Production Description

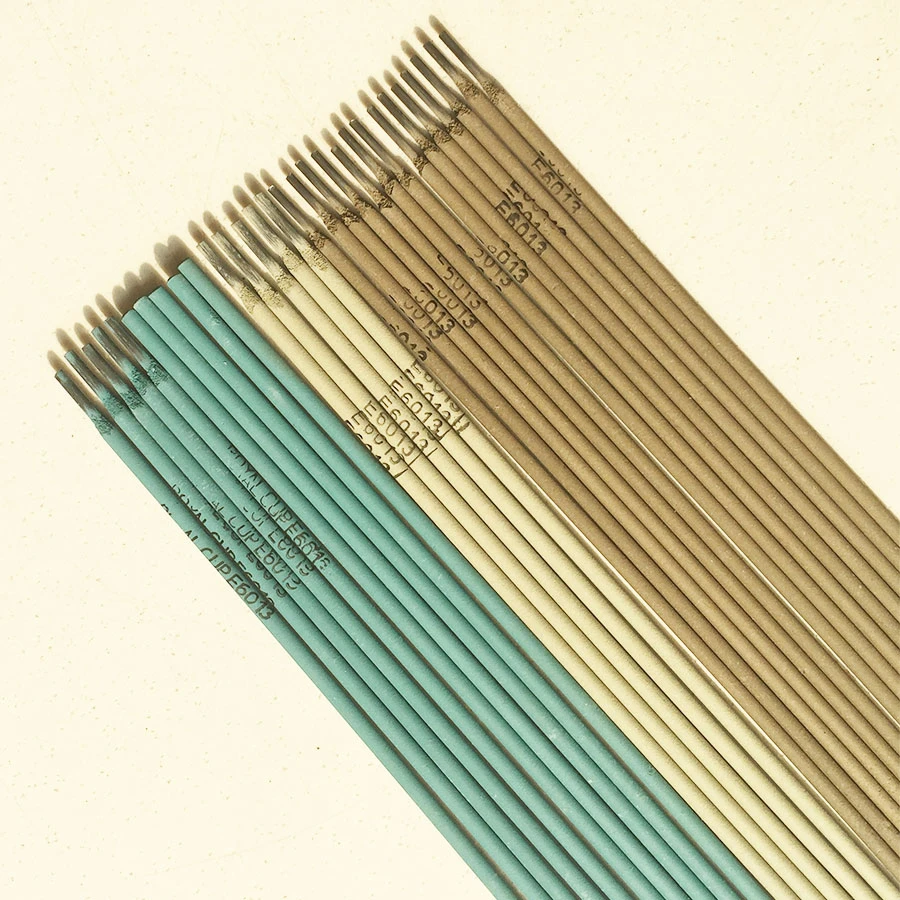

Cast Iron Welding Electrode Rod AWS ENiFe-CI.

Z408 is the cast iron electrode with nickel iron alloy core and strong reduction of graphite coating . It can be used in AC and DC dual purpose, has stable arc,and is easy to operate. The electrode has the characteristics of high strength, good plasticity, low linear expansion coefficient and so on. The crack resistance for grey cast iron is as much as that for Z308, while the crack resistance for nodular cast iron is more than Z308. For cast iron with higher phosphorus (0.2%P), it also has a good results and its tocutting performance is lower than Z308 andZ508 slightly. Z408 is used in the welding of gray iron and nodular cast iron for room

ATTENTION:

Before welding, the electrodes need to be baked for 1 hour with the temperature of 150±10℃ before using.

When welding ,it is appropriate to take narrow weld and each weld length should not exceed 50mm. Hammer the welding area lightly with a hammer immediately after welding in order to eliminate stress and prevent cracks.

Lower heat input is recommend.

Applicable process of cast iron welding rod

- Proper surface cleaning must be done before welding, and the welded joint should be obliquely cut into a U-shaped groove.

- Stop crack holes at both ends of the crack to prevent crack expansion during welding.

- When the angle of repair is not good, you can use WE100 welding rod to cold groove to form an effective U-shaped or V-shaped groove.

- Weld with as little current as possible, medium arc length, and slightly inclined to the welding direction.

- It is recommended to use short and thin welding beads and a narrow lateral swing welding torch to fill the weld joint before stopping arc welding. Usually no heat treatment is required and the parts are allowed to cool slowly.

Cast iron is an iron-carbon alloy with a carbon content greater than 2%. At present, more than 10 kinds of cast iron welding electrodes can be provided in China, which can be selected according to different cast iron materials, different cutting processing requirements and the importance of welding repair parts.

Cast iron is a material with poor weldability due to its high carbon content, uneven structure and low plasticity. Defects such as white spots, cracks, and pores are easy to occur during the welding process. Therefore, cast iron welding repairs require a high degree of welder technical proficiency. Cast iron welding repairs can be roughly divided into preheat welding and cold welding.

Chemical Composition: %

|

C |

Mn |

Si |

S |

Fe |

Ni |

Cu |

The mass of other elements |

|

0.35-0.55 |

≤2.3 |

≤0.75 |

≤0.025 |

3.0-6.0 |

60-70 |

25-35 |

≤1.0 |

WELDING REFERENCE CURRENT: (AC,DC+)

|

Electrode diameter(mm) |

3.2 |

4.0 |

5.0 |

|

Length (mm) |

350 |

350 |

350 |

|

Welding current(A) |

90-110 |

120-150 |

160-190 |

Specification & Package

2.5mm (3/32”) x 300/350mm; 2.5kgs/box, 20kg(8boxes) per carton.

3.2mm (1/8”) x 350mm; 5kgs/box, 20kg(4boxes) per carton.

4.0mm (5/32”) x 400mm; 5kgs/box, 20kg(4boxes) per carton.

OEM/ODM Package Available:

NW: 20.00KG,GW: 20.40KG,

we also can do different kgs package, plastic bag package,

we can print the package as your requests, we have professional designer to make the package design with your brand & LOGO.

Product Video

Visit & Exhibition

Welcome to visit us for a friendly and long term cooperation, please tell us your time schedule, we will arrange for you. we will also join the relate exhibitions, we can meet each other on the exhibition. Friendship first, and business is professional, you can trust us forever.

Do you have the following trouble when order the products?

1.Is the Supplier Reliable?

We produce this products more than 30 years, we have advertise on Alibaba, Made-in-China, after you place the order, whenever you want to see the production, we can send you video or picture to check. Our export team also have more than 15 years experience, we can solve all the problem you may meet in business. Welcome to visit us.

2.Is the Quality Stable?

We do test randomly in production, and test shipment before ex works. We have professional QC workers and high level test equipment, to assure each shipment in good quality.

3.Is the Payment Safe?

We choose one of the largest bank in China, to assure your payment will arrive in safe condition, and all of the benefit company must send them the shipping document copy to bank for record.

4.Shipment Delivery?

Normally we can arrange shipment in 15 days, if customize the package, shipment can be arranged in one month, please negotiate with our customer service, we will tell you a firm date after check our production and your order quantity.

Please don't hesitate to contact us

Sales Manager: Cherry Zhang

Tel: 0086-311-68035766

Fax: 0086-311-68035566

Mobile: 008613739727566

WhatsApp / Wechat: 008613739727566

Email: info@steeltoolschina.com

Send inquiry