Top Manufacturers of Titanium Welding Rods for Quality Fabrication Solutions

The Rise of Titanium Welding Rod Manufacturers

In recent years, the demand for titanium welding rods has significantly increased due to the unique properties of titanium as a metal. Renowned for its high strength-to-weight ratio, outstanding corrosion resistance, and ability to withstand extreme temperatures, titanium has become a preferred material in various industries, including aerospace, automotive, medical, and marine. Consequently, the role of titanium welding rod manufacturers has expanded, providing essential materials for these sectors that require high-quality welding solutions.

The Importance of Titanium Welding Rods

Titanium welding rods are crucial for joining titanium parts together or for overlaying surfaces to enhance their properties. These rods are often used in processes such as TIG (Tungsten Inert Gas) welding, which is favored for its precision and ability to produce high-quality welds. The lightweight nature of titanium makes it ideal for applications where weight reduction is critical, such as in aerospace components where every gram counts.

Moreover, the corrosion resistance of titanium allows for its use in environments that are hostile to other metals, particularly in marine applications where saltwater exposure can lead to rapid degradation. Industries also benefit from titanium's biocompatibility, making it a standard material in the medical field for equipment and implants.

The Manufacturing Landscape

As the demand for titanium welding rods grows, so does the number of manufacturers stepping into this specialized market. These manufacturers are often at the forefront of technological advancements, utilizing state-of-the-art equipment and materials to produce rods that meet rigorous industry standards. The manufacturing process involves careful control of the composition and purity of titanium to ensure that the final product provides optimal performance during welding.

To differentiate themselves in a competitive market, many companies are investing in research and development to innovate new welding rod formulations that enhance their properties, such as improved arc stability, better feedability, and enhanced resistance to welding defects. Manufacturers are also focusing on sustainability practices, employing methods to minimize waste and energy consumption during production.

titanium welding rod manufacturers

Challenges in the Industry

Despite the positive outlook, titanium welding rod manufacturers face several challenges. One of the primary concerns is the fluctuating prices of titanium, which can affect production costs and pricing strategies. Additionally, the specialized nature of titanium welding means that manufacturers must invest in the training of skilled welders who can effectively handle and utilize these materials.

