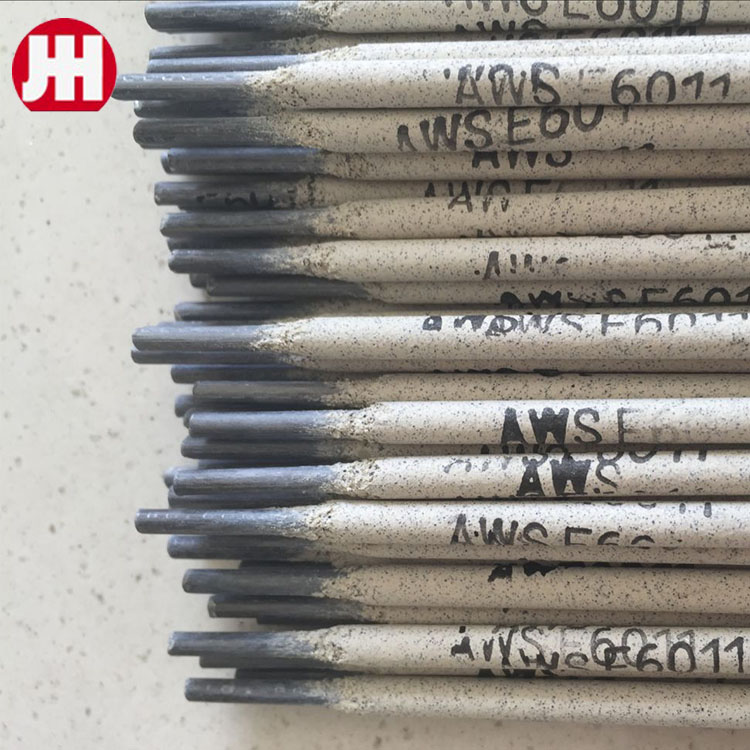

E6011 Welding Rod: Deep Penetration, All-Position?

Field-proven penetration: a reporter’s take on the e6011 welding rod

If you’ve welded in the rain, on a farm gate that’s seen better days, or under a truck chassis at 11 p.m., you already know why the e6011 welding rod still rides in so many toolboxes. It bites through rust, paint, and oil better than polite society would prefer. To be honest, that messy real-world flexibility is its magic. The product I looked at this month—Best Arc Welding Rods Cellulose AWS 6011 Electrode—comes from NO.368 YOUYI NORTH STREET, XINHUA DISTRICT, SHIJIAZHUANG CITY, CHINA, and it’s squarely aimed at field welders who need a reliable, all-position stick that lights even on a small AC buzz box.

What’s inside and why it matters

Technically, this is a high-cellulose potassium-coated electrode (AWS A5.1 E6011; GB/T 5117 E4311). The cellulose coating creates a forceful arc with deep penetration and fast-freeze slag—handy for vertical-down or out-of-position welds. Many customers say it’s surprisingly forgiving on fit-up; I’d add that puddle control is more of a rhythm than a science with these. AC or DC+ both run fine, which is a lifesaver when the only power source on site is a vintage transformer machine.

Key specifications (real-world use may vary)

| Standard | AWS A5.1 E6011; GB/T 5117 E4311; ASME SFA-5.1 |

|---|---|

| Core/Coating | Mild-steel core; high-cellulose K coating |

| Positions | All-position incl. vertical-down |

| Tensile Strength | ≥ 60 ksi (≈ 420 MPa); typical 62–72 ksi |

| Yield / Elongation | ≈ 48 ksi (330 MPa) / ≈ 22% |

| Diameters | 2.5, 3.2, 4.0 mm (others on request) |

| Amperage Window | 2.5 mm: 50–90A; 3.2 mm: 80–130A; 4.0 mm: 120–170A |

| Power Source | AC or DC+ |

Where it shines

- Maintenance and repair: farm equipment, gates, trailers, dozers

- Structural tack-in and patch work: angle, channel, HSS—especially outdoors

- Pipeline tie-ins and root passes on carbon steel (when codes allow)

- Dirty steel: rusted, lightly painted, or oily surfaces

In fact, the e6011 welding rod is the “get-it-done-now” option. Not pretty, but tough. Slag is thin and chips fast. Be ready for spatter, though—this isn’t a showroom bead.

Process flow and QA

Materials: low-carbon steel wire, cellulose-potassium coating; Methods: wire drawing, flux mixing, extrusion, calibrated drying; Testing: tensile and bend per AWS A5.1, diffusible moisture checks, arc-start consistency; Certifications: ISO 9001, mill heat traceability, batch certificates on request. Service life: sealed package ≈ 12–24 months; weld life depends on environment (coat or paint as needed).

Storage tip—actually important: do not high-bake like low-hydrogen rods. Keep sealed and dry; a light warm-up (around 40–50°C) may help in damp weather, but over-baking can dull performance.

Two quick field stories

- Coastal shipyard repair: crew burned 3.2 mm rods on AC to stitch corroded handrails; passed bend tests and visual per AWS D1.1, then primed same day. - Ranch gate fix: windy afternoon, power from a 6 kW generator; e6011 welding rod penetrated through scale without grinding the whole hinge area—customer called it “a day saver.”

Vendor snapshot and customization

Customization options include private labeling, carton branding, special cut lengths, and tuned amperage windows for specific diameters. Batch test sheets (tensile/bend) and third-party inspection can be arranged. Shipping from China with mixed-container111 loads is common; honestly, lead time is where vendors really differentiate.

| Vendor | Lead Time | MOQ | Certs | Notes |

|---|---|---|---|---|

| SteelToolsChina (Best Arc 6011) | ≈ 2–4 weeks ex-works | ≈ 1–3 tons | ISO 9001; AWS/ASME conformity | Private label, mixed DIAs in one lot |

| Domestic Brand A | Stock–2 weeks | By carton/pallet | AWS A5.1; local approvals | Fast replenishment, fewer custom options |

| Global Brand B | 3–6 weeks | Standard pallet | AWS/ASME; marine class | Premium pricing; broad distributor network |

Testing snapshot: typical all-weld tensile 430–500 MPa; bend 180° face/root without cracks per AWS A5.1. Some shops log room-temp impact ≈ 27 J; fair warning, this isn’t a low-hydrogen toughness rod.

Standards and references

- AWS A5.1/A5.1M: Specification for Carbon Steel Electrodes for Shielded Metal Arc Welding.

- ASME SFA-5.1: Carbon Steel Electrodes for SMAW (Section II, Part C).

- AWS D1.1/D1.1M: Structural Welding Code—Steel, procedure and performance qualification.

- Typical E6011 manufacturer datasheets (e.g., Lincoln Electric, ESAB) for operational ranges and technique notes.

-

High-Quality Welding Electrodes 4.0mm*400mm for Industrial Use | Steel Tools ChinaNewsNov.24,2025

-

Explore the Benefits and Uses of 2.6mm Welding Electrode 6013 | Global GuideNewsNov.23,2025

-

Understanding CO2 Welding Wire Price: Global Impact, Trends, and TipsNewsNov.22,2025

-

Top Guide to Welding Wires CO2 – Specifications, Benefits & Industry UsesNewsNov.22,2025

-

Comprehensive Guide to Welding Electrode 6011 – Global Applications & BenefitsNewsNov.21,2025

-

AWS E6013 Welding Rod-HEBEI YUJINHONG TECHNOLOGY CO.,LTD.|All-Position Carbon Steel ElectrodeNewsNov.21,2025