Steel Electrodes and Rods for Gas Shielded Arc Welding.

- ISO 14341: Welding consumables — Wire electrodes and weld deposits for gas shielded metal arc welding of non-alloy and fine grain steels.

- AWS D1.1/D1.1M: Structural Welding Code — Steel.

- ISO 6892-1: Metallic materials — Tensile testing — Part 1: Method of test at room temperature.

-

High-Quality Welding Electrodes 4.0mm*400mm for Industrial Use | Steel Tools ChinaNewsNov.24,2025

-

Explore the Benefits and Uses of 2.6mm Welding Electrode 6013 | Global GuideNewsNov.23,2025

-

Understanding CO2 Welding Wire Price: Global Impact, Trends, and TipsNewsNov.22,2025

-

Top Guide to Welding Wires CO2 – Specifications, Benefits & Industry UsesNewsNov.22,2025

-

Comprehensive Guide to Welding Electrode 6011 – Global Applications & BenefitsNewsNov.21,2025

-

AWS E6013 Welding Rod-HEBEI YUJINHONG TECHNOLOGY CO.,LTD.|All-Position Carbon Steel ElectrodeNewsNov.21,2025