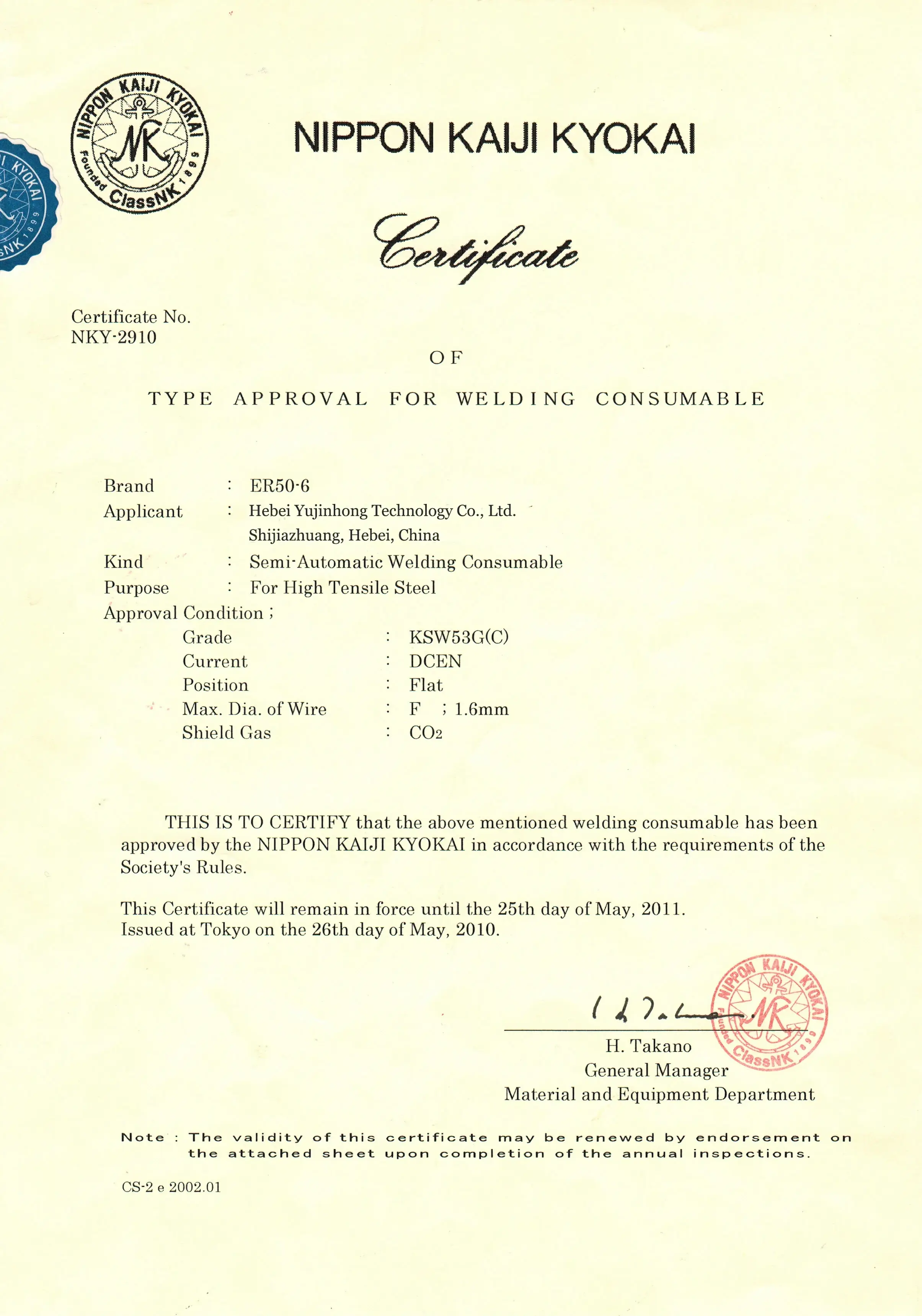

Another challenge is the need to adhere to strict regulations and standards, especially in industries like aerospace and medical. Manufacturers must ensure that their products not only meet these standards but also undergo rigorous testing and certification processes to gain the trust of their customers.

The Future of Titanium Welding Rod Manufacturing

Looking ahead, the future appears promising for titanium welding rod manufacturers. As industries increasingly prioritize lightweight and durable materials, the relevance of titanium will continue to grow. Innovations in 3D printing and additive manufacturing are also opening new avenues for the use of titanium, as businesses explore more efficient ways to create complex structures and components.

Moreover, the expansion of renewable energy sectors, like wind and solar power, is likely to spur further demand for titanium products, including welding rods. With ongoing research into alloys and composites that incorporate titanium, manufacturers are well-positioned to capitalize on emerging opportunities that will arise in the coming years.

In conclusion, titanium welding rod manufacturers play a pivotal role in meeting the growing demands of various high-tech industries. With continued investments in technology, sustainability, and skilled labor, these manufacturers are set to lead the way in shaping the future of welding and metal fabrication. As the market evolves, staying ahead of trends and challenges will be crucial for sustaining growth and innovation in this dynamic field.

-

Premium 7018 Welding Rods Electrodes for Strong WeldsNewsJul.23,2025

-

E71T-1 Shielding Gas for Gas Shielded Cored Wire Welding SolutionsNewsJul.22,2025

-

Premium Submerged Arc Welding Wire | Efficient Quality SolutionNewsJul.21,2025

-

Premium Solid MIG Welding Wire - Strong, Low-Spatter WeldsNewsJul.21,2025

-

E71T-GS Self-Shielding Welding Wire | Gasless Outdoor UseNewsJul.20,2025

-

E312 Welding Electrode - High Corrosion Resistance & All-Purpose UseNewsJul.20,2025