Payvandlash novdasini tanlashda bir nechta omillarni hisobga olish kerak

Payvand chokini tanlashda bir nechta omillarni hisobga olish kerak:

- Asosiy metallning xususiyatlari.Siz qaysi turdagi metallni, qaysi qalinlikdagi metallni ishlatishingizni, asosiy metallning qalinligi, shakli va bo'g'inlarni o'rnatishni bilishingiz kerak.

- Mustahkamlik chegarasi.

Tensile strength refers to the maximum amount of stress that a material can experience while being either stretched or pulled before breaking or failing .

Yoriqlar kabi payvand choklarining uzilishlarini oldini olish uchun elektrodning minimal kuchlanish kuchi asosiy metallning minimal kuchlanish kuchiga mos kelishi kerak.

The welding electrodes used in most applications will be from either the 6000 or 7000 series. For example, an E6011 has a tensile strength of 60,000 psi. An E60 series welding rod will match the tensile strength of a mild steel according to Miller Welds.

- Payvandlash oqimi.

Elektrod uchun to'g'ridan-to'g'ri oqim va o'zgaruvchan tokdan foydalanish boshqacha. DC payvandlash yoyi barqaror, ammo qaysi biri qo'llanilishi elektrodning tabiati bilan bog'liq.

Masalan, J506 karbonli po'latdan asosiy elektrod ishlatiladi. J506 AC va DC uchun ishlatilsa-da, DC payvandlash yoyi barqaror. O'zgaruvchan tokdan foydalanilganda, yoy doimiy ravishda buziladi va payvandlash deyarli amalga oshirilmaydi.

- Payvandlash pozitsiyasi.

Qaysi elektrodni ishlatishni tanlashda siz payvandlash holatini ham hisobga olishingiz kerak. Payvandlash pozitsiyasi burg'ulovchi tomonidan payvandlash paychalarining yotqizilgan yo'nalishini bildiradi.

Eng ko'p ishlatiladigan payvand choklari barcha pozitsiyali payvandlash paychalariningdir. 4 ta asosiy payvandlash pozitsiyasi mavjud.

Flat, Horizontal, Vertical, Overhead

Sotilgan payvand choklarining ko'pchiligi to'liq pozitsiyali elektrodlardir, lekin siz sotib olgan asbob-uskunalar bilan ishlayotganingizda elektroddagi 4 yoki 5 raqamli raqamga qarash hali ham to'lanadi.

- Spetsifikatsiya va xizmat ko'rsatish shartlari.

Qaysi o'lchamdagi payvandlash tayog'idan foydalanishim kerak?

Odatda payvandlash paychalarining qalinligi siz ishlayotgan metallning qalinligi bilan mos kelishi kerak.

Payvandlash tayog'ining xavfsiz ishlashi mumkin bo'lgan oqim miqdori uning diametriga bog'liq.

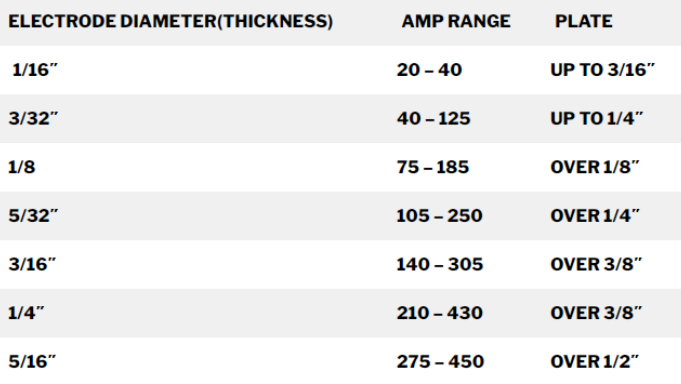

You can see the welding rod size charts that show the relationship between welding rod diameter and amperage, including this one produced by Firepower.

You can see in the chart that the welding rods range in size 5/64” in diameter to 5/32” in diameter.

Jadvalda, shuningdek, siz payvand qiladigan asosiy metallning mos keladigan tavsiya etilgan plastinka qalinligi ko'rsatilgan.

You will notice in this chart that there are welding rods ranging from 1/16” in diameter all the way up to 5/16” in diameter. Their chart looks something like this:

- Tqoplama materiallari

Qoplama materiali

American Welding Society (AWS) tasniflash tizimiga kiritilgan payvandlash novdalarida 8 xil turdagi qoplamalar qo'llaniladi.

The coating material will determine which type of current, AC, DC+, or DC- that you will be using. As an example, high titania sodium and high titania potassium coatings are both compatible with AC current, but if you’re using DC- (direct current, negative polarity) then you will need to use a high titania sodium.

- Ekologik mehnat sharoitlari.

E6013 elektrodi:

60 000 psi kuchlanish kuchiga ega: uni yumshoq po'lat bilan ishlatish uchun juda mos keladi

To'liq pozitsiyali elektrod: bu elektrod tekis, gorizontal, vertikal va tepalik holatida ishlatilishi mumkin.

Yuqori titanium kaliydan tayyorlangan qoplamaga ega: AC va DC+ tok bilan mos keladi

Ko'pgina boshlang'ich darajadagi payvandlash mashinalari o'zgaruvchan tok bilan ishlaydi. AC oqimiga mos keladigan payvandlash tayog'ini topish qiyin emas, chunki 8 ta payvandlash qoplama materiallaridan 6 tasi o'zgaruvchan tok bilan ishlaydi. E6013 elektrodlarini ishlatish qulayligining yana bir sababi shundaki, u E6011 elektrodiga qaraganda kamroq cüruf ishlab chiqarishga qodir yumshoq yoy hosil qiladi.

The arc of the E6013 also doesn’t penetrate through the base metal quite as easily as the E6011 does, leaving some room for error for an operator who hasn’t yet gotten a feel for how closely the arc should be held from the base metal.