E71T-1 Shielding Gas for Gas Shielded Cored Wire Welding Solutions

In recent years, e71t 1 shielding gas and gas shielded cored wire technology have become central within welding consumables for a wide scale of industries. With innovation and stricter demands for efficient, high-strength and cost-effective welding, the role of gas shielded technologies is more pivotal than ever. This article—penned by the technical team from HEBEI YUJINHONG TECHNOLOGY CO.,LTD.—dives deep into technical parameters, industry trends, core product info, expert FAQ, and multimedia data visualization for both practitioners and procurement professionals.

About HEBEI YUJINHONG TECHNOLOGY CO.,LTD.

HEBEI YUJINHONG TECHNOLOGY CO.,LTD. is a global leader in welding consumables, providing innovative solutions tailored to the needs of the steel and fabrication industries. Our flagship products like E71T-1C Gas Shield Flux Coated Welding Wire are developed with deep expertise and rigorous quality standards.

- Official Website: https://www.steeltoolschina.com

- Telephone: 0086-137 3972 7566

- Mobile: 0086-311-68035766

- Email: info@steeltoolschina.com

- Address: NO.368 YOUYI NORTH STREET, XINHUA DISTRICT, SHIJIAZHUANG CITY, CHINA

1. Industry Trends: The Evolution of E71T 1 Shielding Gas

The welding industry is experiencing continuous transformation with the adoption of advanced e71t 1 shielding gas solutions, particularly in shipbuilding, automotive, structural steel, pipeline, and heavy fabrication. As noted by scholars from Surface & Coatings Technology, “Flux cored arc welding (FCAW) stands out for its operational versatility and productivity, enabled by optimized gas shielding and wire composition.” Operators are increasingly demanding wires with stable arc, low spatter, high deposition, and excellent mechanical properties, which E71T-1C excels in (AWS A5.36 standard).

Statistics from industry forums highlight robust year-on-year growth in the adoption of gas shielded cored wire in the Asia-Pacific and North American markets (The Welder Magazine). Regulatory frameworks such as ISO 17632 and GB/T10045 E501T-1 have further standardized parameters for operator safety and weld mechanical properties.

2. Technical Parameters for E71T 1 Shielding Gas

Key specifications for e71t 1 shielding gas and gas shielded cored wire are fundamental for process control, weld integrity, and productivity. Below is a detailed table consolidating technical parameters from manufacturer datasheets and industry standards:

| Parameter | Typical Value | Unit | Description |

|---|---|---|---|

| Shielding Gas Type | CO2 (100%) / Ar+CO2 (75/25) | % | Recommended Atmosphere to Protect Weld Pool |

| Wire Diameter | 1.0 / 1.2 / 1.6 | mm | Common Wire Gauges |

| Current Range | 80–360 | Ampere | Operating Welding Current |

| Voltage Range | 16–38 | Volt | Arc Voltage Window |

| Polarity | DCEP (+) | - | Direct Current Electrode Positive |

| Deposition Efficiency | 85-90 | % | Material deposited vs. wire consumed |

| Diffusible Hydrogen | <10 | ml/100g | Indicates Crack Sensitivity |

| Tensile Strength | ≥500 | MPa | Ultimate Weld Tensile Strength |

| Impact Toughness | >27 | J @ -20°C | Low Temperature CVN Test |

Technical Trend Visualization

3. E71T-1C Gas Shield Flux Coated Welding Wire: Product Details

- Product Name: **E71T-1C Gas Shield Flux Coated Welding Wire**

- Codes/Certifications: GB/T10045 E501T-1; ISO 17632-A-T422PC2H10; NB/T 47018 E501T-1; AWS A5.36 E71T1-C1A2-CS1

- Typical Applications: Structural steel, pipelines, shipbuilding, heavy equipment, offshore & marine, bridges

- Features: Stable arc, high weld strength, excellent impact toughness, superior spatter control, ease of slag removal

- Product Page: E71T-1C Official Page

Key Technical Indicators

Wire Diameter and Weld Process Window

4. Applications and Advantages of Gas Shielded Cored Wire

- Shipbuilding & Offshore Structures: Provides superior weld metal toughness vital for marine environments, reducing the risk of brittle fracture. (ResearchGate Study)

- Infrastructure & Bridges: Enables high-efficiency fillet and butt welds for heavy sections with low hydrogen cracks.

- Pipe & Tank Fabrication: e71t 1 shielding gas ensures minimal porosity and uniform mechanical strength around circumferential welds.

- Automotive & Rail: Increases process productivity and adaptability for both robotics and manual welding. (AWS White Paper)

- General Steel Construction: Delivers stable arc performance and visually clean, low-spatter welds meeting ISO/AWS international norms.

5. Frequently Asked Questions: Expert Q&A

A1: It is specifically designed for welding carbon steels and low alloy steels, including structural steels in ships, bridges, vehicles and machinery (AWS Forum).

Q2: What shielding gas is required for optimal performance?

A2: Use 100% CO2, or 75% Ar + 25% CO2 mix. Each atmosphere subtly affects arc stability, bead shape, and strength characteristics.

Q3: What are the available wire diameters and how to select them?

A3: Common diameters include 1.0 mm, 1.2 mm, 1.6 mm. Thicker wires are suited to higher currents and thicker material sections.

Q4: What mechanical properties does E71T-1C typically achieve?

A4: Yield strength ≥420 MPa; tensile strength ≥500 MPa; elongation ≥22%; impact toughness >27J at -20°C.

Q5: What standards/certifications are met?

A5: Complies with GB/T10045 E501T-1; ISO 17632-A-T422PC2H10, AWS A5.36 E71T-1C1A2-CS1, and NB/T 47018.

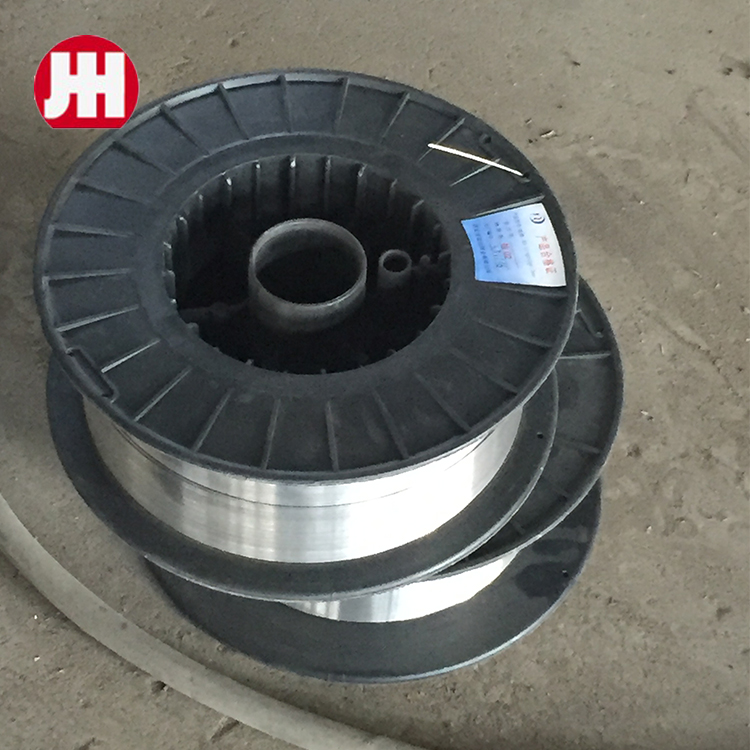

Q6: How is e71t 1 shielding gas delivered and stored?

A6: Supplied on spools/drums, store in dry environments & avoid exposure to humidity for best shelf life and weld quality.

Q7: What welding positions are supported?

A7: Designed for all positional welding—flat, horizontal, vertical, and overhead—thanks to fast-freezing slag and finely balanced composition.

6. Why Choose HEBEI YUJINHONG TECHNOLOGY CO.,LTD.?

- Proven Quality: Adheres to the most stringent international norms, as cited on our website.

- Extensive Customer Support: 24/7 technical response, application guidance, and tailored welding consultations for e71t 1 shielding gas.

- Global Export Experience: Efficient logistics across 56+ countries with stable, long-term client partnerships.

- Continuous R&D: Regular engagement with university welding research groups and forums (WE Blog UK).

7. Ordering & Contact

- Visit Product Page: E71T-1C Gas Shield Flux Coated Welding Wire

- Phone: 0086-137 3972 7566 | Mobile: 0086-311-68035766

- Email: info@steeltoolschina.com

- Address: NO.368 YOUYI NORTH STREET, XINHUA DISTRICT, SHIJIAZHUANG CITY, CHINA

8. References & Industry Authority

For further learning, technical discussion, and updates on e71t 1 shielding gas and related gas shielded cored wire technology, consult these industry-authoritative resources:

- AWS A5.36M/A5.36: Specification for Carbon and Low-Alloy Steel Flux Cored Electrodes

- Surface & Coatings Technology: "Effect of welding parameters and shielding gas on the performance of E71T-1"

- Welding Engineers UK: Comparison Insights

- AWS Welding Forum: "Flux cored (FCAW) E71T-1 basics"

- The Fabricator: The Progress of Flux-Cored Arc Welding

- ResearchGate: "Application of E71T-1C in Shipbuilding"

- AWS: Flux Cored Welding in Automotive Industry

-

High-Quality Welding Electrodes 4.0mm*400mm for Industrial Use | Steel Tools ChinaNewsNov.24,2025

-

Explore the Benefits and Uses of 2.6mm Welding Electrode 6013 | Global GuideNewsNov.23,2025

-

Understanding CO2 Welding Wire Price: Global Impact, Trends, and TipsNewsNov.22,2025

-

Top Guide to Welding Wires CO2 – Specifications, Benefits & Industry UsesNewsNov.22,2025

-

Comprehensive Guide to Welding Electrode 6011 – Global Applications & BenefitsNewsNov.21,2025

-

AWS E6013 Welding Rod-HEBEI YUJINHONG TECHNOLOGY CO.,LTD.|All-Position Carbon Steel ElectrodeNewsNov.21,2025